Microhardness testing for small samples

Unlocking Material Secrets Microhardness Testing for Small Samples

In the world of materials science and engineering, understanding the properties of materials is crucial for businesses to ensure product quality, reliability, and performance. One essential property that plays a significant role in determining material behavior is microhardness. Eurolab offers a specialized laboratory service Microhardness testing for small samples designed to provide businesses with precise data on their materials microhardness. This article delves into the world of microhardness testing, highlighting its importance and benefits, as well as addressing common questions.

What is Microhardness Testing for Small Samples?

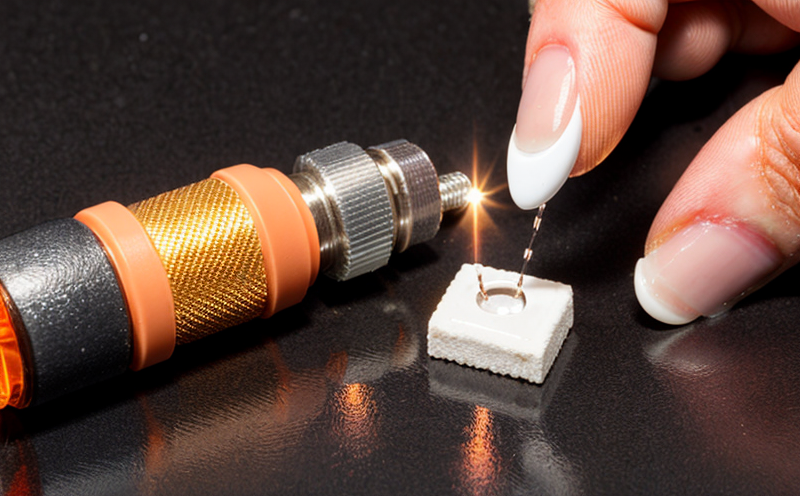

Microhardness testing involves measuring the hardness of a material at a very small scale using specialized equipment known as a Vickers hardness tester or a Knoop hardness tester. The test applies a specific load to a diamond indenter on the surface of the sample, creating an indentation that is then measured. This measurement is proportional to the microhardness of the material.

Microhardness testing for small samples is particularly beneficial in industries where materials are produced in small quantities or have unique geometries that make it difficult to obtain large sample sizes. It provides precise information about the materials properties, which can be critical in determining its suitability for a particular application.

Why is Microhardness Testing Essential for Businesses?

The advantages of microhardness testing are multifaceted and essential for businesses operating in various sectors

Ensures Material Quality By measuring the microhardness of small samples, manufacturers can assess the materials properties accurately. This information helps identify whether the material meets the required standards or needs further processing to achieve the desired quality.

Optimizes Production Processes Microhardness testing enables businesses to refine their production processes by identifying areas where materials may be too hard or too soft for a particular application. This information can help streamline production, reduce waste, and improve efficiency.

Enhances Product Performance Understanding microhardness is crucial in determining how a material will perform under various conditions. For example, in the aerospace industry, microhardness affects the wear resistance of materials subjected to high friction.

Facilitates Material Selection Microhardness testing helps businesses choose the most suitable materials for their products based on specific requirements. This informed decision-making leads to better product performance and reduced material waste.

Key Benefits of Microhardness Testing

Some of the key benefits of microhardness testing for small samples include

Accurate Material Characterization Microhardness testing provides precise data on a materials properties, enabling businesses to make informed decisions about its application.

Increased Efficiency By understanding the microhardness of materials, businesses can optimize production processes and reduce waste.

Improved Product Performance Knowing how a material will behave under various conditions helps manufacturers design products with enhanced performance characteristics.

Enhanced Quality Control Microhardness testing supports quality control by identifying areas where materials may not meet required standards.

Frequently Asked Questions

What is the minimum sample size for microhardness testing?

Our laboratory equipment can handle samples as small as a few millimeters in diameter.

How long does it take to perform microhardness testing?

Testing time varies depending on the sample size and type of material, but typically takes around 30 minutes to several hours.

What types of materials can be tested using microhardness testing?

Our laboratory can test a wide range of materials, including metals, ceramics, polymers, and composites.

Conclusion

Microhardness testing for small samples is an indispensable tool in the toolbox of businesses operating in various industries. By providing precise data on material properties, this service enables manufacturers to make informed decisions about production processes, material selection, and product performance. Eurolabs specialized laboratory services ensure accurate microhardness testing results, helping businesses optimize their operations, improve product quality, and enhance customer satisfaction.