Assessing hardness in 3D printed metallic components

Assessing Hardness in 3D Printed Metallic Components Unlock the Secrets to Ensuring Quality and Reliability

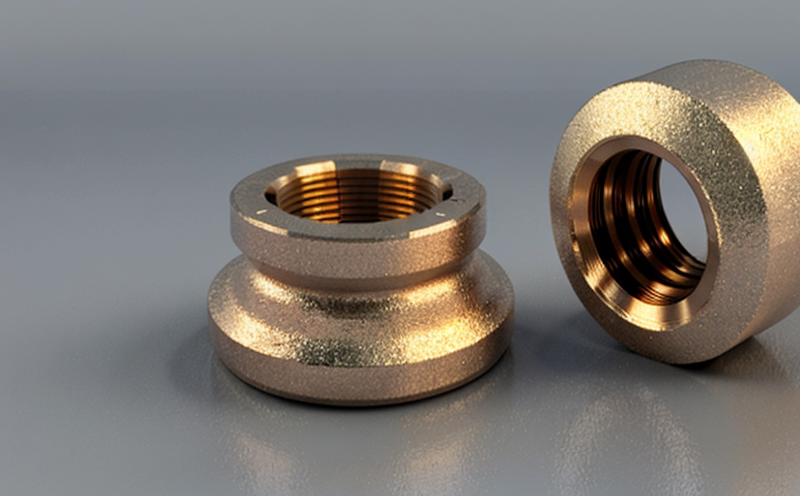

In todays fast-paced manufacturing landscape, businesses are increasingly relying on 3D printing technology to produce complex metallic components with unprecedented speed and precision. However, one critical aspect that often gets overlooked is the assessment of hardness in these printed parts. Hardness testing is a vital step in ensuring the quality and reliability of 3D printed metallic components, which can significantly impact their performance and lifespan.

At Eurolab, our team of experts understands the importance of assessing hardness in 3D printed metallic components and offers a comprehensive laboratory service to support your manufacturing needs. In this article, we will delve into the significance of hardness testing, its benefits, and why it is essential for businesses looking to optimize their production processes.

What is Assessing Hardness in 3D Printed Metallic Components?

Hardness testing involves measuring the resistance of a material to deformation or abrasion. In the context of 3D printed metallic components, assessing hardness is crucial because it helps determine the materials ability to withstand various environmental and operational stresses. Hardness can affect a components performance in several ways, including its durability, wear resistance, and fatigue life.

The Advantages of Assessing Hardness in 3D Printed Metallic Components

Improved Quality Control By assessing hardness, you can ensure that your 3D printed metallic components meet the required specifications, reducing the risk of defects and failures.

Increased Reliability Hardness testing helps identify potential material weaknesses, allowing for targeted improvements to enhance the overall reliability of your products.

Reduced Costs By detecting issues early on, you can avoid costly rework or replacement, minimizing waste and optimizing production processes.

Enhanced Product Performance Assessing hardness enables you to optimize material selection, processing conditions, and design parameters, resulting in improved product performance and lifespan.

Compliance with Industry Standards Our laboratory service ensures that your 3D printed metallic components meet the necessary standards for hardness, guaranteeing compliance with industry regulations.

How Does Eurolabs Assessing Hardness Service Work?

At Eurolab, our team of experts utilizes state-of-the-art equipment and techniques to assess the hardness of your 3D printed metallic components. Our laboratory service includes

Material Selection We work closely with you to select the most suitable material for your application.

Sample Preparation Our technicians carefully prepare the samples for testing, ensuring accuracy and precision.

Hardness Testing We employ various methods, including Rockwell hardness testing, Vickers hardness testing, and Brinell hardness testing, to determine the materials hardness.

Data Analysis Our team interprets the test results, providing you with a comprehensive report detailing the materials hardness properties.

QA Frequently Asked Questions About Assessing Hardness in 3D Printed Metallic Components

Q Why is assessing hardness so important for 3D printed metallic components?

A Assessing hardness ensures that your products meet industry standards and can withstand various environmental and operational stresses, reducing the risk of defects and failures.

Q What methods do you use to assess hardness at Eurolab?

A We employ Rockwell hardness testing, Vickers hardness testing, and Brinell hardness testing, depending on the materials properties and your specific requirements.

Q Can I get a quick turnaround time for my samples?

A Yes, our team works efficiently to ensure timely results, typically within 24-48 hours.

Q How do you handle sensitive or proprietary information related to my products?

A We maintain strict confidentiality and adhere to industry standards for data protection, ensuring the secure handling of your sensitive information.

Conclusion

Assessing hardness in 3D printed metallic components is a critical step in ensuring quality and reliability. By partnering with Eurolabs laboratory service, you can ensure that your products meet the required specifications, reduce costs, and improve performance. Dont compromise on the integrity of your products choose Eurolab for your assessing hardness needs.

Get Started Today

To learn more about our assessing hardness services or to discuss your specific requirements, please contact us through our website. Our team is committed to supporting your manufacturing needs with expertise, precision, and a passion for delivering exceptional results.