Testing for Capacitor Leakage Under Voltage Stress

Testing for Capacitor Leakage Under Voltage Stress A Crucial Service for Businesses

In todays fast-paced and competitive business landscape, ensuring the reliability and efficiency of electronic components is paramount. Among these crucial components are capacitors, which play a vital role in various applications, from electronics to automotive systems. However, capacitors can be prone to defects, particularly capacitor leakage under voltage stress, which can lead to catastrophic failures and costly downtime. Thats where Testing for Capacitor Leakage Under Voltage Stress comes into play a specialized laboratory service provided by Eurolab that helps businesses identify potential issues before they become major problems.

What is Testing for Capacitor Leakage Under Voltage Stress?

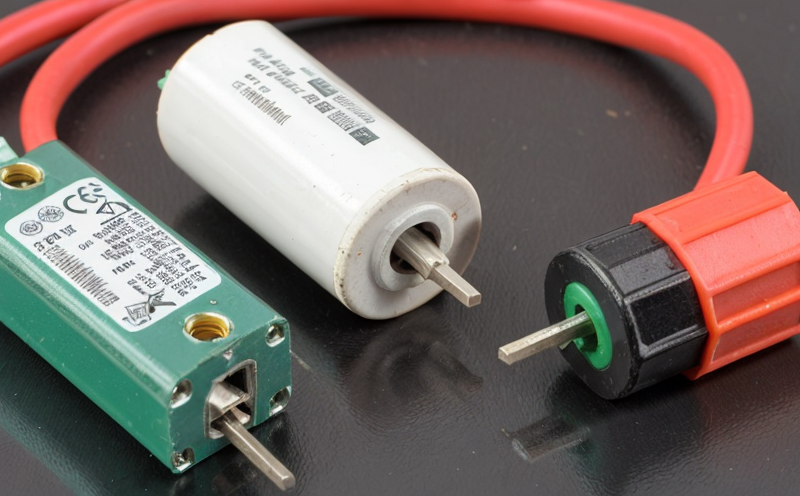

Capacitors are used extensively in electronic circuits to filter, regulate, and store energy. However, when exposed to high voltages or abnormal operating conditions, capacitors can experience leakage a phenomenon where the dielectric material between the capacitors plates breaks down, allowing electric current to flow through the device. This leakage can lead to reduced capacitance values, increased heat generation, and ultimately, catastrophic failure of the component.

Testing for Capacitor Leakage Under Voltage Stress is a specialized laboratory service designed to evaluate capacitors under controlled voltage stress conditions. Eurolabs expert technicians use sophisticated equipment to subject capacitors to various voltage levels, simulating real-world operating conditions. This ensures that capacitors are thoroughly tested and evaluated for any signs of leakage or other defects.

Why is Testing for Capacitor Leakage Under Voltage Stress Essential?

The consequences of capacitor failure can be severe, resulting in costly downtime, reduced productivity, and compromised product reliability. By identifying potential issues early on through Testing for Capacitor Leakage Under Voltage Stress, businesses can

Reduce Downtime Early detection of capacitor defects allows for swift replacement or repair, minimizing the risk of equipment failure and reducing overall maintenance costs.

Improve Product Reliability Thorough testing ensures that capacitors meet the required specifications, enhancing product reliability and reducing the likelihood of field failures.

Increase Efficiency By identifying potential issues early on, businesses can optimize production processes, reduce waste, and improve overall efficiency.

Comply with Industry Regulations Many industries require regular testing and inspection to ensure compliance with regulatory standards. Eurolabs Testing for Capacitor Leakage Under Voltage Stress helps businesses meet these requirements and avoid costly fines or penalties.

Benefits of Using Eurolabs Testing for Capacitor Leakage Under Voltage Stress

At Eurolab, we pride ourselves on providing a comprehensive range of laboratory services designed to meet the unique needs of our clients. Here are just some of the benefits of using our Testing for Capacitor Leakage Under Voltage Stress service

Accurate and Reliable Results Our expert technicians use state-of-the-art equipment to ensure accurate and reliable test results.

Rapid Turnaround Times We understand that time is money, which is why we offer fast turnaround times without compromising on quality or accuracy.

Expert Analysis Our experienced analysts provide detailed reports and recommendations for improvement, helping businesses make informed decisions about capacitor replacement or repair.

Compliance with Industry Standards Eurolabs testing services are designed to meet the latest industry standards, including IPC, MIL-STD, and IEC.

QA Frequently Asked Questions About Testing for Capacitor Leakage Under Voltage Stress

What types of capacitors can be tested?

Our laboratory service is applicable to all types of capacitors, including film, ceramic, electrolytic, and tantalum.

How long does the testing process take?

Test times vary depending on the type and number of capacitors being evaluated, but most tests are completed within 24-48 hours.

What are the benefits of testing for capacitor leakage under voltage stress?

Early detection of defects allows for swift replacement or repair, reducing downtime and maintenance costs while improving product reliability and efficiency.

Can I send my own equipment to be tested?

Yes, we accept samples from various sources, including manufacturing facilities, distribution centers, and end-users.

How do I ensure compliance with industry regulations?

Our testing services are designed to meet the latest industry standards, ensuring that your products meet regulatory requirements.

Conclusion

In todays competitive business landscape, reliability and efficiency are crucial components of any successful operation. Testing for Capacitor Leakage Under Voltage Stress is an essential service that helps businesses identify potential issues before they become major problems. By using Eurolabs comprehensive testing services, you can

Reduce downtime and maintenance costs

Improve product reliability and efficiency

Comply with industry regulations

Ensure compliance with industry standards

Dont risk the performance and longevity of your products choose Eurolab for Testing for Capacitor Leakage Under Voltage Stress. Contact us today to learn more about our laboratory services and how we can help you achieve your business goals.