Evaluating Leakage Resistance in Ceramic Capacitors

Evaluating Leakage Resistance in Ceramic Capacitors Why Its a Game-Changer for Businesses

As the demand for high-performance electronic devices continues to rise, manufacturers are under increasing pressure to ensure their products meet the highest standards of quality and reliability. One critical aspect that often goes overlooked is the evaluation of leakage resistance in ceramic capacitors. In this article, well delve into the importance of Evaluating Leakage Resistance in Ceramic Capacitors and why its essential for businesses to incorporate this laboratory service into their testing protocols.

What Is Evaluating Leakage Resistance in Ceramic Capacitors?

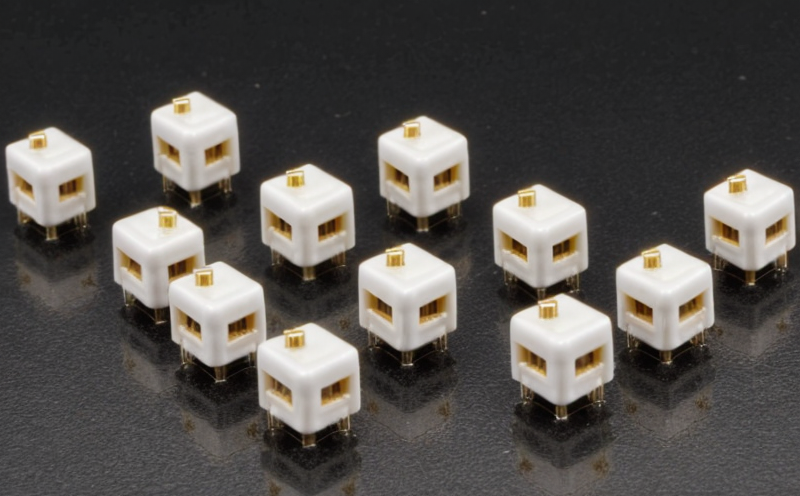

Leakage current, also known as leakage resistance, is a critical parameter that affects the overall performance and reliability of ceramic capacitors. It refers to the flow of electric current through the dielectric material between the two electrodes, causing energy losses and reducing the capacitors effectiveness. Evaluating leakage resistance in ceramic capacitors involves measuring the amount of electrical current leaking through the capacitor over a specified period.

Why Is Evaluating Leakage Resistance in Ceramic Capacitors Essential?

The consequences of inadequate leakage resistance evaluation can be severe. A capacitor with high leakage current may not function as intended, leading to premature failure and potentially catastrophic consequences in critical applications such as aerospace, automotive, or medical devices. In addition to the financial losses associated with product recalls and warranty claims, manufacturers may also face reputational damage and loss of customer trust.

Advantages of Using Evaluating Leakage Resistance in Ceramic Capacitors

Our laboratory service at Eurolab offers a range of benefits that can help businesses enhance their products performance, reliability, and safety. Here are some of the key advantages

Improved Product Reliability

Reduced risk of premature failure

Enhanced overall system reliability

Minimized downtime and maintenance costs

Increased Efficiency

Optimized capacitor design and selection

Reduced energy losses and heat generation

Improved system performance and efficiency

Compliance with Industry Standards

Ensures compliance with relevant industry standards (e.g., IEC, UL, MIL-STD)

Reduced risk of non-compliance and associated costs

Enhanced credibility and reputation in the market

Reduced Costs

Minimized warranty claims and product recalls

Reduced maintenance and repair costs

Improved overall cost-effectiveness

Enhanced Customer Satisfaction

Increased customer confidence in product reliability

Improved brand reputation and loyalty

Enhanced competitiveness in the market

How Does Evaluating Leakage Resistance in Ceramic Capacitors Work?

Our laboratory service involves a series of rigorous tests and evaluations to determine the leakage resistance of ceramic capacitors. Heres an overview of the process

Sample Preparation The capacitor samples are carefully prepared for testing, ensuring accurate and reliable results.

Leakage Current Measurement The leakage current is measured using advanced equipment and techniques, such as high-voltage probes and oscilloscopes.

Data Analysis The measurement data is analyzed to determine the leakage resistance of each capacitor sample.

Reporting A comprehensive report detailing the results, including any deviations from specifications or industry standards.

Frequently Asked Questions (FAQs)

Q What types of ceramic capacitors can be evaluated for leakage resistance?

A Our laboratory service at Eurolab supports a wide range of ceramic capacitor types, including MLCCs (Multilayer Ceramic Capacitors), C0G/NP0, and X7R/X5R.

Q How do I prepare my samples for testing?

A Please follow our sample preparation guidelines to ensure accurate and reliable results. If you have any questions or concerns, please contact us.

Q What is the typical turnaround time for evaluating leakage resistance in ceramic capacitors?

A Our standard turnaround time is X days, although expedited services may be available upon request.

Q Can I receive certification or documentation to support compliance with industry standards?

A Yes, we provide comprehensive reports and certificates of conformity to help you meet relevant industry standards.

Conclusion

Evaluating leakage resistance in ceramic capacitors is a critical aspect of ensuring product reliability, safety, and performance. Our laboratory service at Eurolab provides a cost-effective and efficient solution for businesses looking to enhance their products quality and competitiveness. By incorporating this service into your testing protocols, you can reduce the risk of premature failure, improve efficiency, and increase customer satisfaction.

Dont wait until its too late contact us today to learn more about our Evaluating Leakage Resistance in Ceramic Capacitors laboratory service and take the first step towards optimizing your products performance and reliability.