Simulating Capacitor Leakage in Battery-Powered Devices

Simulating Capacitor Leakage in Battery-Powered Devices A Crucial Service for Businesses

In todays fast-paced and increasingly competitive business landscape, manufacturers of battery-powered devices must ensure that their products meet the highest standards of safety, reliability, and performance. One critical aspect of achieving these goals is simulating capacitor leakage in battery-powered devices a laboratory service offered by Eurolab. This specialized testing helps businesses identify potential issues related to capacitor degradation, reducing the risk of costly recalls, warranty claims, and damaged reputations.

What is Capacitor Leakage?

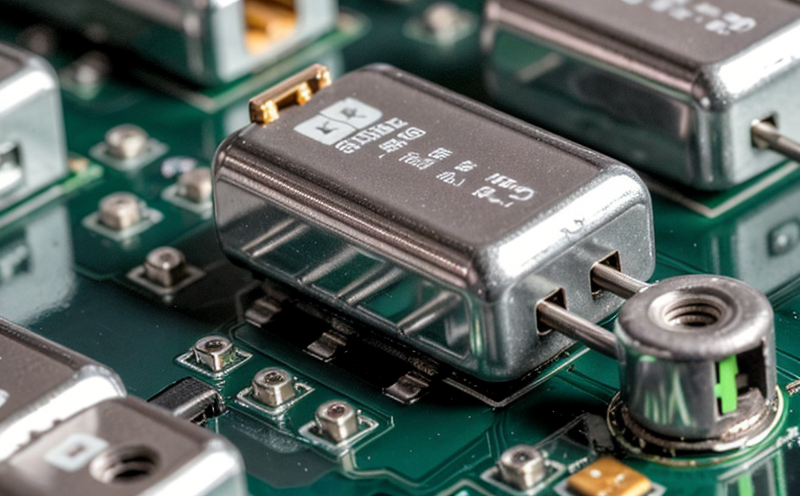

Capacitors are essential components in battery-powered devices, playing a crucial role in filtering, regulating, and stabilizing electrical signals. However, capacitors can degrade over time due to factors such as high temperatures, voltage stress, and chemical reactions. When capacitors leak, they can cause short circuits, leading to system failures, data loss, and even fires.

Why is Simulating Capacitor Leakage in Battery-Powered Devices Essential?

Simulating capacitor leakage in battery-powered devices enables manufacturers to

Predict Potential Failures By identifying capacitor degradation issues early on, businesses can take corrective actions to prevent costly product recalls and warranty claims.

Enhance Safety and Reliability Regular testing helps ensure that products meet stringent safety standards, reducing the risk of accidents, injuries, and fatalities associated with electrical malfunctions.

Optimize Product Design and Performance Simulating capacitor leakage enables manufacturers to fine-tune their products designs, improving efficiency, reducing energy consumption, and enhancing overall performance.

Reduce Warranty Claims and Returns By proactively addressing capacitor-related issues, businesses can minimize warranty claims, returns, and exchange costs.

Meet Regulatory Requirements Compliance with industry standards, such as UL (Underwriters Laboratories) and IEC (International Electrotechnical Commission), is crucial for manufacturers. Simulating capacitor leakage ensures that products meet these requirements.

Improve Brand Reputation and Customer Trust Companies that prioritize product safety and reliability can build trust with their customers, protecting their brand reputation and driving long-term loyalty.

Key Benefits of Eurolabs Laboratory Service

Eurolabs expert team provides a comprehensive laboratory service for simulating capacitor leakage in battery-powered devices. The benefits of choosing our service include

State-of-the-Art Equipment Our laboratory is equipped with the latest technology, ensuring accurate and reliable results.

Expert Analysis and Interpretation Our experienced technicians provide detailed analysis and interpretation of test data, enabling manufacturers to make informed decisions.

Rapid Turnaround Times We offer expedited testing services to meet tight project schedules and deadlines.

Customized Solutions Eurolabs team works closely with clients to develop tailored testing protocols, addressing specific business needs and requirements.

QA Section

Q What is the purpose of simulating capacitor leakage in battery-powered devices?

A The primary goal is to predict potential failures, enhance safety and reliability, optimize product design and performance, reduce warranty claims and returns, meet regulatory requirements, and improve brand reputation and customer trust.

Q How does Eurolabs laboratory service ensure accurate results?

A Our team uses state-of-the-art equipment and follows rigorous testing protocols to guarantee reliable and precise test data.

Q What types of battery-powered devices can be tested for capacitor leakage?

A Eurolabs laboratory service is applicable to a wide range of products, including smartphones, laptops, tablets, electric vehicles, renewable energy systems, and medical devices.

Q Can you provide examples of companies that have benefited from simulating capacitor leakage in their battery-powered devices?

A Yes, numerous manufacturers have successfully used our laboratory service to identify potential issues related to capacitor degradation. These businesses have experienced significant reductions in warranty claims, returns, and exchange costs, as well as improved product safety and reliability.

Q What is the typical turnaround time for testing and analysis?

A Eurolabs team strives to provide rapid turnaround times while maintaining accuracy and quality. We can accommodate expedited testing services to meet tight project schedules and deadlines.

Conclusion

Simulating capacitor leakage in battery-powered devices is a critical service that helps businesses ensure product safety, reliability, and performance. By partnering with Eurolab, manufacturers can predict potential failures, reduce warranty claims and returns, enhance brand reputation, and comply with industry standards. Our expert team provides state-of-the-art equipment, customized solutions, and rapid turnaround times to meet the unique needs of each client.

Invest in your businesss future by choosing Eurolabs laboratory service for simulating capacitor leakage in battery-powered devices. Contact us today to learn more about how our expertise can help you achieve success in the competitive market.