Fracture toughness testing of aerospace materials

The Crucial Role of Fracture Toughness Testing in Aerospace Materials Ensuring Reliability and Safety

In the aerospace industry, materials play a critical role in ensuring the safety and performance of aircraft, spacecraft, and other related equipment. One of the most important properties of these materials is their fracture toughness, which measures their ability to resist cracking and breaking under stress. Fracture toughness testing of aerospace materials is a laboratory service that evaluates the materials resistance to crack propagation, thereby predicting its performance in real-world conditions.

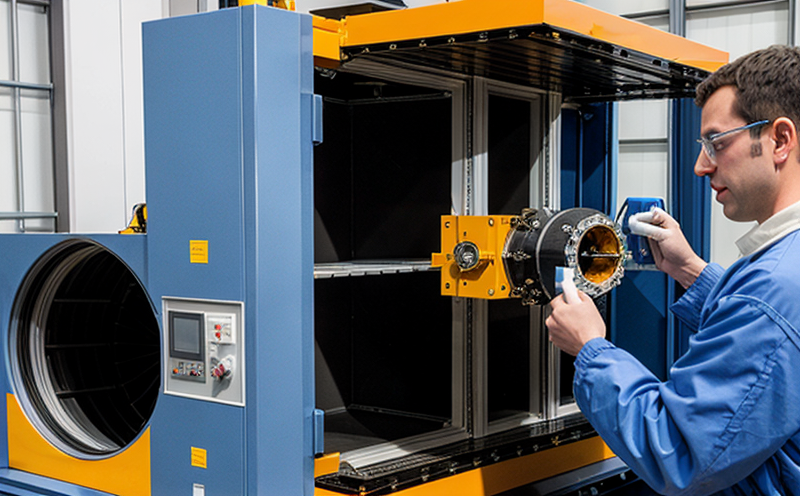

As an industry leader in providing laboratory services, Eurolab offers comprehensive fracture toughness testing of aerospace materials. Our state-of-the-art facilities and experienced team ensure accurate and reliable results, enabling businesses to make informed decisions about their products and materials. In this article, we will delve into the importance of fracture toughness testing, its advantages, and how it can benefit your business.

Why Fracture Toughness Testing is Essential for Aerospace Materials

Fracture toughness testing is crucial in the aerospace industry due to several reasons

Safety Ensuring that materials used in aircraft and spacecraft are reliable and safe is paramount. Fracture toughness testing helps identify potential weaknesses, thereby preventing catastrophic failures.

Performance Aerospace materials must withstand extreme temperatures, vibrations, and stresses during flight. Fracture toughness testing evaluates a materials ability to maintain its structural integrity under these conditions.

Regulatory Compliance Many regulatory bodies, such as the Federal Aviation Administration (FAA), require aerospace manufacturers to demonstrate the fracture toughness of their materials.

Advantages of Using Fracture Toughness Testing of Aerospace Materials

Eurolabs fracture toughness testing services offer numerous benefits for businesses in the aerospace industry

Key Benefits

Improved Safety Our testing helps identify potential weaknesses, ensuring that materials meet safety standards.

Enhanced Performance By evaluating a materials resistance to crack propagation, we can predict its performance under real-world conditions.

Compliance with Regulations We ensure that our results meet the requirements of regulatory bodies like the FAA.

Reduced Costs Identifying potential issues early on saves time and resources in the long run.

Increased Efficiency Our services enable businesses to make informed decisions, streamlining their development process.

Competitive Advantage Companies that invest in fracture toughness testing demonstrate a commitment to quality and safety.

How Eurolabs Fracture Toughness Testing Services Can Benefit Your Business

Our laboratory services are designed to meet the unique needs of the aerospace industry. By partnering with us, you can

Ensure Regulatory Compliance Our results meet or exceed regulatory requirements, giving you peace of mind.

Improve Material Selection We help you choose materials that meet your performance and safety standards.

Reduce Development Time By identifying potential issues early on, we enable faster development cycles.

Enhance Product Quality Our testing ensures that your products meet the highest standards of quality and safety.

Frequently Asked Questions

What is fracture toughness testing?

Fracture toughness testing evaluates a materials resistance to crack propagation under various loads, such as tension, compression, or shear.

Why is fracture toughness important in aerospace materials?

Fracture toughness is crucial in ensuring the safety and performance of aircraft and spacecraft. It helps predict how materials will behave under real-world conditions.

What methods do you use for fracture toughness testing?

We employ various techniques, including single-edge notch bend (SENB), double-edge notch tension (DENT), and compact compression (CC).

How long does the testing process take?

The duration of our services varies depending on the type of material and test required. Our experienced team will provide you with a tailored timeline for your specific needs.

What kind of reporting can I expect from Eurolabs fracture toughness testing services?

We provide comprehensive reports that include detailed results, recommendations, and explanations of our findings.

Conclusion

Fracture toughness testing is an essential service in the aerospace industry, ensuring the safety and performance of materials used in aircraft and spacecraft. By partnering with Eurolab, you can trust that your products meet the highest standards of quality and safety. Our state-of-the-art facilities, experienced team, and comprehensive services make us the ideal choice for businesses seeking reliable results.

Dont compromise on the safety and reliability of your aerospace materials. Choose Eurolabs fracture toughness testing services today and ensure a competitive advantage in the industry.