Fracture toughness of high-strength steels

Unveiling the Secrets of High-Strength Steels Unlocking Fracture Toughness

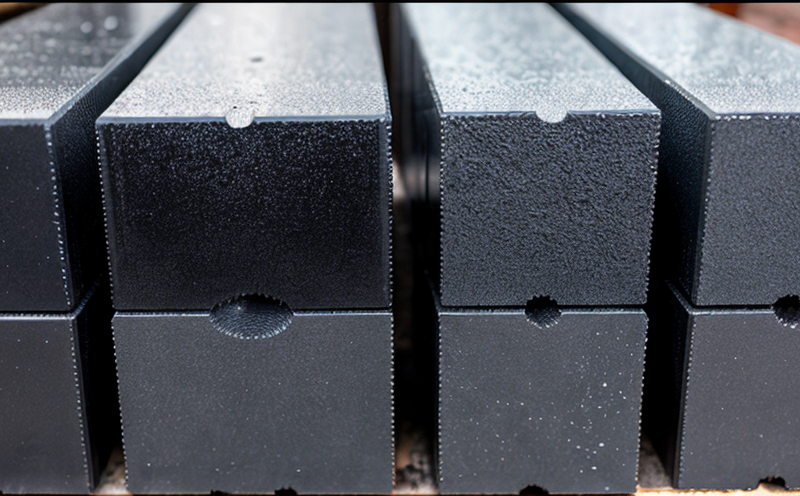

In todays fast-paced industrial landscape, businesses operating in various sectors, including aerospace, automotive, and construction, heavily rely on high-strength steels for their structural integrity and durability. However, the increasing demand for lighter, stronger, and more efficient materials has also raised concerns about their susceptibility to cracking and fracture under various stress conditions. This is where Fracture toughness of high-strength steels comes into play a critical property that ensures these materials can withstand harsh environmental conditions without compromising their structural integrity.

What is Fracture Toughness?

Fracture toughness, often denoted by the symbol K1c (or CTOD for cleavage tension opening displacement), represents a materials ability to resist fracture under stress. It is an essential parameter that defines a materials resistance to crack growth and propagation in the presence of external loads or environmental factors. For high-strength steels, determining their fracture toughness is crucial to predict their performance under various operational conditions.

Why Fracture Toughness Matters

Fracture toughness of high-strength steels is vital for businesses operating in industries where material failure can have catastrophic consequences. Some key reasons why it matters include

Prevention of Material Failure By understanding a materials fracture toughness, manufacturers and engineers can design structures that are less prone to cracking and failure, thereby preventing costly downtime and potential accidents.

Improved Safety Standards In high-risk industries such as aerospace and construction, the ability to predict and mitigate material failure is paramount. Fracture toughness testing ensures that materials meet or exceed safety standards, safeguarding peoples lives and minimizing liability risks.

Optimized Material Selection By understanding the fracture toughness of different high-strength steel grades, businesses can make informed decisions about which materials to use in their applications, reducing the risk of premature failure and associated costs.

Enhanced Product Reliability Materials with high fracture toughness are more likely to withstand operational stresses and environmental factors without compromising their structural integrity. This enhances product reliability and longevity, improving overall customer satisfaction and loyalty.

The Eurolab Advantage

At Eurolab, we provide a comprehensive laboratory service that enables businesses to assess the Fracture toughness of high-strength steels with accuracy and precision. Our state-of-the-art facilities and expert team ensure that our clients receive timely, reliable, and actionable results that meet or exceed industry standards.

Benefits of Choosing Eurolab for Fracture Toughness Testing

Comprehensive Service Offering We provide a range of testing services tailored to specific client needs, including Charpy V-notch impact tests, drop weight test, and instrumented indentation (Vickers) hardness testing.

Expertise in High-Strength Steel Analysis Our team consists of experienced materials scientists with extensive knowledge in high-strength steel analysis and fracture mechanics. This ensures that our clients receive expert advice and actionable results.

ISO/IEC 17025 Accreditation Eurolab is accredited to the highest international standards, guaranteeing that our testing services meet or exceed client expectations and regulatory requirements.

Timely Results Delivery We understand the importance of timely results in meeting project deadlines. Our efficient testing protocols ensure that clients receive their reports within agreed-upon timeframes.

QA Fracture Toughness of High-Strength Steels

Q What types of materials can be tested for fracture toughness at Eurolab?

A We test various high-strength steel grades, including but not limited to, aerospace alloys (e.g., 4130, 4340), automotive steels (e.g., SAE 1045, AISI 4140), and construction materials.

Q How do I determine the correct testing methodology for my material?

A Our experienced team will work with you to select the most suitable testing protocol based on your specific requirements and industry standards.

Q What information do I receive from a fracture toughness test report?

A Our comprehensive reports include detailed analysis of your materials fracture toughness, along with recommendations for potential applications or improvements in material selection.

Q Can Eurolab provide expert advice on interpreting the results of my fracture toughness tests?

A Absolutely. Our team is committed to supporting clients through every stage of testing and interpretation, ensuring that they receive actionable insights that inform their decision-making processes.

In conclusion, understanding the Fracture toughness of high-strength steels is essential for businesses operating in industries where material failure can have severe consequences. At Eurolab, we provide a comprehensive laboratory service that helps clients assess and improve their materials performance under various operational conditions. Whether youre an aerospace manufacturer seeking to optimize structural integrity or a construction firm looking to enhance product reliability, our expert team and state-of-the-art facilities are committed to delivering timely, accurate results that drive business success.

Dont let material failure compromise your operations choose Eurolab for Fracture toughness of high-strength steels testing today.