Effects of heat treatment on metal hardness

The Science Behind Heat Treatment Unlocking the Full Potential of Metal Hardness

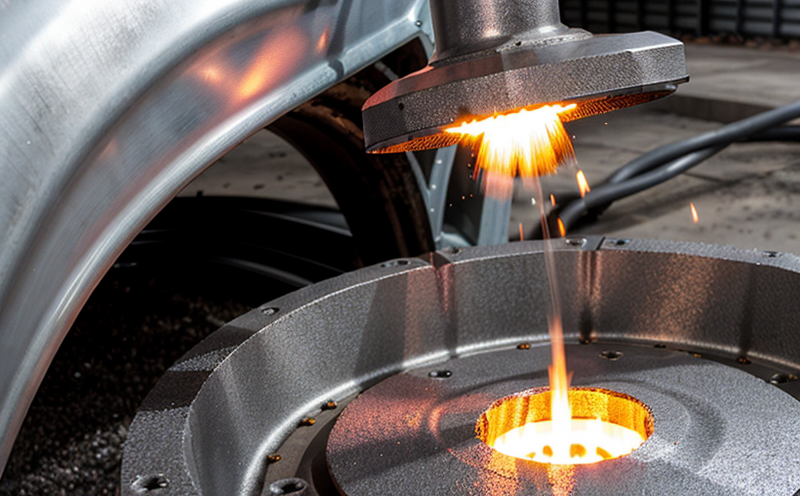

In the world of metallurgy, heat treatment is a crucial process that has been used for centuries to manipulate the properties of metals and alloys. By carefully controlling temperature and time, metal manufacturers can transform raw materials into high-performance products with enhanced strength, durability, and resistance to wear and tear. One of the most significant benefits of heat treatment is its ability to alter metal hardness, making it a vital laboratory service for businesses across various industries.

At Eurolab, our team of expert metallurgists is dedicated to providing accurate and reliable results for Effects of heat treatment on metal hardness testing. In this article, we will delve into the intricacies of heat treatment, exploring its advantages, benefits, and applications. Whether youre a manufacturer seeking to optimize your production process or an engineer looking to improve product performance, understanding the effects of heat treatment on metal hardness is essential for success.

What is Heat Treatment?

Heat treatment involves the controlled heating and cooling of metals to modify their physical and mechanical properties. This process can be applied to various types of materials, including ferrous and non-ferrous alloys, as well as ceramics and glass. The primary objective of heat treatment is to achieve a specific combination of strength, toughness, ductility, and hardness.

Why is Heat Treatment Important?

Heat treatment plays a critical role in the production of high-performance metals, particularly those used in aerospace, automotive, and industrial applications. By carefully controlling temperature and time, manufacturers can

Improve surface finish Heat treatment allows for the removal of imperfections, resulting in a smoother, more even surface finish.

Enhance strength Heat-treated metals exhibit increased tensile strength, making them ideal for high-stress applications.

Increase wear resistance By altering the microstructure of metals, heat treatment can improve their resistance to corrosion and abrasion.

Optimize machining Heat-treated metals are easier to machine and shape, reducing production time and costs.

The Effects of Heat Treatment on Metal Hardness

Heat treatment has a profound impact on metal hardness, which is measured using the Rockwell or Vickers hardness test. By subjecting metals to various heat treatment cycles, manufacturers can achieve specific levels of hardness, from soft (annealed) to very hard (tempered).

Types of Heat Treatment

Annealing Heating to a specific temperature to reduce internal stresses and make metal more workable.

Normalizing Heating above the critical temperature to achieve uniform microstructure and then cooling in still air.

Hardening Heating to a high temperature, followed by rapid quenching (cooling) to maximize hardness.

Tempering Heating to a lower temperature after hardening to reduce brittleness while maintaining some hardness.

Advantages of Heat Treatment

The benefits of heat treatment on metal hardness are numerous and can be summarized as follows

Improved machining efficiency Heat-treated metals are easier to cut, drill, and shape.

Enhanced durability Heat-treated metals exhibit increased resistance to wear, corrosion, and fatigue.

Increased product lifespan By optimizing metal properties, manufacturers can extend the life of their products.

Cost savings Reduced material waste and improved production efficiency lead to cost savings.

Common Applications of Effects of Heat Treatment on Metal Hardness

Heat treatment is a vital process in various industries, including

Aerospace High-strength alloys for aircraft and spacecraft components.

Automotive Engine blocks, gears, and other critical components require optimized hardness levels.

Industrial Heavy machinery, tools, and equipment benefit from heat-treated metals with improved strength and durability.

Medical Implantable devices, surgical instruments, and other medical equipment demand high-quality materials.

QA Frequently Asked Questions About Effects of Heat Treatment on Metal Hardness

Q What is the purpose of heat treatment?

A To modify metal properties by altering its microstructure and achieving specific levels of hardness.

Q How does heat treatment affect metal hardness?

A Heat treatment can increase, decrease, or maintain metal hardness, depending on the temperature and time applied.

Q Can any type of metal be heat-treated?

A No, certain metals (e.g., titanium) are not suitable for heat treatment due to their unique properties.

Q How do I determine the optimal heat treatment cycle for my specific application?

A Consult with a qualified metallurgist or perform experiments under controlled conditions.

Conclusion

The effects of heat treatment on metal hardness are a critical consideration in various industries, from aerospace and automotive to industrial and medical. By understanding how heat treatment can alter metal properties, manufacturers can unlock the full potential of their products and improve performance, efficiency, and lifespan. At Eurolab, our team of expert metallurgists is committed to providing accurate and reliable results for Effects of heat treatment on metal hardness testing. Whether youre seeking to optimize your production process or simply want to learn more about this fascinating field, we invite you to explore the science behind heat treatment.

Why Choose Eurolab?

Expertise Our team has extensive experience in metallurgy and heat treatment.

State-of-the-art equipment We utilize advanced instruments for accurate testing and analysis.

Reliable results Trust our lab-certified reports for confident decision-making.

Stay ahead of the competition by selecting a trusted laboratory partner. Contact us today to learn more about our Effects of heat treatment on metal hardness services.