Assessing the resistance of aerospace materials to UV-induced cracks and fractures

Assessing the Resistance of Aerospace Materials to UV-induced Cracks and Fractures Ensuring the Integrity of Your Aircraft Components

As the aerospace industry continues to push the boundaries of innovation and advancement, the demand for high-performance materials has never been greater. However, with this increased performance comes an inherent risk the potential for damage from environmental factors such as ultraviolet (UV) radiation. UV-induced cracks and fractures can have devastating consequences for aircraft components, compromising safety, reducing lifespan, and increasing maintenance costs.

Thats where Eurolab comes in a leading provider of laboratory services dedicated to helping businesses like yours ensure the integrity of their aerospace materials. Our team of experts offers a comprehensive assessment service designed to evaluate the resistance of your materials to UV-induced cracks and fractures. In this article, well delve into the importance of this service, its key benefits, and answer frequently asked questions.

The Importance of Assessing the Resistance of Aerospace Materials to UV-induced Cracks and Fractures

Aerospace materials are exposed to a wide range of environmental stresses during their lifespan, including temperature fluctuations, moisture, and radiation. While some materials can withstand these stresses with minimal damage, others may be more susceptible to degradation.

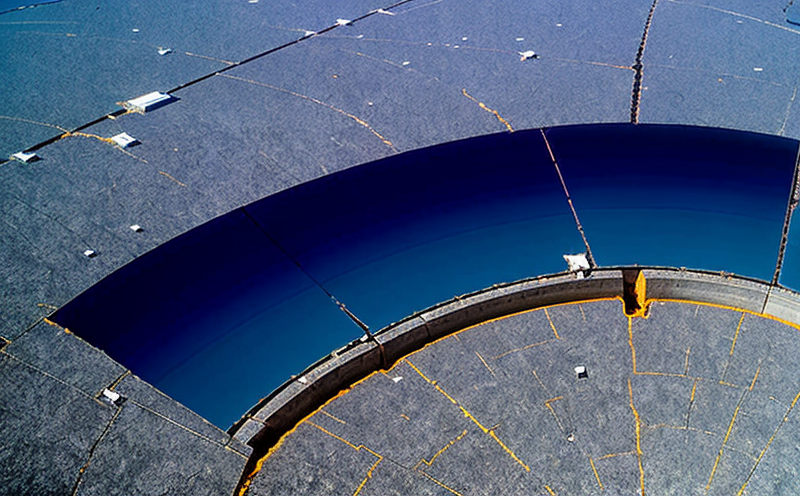

UV radiation, in particular, poses a significant threat to aerospace materials. Exposure to UV light can cause materials to degrade through photochemical reactions, leading to cracks and fractures that compromise their structural integrity. This is particularly concerning for aircraft components such as composite materials, which are increasingly used in modern aircraft design.

The consequences of ignoring the effects of UV radiation on aerospace materials can be severe

Reduced component lifespan

Increased maintenance costs

Compromised safety standards

Potential loss of certification

Advantages of Using Eurolabs Assessing the Resistance of Aerospace Materials to UV-induced Cracks and Fractures Service

Eurolabs assessment service is designed to help businesses like yours mitigate these risks by evaluating the resistance of your materials to UV-induced cracks and fractures. The benefits of using our service are numerous

Improved Material Selection Our expert analysis helps you choose the most suitable materials for your specific application, reducing the risk of material failure.

Extended Component Lifespan By identifying potential weaknesses in your materials, we can help you extend their lifespan, saving you time and money on maintenance and replacement.

Enhanced Safety Standards Our assessments ensure that your components meet or exceed regulatory requirements, maintaining the highest standards of safety.

Reduced Maintenance Costs By detecting potential issues early on, we can help you avoid costly repairs and replacements.

Increased Component Performance Our expert analysis helps optimize material performance, leading to improved aircraft efficiency and reduced fuel consumption.

Key Benefits of Eurolabs Assessing the Resistance of Aerospace Materials to UV-induced Cracks and Fractures Service

Comprehensive Analysis Our team conducts a thorough examination of your materials, evaluating their resistance to UV-induced cracks and fractures.

Customized Solutions We work closely with you to develop tailored recommendations for material selection, testing, and validation.

Expertise in Aerospace Materials Our experts have extensive knowledge of aerospace materials, ensuring that our assessments are accurate and reliable.

State-of-the-Art Facilities Our laboratory is equipped with the latest technology and equipment, enabling us to conduct thorough and precise analysis.

Frequently Asked Questions (FAQs)

Q What types of aerospace materials can be assessed using Eurolabs service?

A We assess a wide range of aerospace materials, including composite materials, polymers, metals, and ceramics.

Q How do you evaluate the resistance of aerospace materials to UV-induced cracks and fractures?

A Our team conducts a comprehensive analysis using various techniques, including microscopy, spectroscopy, and mechanical testing.

Q What are the benefits of assessing the resistance of aerospace materials to UV-induced cracks and fractures?

A By identifying potential weaknesses in your materials, we can help you improve material selection, extend component lifespan, enhance safety standards, reduce maintenance costs, and increase component performance.

Q How long does the assessment process take?

A The duration of our assessments varies depending on the complexity of the project. However, we typically complete our assessments within 2-4 weeks.

Q Can I obtain certification or compliance reports for my materials?

A Yes, our team can provide certification and compliance reports for your materials, ensuring that they meet regulatory requirements.

Conclusion

Assessing the resistance of aerospace materials to UV-induced cracks and fractures is a critical step in ensuring the integrity of aircraft components. Eurolabs laboratory service provides businesses like yours with a comprehensive evaluation of your materials, identifying potential weaknesses and recommending tailored solutions for material selection, testing, and validation.

By working with us, you can

Improve material selection

Extend component lifespan

Enhance safety standards

Reduce maintenance costs

Increase component performance

Dont let the risks associated with UV radiation compromise your aircraft components. Contact Eurolab today to schedule an assessment and take the first step towards ensuring the integrity of your aerospace materials.

Related Services

Material Characterization Comprehensive analysis of material properties, including mechanical, thermal, and electrical behavior.

Component Testing Evaluation of component performance under various environmental conditions, including temperature, humidity, and vibration.

Failure Analysis Expert investigation into material failures, identifying root causes and recommending corrective actions.

Eurolab Your Partner in Aerospace Material Assessment

At Eurolab, we understand the importance of accurate and reliable testing in ensuring the safety and efficiency of aircraft components. Our team of experts is dedicated to providing you with comprehensive assessments that meet or exceed regulatory requirements.

Trust us to help you navigate the complex world of aerospace materials, ensuring that your components meet the highest standards of performance, reliability, and safety.