Innovations in hardness testing techniques

Innovations in Hardness Testing Techniques Revolutionizing Material Evaluation for Businesses

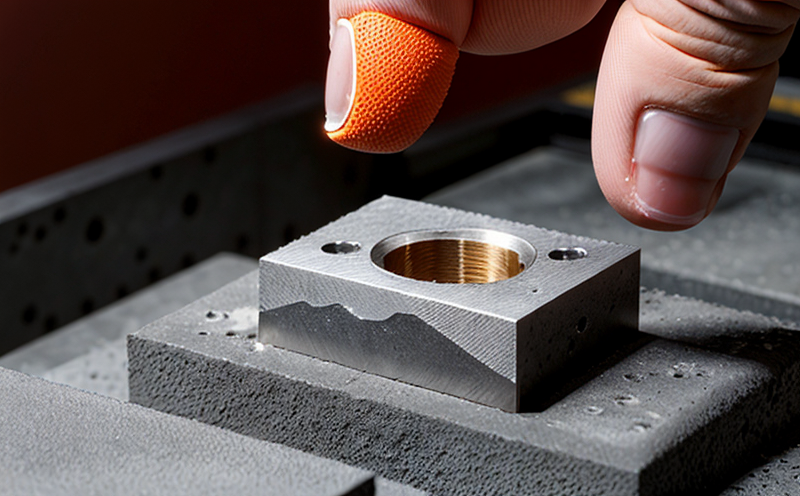

Hardness testing is a crucial aspect of material evaluation, enabling businesses to assess the mechanical properties of materials with precision and accuracy. However, conventional hardness testing techniques have limitations, including subjective results, limited sample size, and lengthy testing times. In recent years, innovations in hardness testing techniques have emerged, transforming the industry with enhanced reliability, efficiency, and accuracy.

At Eurolab, we pride ourselves on providing cutting-edge laboratory services that cater to the evolving needs of industries worldwide. Our team of experts utilizes state-of-the-art equipment and methodologies to ensure unparalleled results. This article delves into the innovations in hardness testing techniques, highlighting their benefits, applications, and significance for businesses.

The Evolution of Hardness Testing Techniques

Traditionally, hardness testing has relied on manual methods such as scratch testing or impact indentation. These approaches are plagued by subjective interpretations, limited sample sizes, and time-consuming procedures. Modern advancements have transformed the landscape, introducing automated and advanced techniques that minimize human error and maximize precision.

Some notable innovations in hardness testing techniques include

High-Performance Automated Hardness Testing (HPAHT) This technique utilizes advanced instruments to conduct precise indentation tests, providing reliable data with minimal operator intervention.

Nanoindentation A cutting-edge method that applies forces at the nanoscale to evaluate material properties, offering unparalleled insights into surface topography and mechanical behavior.

X-Ray Computed Tomography (XCT) Hardness Testing This non-destructive technique utilizes X-ray imaging to analyze material internal structures, enabling accurate hardness assessments without sample destruction.

Advantages of Innovations in Hardness Testing Techniques

The incorporation of innovative hardness testing techniques has revolutionized the industry, offering numerous benefits for businesses. Some key advantages include

Key Benefits

Improved Accuracy and Reliability Advanced techniques reduce human error and provide precise results, ensuring informed decision-making.

Enhanced Efficiency Automated instruments minimize manual intervention, accelerating testing times and increasing throughput.

Increased Sample Size Modern methods allow for larger sample sizes, reducing the need for statistical inference and providing more comprehensive data.

Non-Destructive Testing Techniques like XCT enable non-invasive material evaluation, preserving samples and eliminating unnecessary waste.

Applications of Innovations in Hardness Testing Techniques

The benefits of innovative hardness testing techniques are multifaceted, with applications spanning various industries

Industry-Specific Benefits

Aerospace and Defense Advanced hardness testing ensures precise control over critical mechanical properties, guaranteeing optimal performance in extreme environments.

Automotive Improved accuracy and efficiency enable faster development cycles, allowing for more innovative vehicle designs and reduced production costs.

Medical Devices Enhanced hardness testing techniques ensure reliable material evaluation, ensuring the safety and efficacy of medical implants and equipment.

Frequently Asked Questions

What is the primary advantage of modern hardness testing techniques?

Improved accuracy and reliability due to reduced human error and automated instruments.

How do innovations in hardness testing techniques benefit industries worldwide?

By providing precise control over critical mechanical properties, enabling faster development cycles, and ensuring material safety and efficacy.

Are advanced hardness testing methods non-destructive?

Yes, techniques like XCT enable non-invasive material evaluation, preserving samples and eliminating unnecessary waste.

Conclusion

The innovations in hardness testing techniques have transformed the industry with enhanced reliability, efficiency, and accuracy. At Eurolab, we recognize the significance of these advancements and remain committed to providing cutting-edge laboratory services that cater to the evolving needs of businesses worldwide. By embracing innovative hardness testing methods, industries can unlock unparalleled insights into material properties, drive innovation, and stay ahead of the competition.

Stay ahead of the curve with Eurolabs expert analysis and state-of-the-art equipment.