Knoop hardness testing for thin materials

Unlocking the Secrets of Thin Materials The Power of Knoop Hardness Testing with Eurolab

In todays fast-paced manufacturing world, materials play a vital role in determining the success or failure of products and industries alike. For businesses operating in various sectors such as aerospace, automotive, electronics, and more, understanding the mechanical properties of thin materials is crucial for optimizing performance, safety, and cost-effectiveness. One laboratory service that stands out as an essential tool in this endeavor is Knoop hardness testing for thin materials offered by Eurolab.

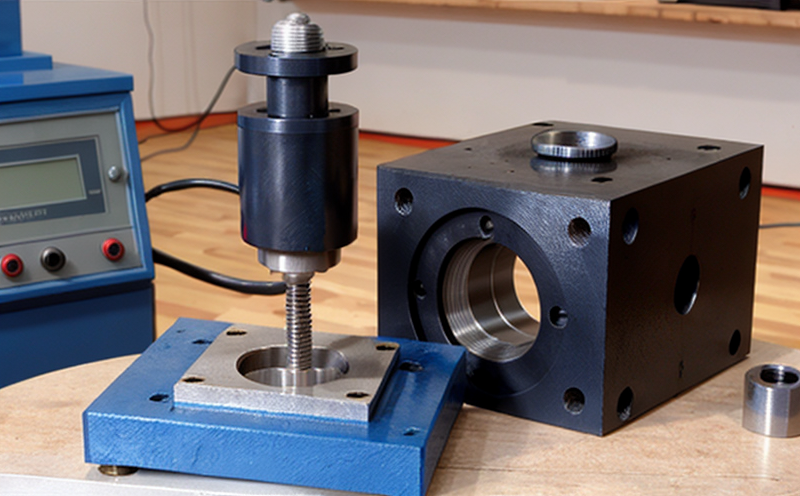

Knoop hardness testing, a widely accepted standard technique, measures the indentation hardness of materials using a pyramidal indenter with a precise tip radius. For thin materials, such as foils, sheets, or coatings, accurate and reliable measurement of hardness becomes increasingly challenging due to their fragile nature. This is where Eurolabs Knoop hardness testing for thin materials comes into play, providing businesses with the necessary insights to make informed decisions about material selection, processing, and application.

The Advantages of Using Knoop Hardness Testing for Thin Materials

Eurolabs Knoop hardness testing service offers a plethora of benefits for businesses working with thin materials. Here are some key advantages in bullet point form

Accurate Measurements Our state-of-the-art equipment ensures accurate measurements, even on the thinnest of materials, providing reliable data for decision-making.

High Precision With our skilled technicians and precise instruments, we guarantee high precision results that are essential for quality control and material selection.

Comprehensive Reports Detailed reports include not only the Knoop hardness values but also microindentation impressions, allowing for a comprehensive understanding of material properties.

Quick Turnaround Time Eurolabs efficient testing process ensures minimal downtime, enabling businesses to respond quickly to changing market demands or production requirements.

Expert Interpretation Our team of experienced engineers and scientists provide expert interpretation of results, ensuring that businesses receive actionable insights to improve their operations.

Compliance with Industry Standards Our testing methods adhere to international standards (e.g., ASTM E384), giving businesses confidence in the accuracy and reliability of our findings.

Why Knoop Hardness Testing for Thin Materials Matters

In industries where material thickness is critical, such as

Aerospace Thin materials are used extensively in aircraft components. Accurate hardness measurement ensures their strength and durability.

Automotive Lightweight yet strong materials are necessary for automotive applications, making Knoop hardness testing a vital quality control measure.

Electronics Thin films and coatings play a crucial role in electronic devices. Our testing service helps ensure these materials meet the required standards.

A Comprehensive QA Section

We understand that some questions may arise regarding our Knoop hardness testing service. Here are answers to some frequently asked questions

Q What is the minimum thickness of material that can be tested using this method?

A Eurolabs equipment allows for accurate measurements on materials as thin as 10 micrometers.

Q How does Knoop hardness testing differ from other indentation methods, such as Vickers or Rockwell?

A The main difference lies in the indenter geometry and the calculated hardness value. Knoop hardness is more suitable for brittle materials and has a smaller impression diameter compared to Vickers or Rockwell tests.

Q What types of thin materials can be tested using this service?

A Our testing capabilities include metals, ceramics, polymers, composites, and thin films/coatings.

Q Can you provide calibration certificates for the equipment used in Knoop hardness testing?

A Yes, we issue calibration certificates for each test, ensuring compliance with industry standards and regulations.

Conclusion

In conclusion, Eurolabs Knoop hardness testing service is an indispensable tool for businesses working with thin materials. Our state-of-the-art equipment, expert technicians, and comprehensive reporting ensure accurate measurements that inform decision-making. Whether your business operates in aerospace, automotive, electronics, or other sectors where material thickness is critical, our Knoop hardness testing service provides the necessary insights to optimize performance, safety, and cost-effectiveness.

Choose Eurolab for reliable Knoop hardness testing results that empower your business to succeed in todays competitive market.