Indentation tests for surface hardness evaluation

Unlocking Material Secrets Understanding Indentation Tests for Surface Hardness Evaluation

As a business owner in the manufacturing sector, you understand the importance of ensuring that your products meet the required standards of quality and performance. One crucial aspect of product evaluation is surface hardness testing, which determines how resistant materials are to wear and abrasion. This critical parameter has a significant impact on the overall lifespan and durability of your products.

In this article, we will delve into the world of indentation tests for surface hardness evaluation, a laboratory service provided by Eurolab. We will explore its significance, advantages, and benefits in detail, making it easier for you to understand why this service is essential for your business.

What are Indentation Tests for Surface Hardness Evaluation?

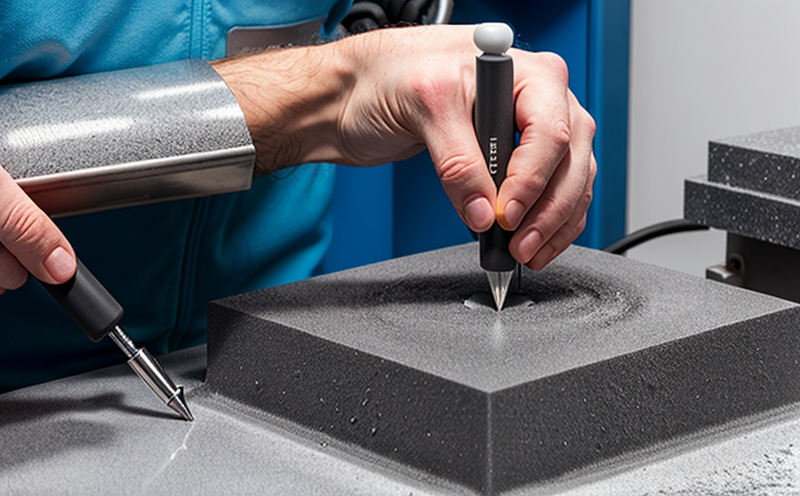

Indentation tests, also known as indentation hardness testing, involve pressing a hard indenter into the surface of a material under controlled conditions. This test measures the resistance of the material to plastic deformation and the resulting residual impression left by the indenter. The most commonly used indentation test is the Rockwell hardness test (HRC), which provides a quantitative measure of the materials surface hardness.

Why Indentation Tests for Surface Hardness Evaluation are Essential

Businesses across various industries rely on accurate surface hardness evaluation to ensure that their products meet regulatory requirements, withstand environmental conditions, and maintain performance over time. Here are some compelling reasons why indentation tests for surface hardness evaluation are crucial

Ensures Material Compliance Surface hardness testing ensures that materials comply with industry standards and regulations, reducing the risk of product failure and costly rework.

Predicts Wear and Abrasion Resistance By measuring surface hardness, businesses can accurately predict wear and abrasion resistance, allowing for informed material selection and process optimization.

Improves Product Lifespan Surface hardness evaluation helps identify potential weaknesses in materials, enabling businesses to implement targeted maintenance strategies and extend product lifespan.

Enhances Quality Control Accurate surface hardness testing supports quality control initiatives, ensuring that products meet customer expectations and industry standards.

Advantages of Using Indentation Tests for Surface Hardness Evaluation

Indentation tests offer numerous benefits over other surface hardness evaluation methods. Here are some key advantages

High Accuracy Indentation tests provide precise measurements, eliminating the subjectivity associated with manual testing methods.

Reliability Automated indentation testing ensures consistent results, reducing the risk of human error and increasing confidence in test data.

Scalability This method can be applied to a wide range of materials, from metals to polymers, making it an indispensable tool for businesses across various industries.

Cost-Effective Indentation tests are often more cost-effective than destructive testing methods, which can be time-consuming and expensive.

QA Frequently Asked Questions about Indentation Tests

Q What materials can be tested using indentation tests?

A A wide range of materials can be evaluated, including metals, polymers, ceramics, and composites.

Q How accurate are indentation test results?

A Results are highly accurate, with a high degree of reproducibility and reliability.

Q Can indentation tests be used for destructive testing purposes?

A Yes, indentation tests can be used to determine the hardness of materials in a controlled, non-destructive manner or to evaluate the surface properties after destructive testing.

Q What are the typical applications of indentation test results?

A Results are used to ensure material compliance with industry standards and regulations, predict wear and abrasion resistance, improve product lifespan, and enhance quality control initiatives.

By understanding the significance and advantages of indentation tests for surface hardness evaluation, businesses can make informed decisions about their products and processes. Eurolabs comprehensive laboratory services provide accurate and reliable results, ensuring that your materials meet regulatory requirements and withstand environmental conditions.

If youre interested in learning more about how Eurolabs laboratory services can support your business needs, we invite you to explore our website and discover the benefits of working with a trusted partner like us.