Measuring Electrolytic Capacitor Leakage at High Temperatures

Measuring Electrolytic Capacitor Leakage at High Temperatures A Crucial Service for Businesses

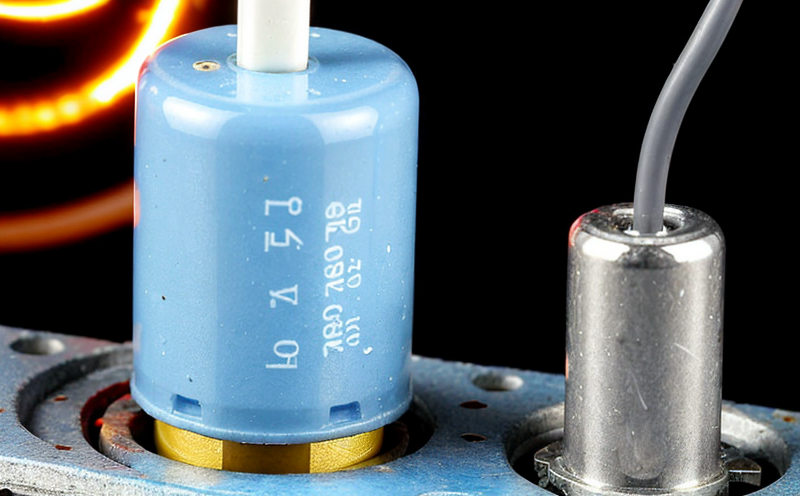

In the fast-paced world of electronics and electrical engineering, reliability and efficiency are paramount. One critical aspect that can make or break a products performance is the electrolytic capacitor, a crucial component in many electronic circuits. However, these capacitors are prone to leakage, especially at high temperatures, which can have devastating consequences on a devices functionality and lifespan.

At Eurolab, we understand the importance of ensuring the reliability and integrity of electronic components, particularly when it comes to measuring electrolytic capacitor leakage at high temperatures. Our laboratory service is specifically designed to identify potential issues before they cause problems, saving businesses time, money, and valuable resources.

What is Measuring Electrolytic Capacitor Leakage at High Temperatures?

Measuring electrolytic capacitor leakage at high temperatures involves assessing the electrical conductivity of a capacitor under simulated environmental conditions that mimic real-world usage. This process helps determine whether a capacitor can withstand extreme temperatures without compromising its performance or failing catastrophically.

Our laboratory employs state-of-the-art equipment to subject capacitors to various temperature settings, typically ranging from 85C to 105C (185F - 221F). By doing so, we can accurately measure the leakage current and identify potential issues before they become critical problems.

Why is Measuring Electrolytic Capacitor Leakage at High Temperatures Essential for Businesses?

The importance of measuring electrolytic capacitor leakage at high temperatures cannot be overstated. Here are some compelling reasons why businesses should prioritize this laboratory service

Key Benefits

Reduced Warranty Claims By identifying potential issues early on, businesses can minimize warranty claims and associated costs.

Improved Product Reliability Measuring electrolytic capacitor leakage at high temperatures ensures that products meet performance standards, reducing the risk of product failure.

Increased Efficiency By identifying and addressing problems before they cause issues, businesses can streamline production processes and reduce waste.

Compliance with Industry Standards Our laboratory service helps ensure compliance with industry regulations and standards, such as those set by UL (Underwriters Laboratories) and IEC (International Electrotechnical Commission).

Cost Savings Identifying potential problems early on can save businesses a significant amount of money in the long run.

What Can Measuring Electrolytic Capacitor Leakage at High Temperatures Tell Us?

Our laboratory service provides valuable insights into a capacitors performance under extreme conditions. By analyzing the results, we can

Determine Capacitor Suitability Identify whether a capacitor is suitable for use in high-temperature applications.

Identify Potential Failure Points Pinpoint areas where capacitors may be prone to failure due to excessive leakage current.

Develop Custom Solutions Collaborate with our clients to develop custom solutions that address specific capacitor performance issues.

QA Measuring Electrolytic Capacitor Leakage at High Temperatures

Frequently Asked Questions

Q What types of capacitors can be tested using this service?

A Our laboratory service is designed for use with electrolytic capacitors, including aluminum, tantalum, and ceramic types. We also test film and solid capacitors.

Q What are the benefits of measuring electrolytic capacitor leakage at high temperatures in a controlled laboratory environment?

A Our controlled environment ensures accurate results, which can be replicated and verified as needed. This is particularly important for businesses that require precise data to inform their product development and manufacturing processes.

Q How long does it take to complete the testing process?

A The length of time required to complete the testing process varies depending on the number of capacitors being tested and the complexity of the results analysis.

Q What kind of equipment is used for this service?

A Our laboratory employs state-of-the-art equipment, including high-temperature ovens and specialized measurement instruments, to accurately measure electrolytic capacitor leakage at high temperatures.

Conclusion

Measuring electrolytic capacitor leakage at high temperatures is an essential laboratory service that provides businesses with critical insights into the performance of their electronic components. By identifying potential issues early on, companies can minimize warranty claims, improve product reliability, increase efficiency, and ensure compliance with industry standards.

At Eurolab, we are committed to providing accurate and reliable results, ensuring our clients have the data they need to make informed decisions about their products. Our team of experts is dedicated to helping businesses optimize their electronic components and reduce the risk of product failure.

Contact us today to learn more about how our Measuring Electrolytic Capacitor Leakage at High Temperatures service can benefit your business.