Testing Capacitor Leakage in Medical Device Circuits

Testing Capacitor Leakage in Medical Device Circuits Ensuring Safety and Reliability

In the rapidly evolving medical device industry, ensuring the safety and reliability of electronic components is a top priority for manufacturers. One crucial aspect of this process is testing capacitor leakage in medical device circuits. This laboratory service, offered by Eurolab, plays a vital role in preventing product recalls, reducing costs associated with rework, and ultimately safeguarding patients lives.

What is Testing Capacitor Leakage in Medical Device Circuits?

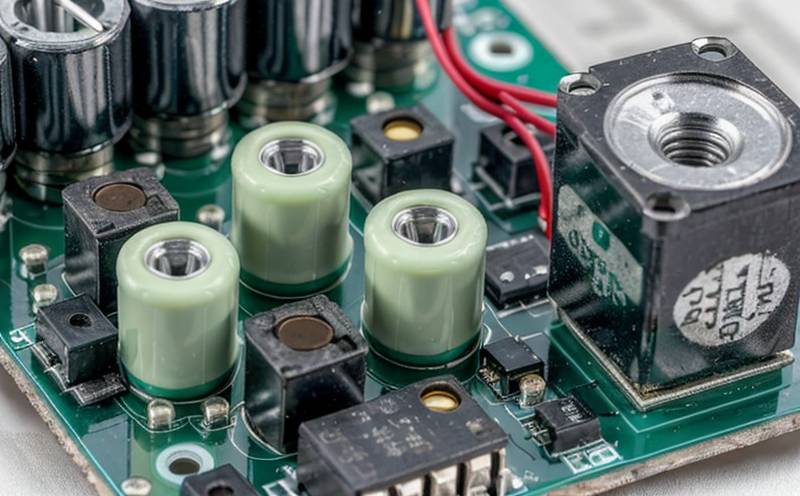

Capacitors are an essential component in electronic circuits, including those found in medical devices. They store electrical energy and help regulate the flow of current. However, over time, capacitors can develop leakage, which can lead to malfunction or even failure. In medical devices, this can have severe consequences, compromising patient safety and potentially leading to adverse events.

Eurolabs Testing Capacitor Leakage in Medical Device Circuits service is a specialized laboratory test designed to identify and measure capacitor leakage in electronic circuits. Our expert technicians use state-of-the-art equipment to detect even the slightest signs of leakage, providing valuable insights that inform design improvements and manufacturing optimizations.

Advantages of Using Eurolabs Testing Capacitor Leakage in Medical Device Circuits

Partnering with Eurolab for Testing Capacitor Leakage in Medical Device Circuits offers numerous benefits for medical device manufacturers. Some key advantages include

Enhanced Patient Safety By identifying capacitor leakage early on, manufacturers can prevent faulty products from reaching the market, reducing the risk of adverse events and ensuring patient safety.

Reduced Costs Detecting capacitor leakage during the design or production phase saves manufacturers time and money by avoiding costly rework or product recalls.

Improved Reliability Testing capacitor leakage helps identify potential failure points, enabling manufacturers to optimize their designs and improve overall circuit reliability.

Compliance with Regulations By conducting regular testing for capacitor leakage, medical device manufacturers can ensure compliance with regulatory requirements, such as those set by the FDA.

Increased Efficiency Eurolabs streamlined testing process reduces turnaround times, allowing manufacturers to get products to market faster while maintaining quality and safety standards.

Benefits of Testing Capacitor Leakage in Medical Device Circuits Key Points

Early Detection Identify capacitor leakage early on to prevent faulty products from reaching the market.

Design Optimization Use insights gained from testing to optimize designs and improve overall circuit reliability.

Reduced Wastage Minimize production waste by detecting issues during design or production phase.

Enhanced Customer Trust Demonstrate a commitment to safety and quality, building trust with customers and regulatory bodies.

QA Frequently Asked Questions

Q What is capacitor leakage?

A Capacitor leakage refers to the loss of electrical charge over time, which can lead to malfunction or failure in electronic circuits.

Q Why is Testing Capacitor Leakage in Medical Device Circuits essential for manufacturers?

A It ensures patient safety, reduces costs associated with rework and product recalls, improves reliability, and maintains regulatory compliance.

Q What types of medical devices require capacitor leakage testing?

A All medical devices that utilize electronic circuits, including implantable devices, diagnostic equipment, and life support systems.

Q How does Eurolabs Testing Capacitor Leakage in Medical Device Circuits service work?

A Our expert technicians use state-of-the-art equipment to detect even the slightest signs of leakage, providing valuable insights for design improvements and manufacturing optimizations.

Q What are the benefits of partnering with Eurolab for Testing Capacitor Leakage in Medical Device Circuits?

A Enhanced patient safety, reduced costs, improved reliability, compliance with regulations, and increased efficiency.

By choosing Eurolabs Testing Capacitor Leakage in Medical Device Circuits service, medical device manufacturers can ensure that their products meet the highest standards of quality, safety, and reliability. Our expertise and state-of-the-art equipment guarantee accurate results, providing valuable insights for design improvements and manufacturing optimizations.

Conclusion

In conclusion, testing capacitor leakage in medical device circuits is a critical aspect of ensuring patient safety and product reliability. Eurolabs specialized laboratory service provides manufacturers with the confidence to deliver high-quality products that meet regulatory requirements and customer expectations. By partnering with us, you can reduce costs associated with rework and product recalls, improve circuit reliability, and ultimately safeguard patients lives.

Take the First Step towards Ensuring Patient Safety and Reliability

Contact Eurolab today to learn more about our Testing Capacitor Leakage in Medical Device Circuits service and discover how we can support your business.