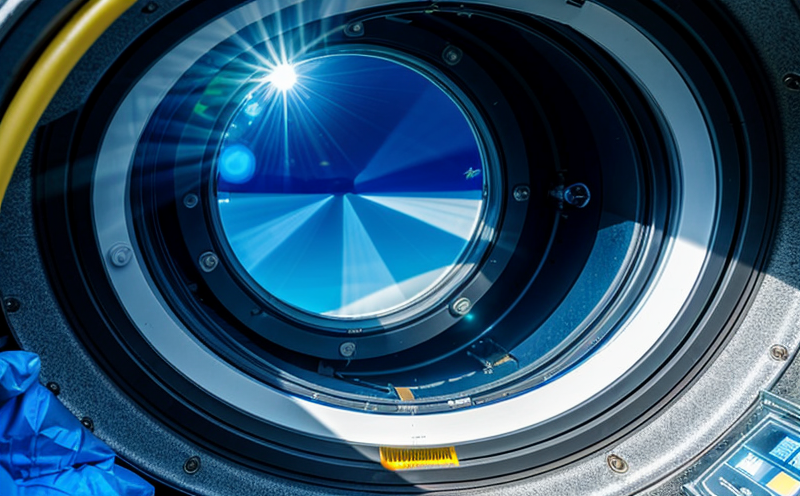

UV exposure testing for the protection of sensitive materials and sensors in aerospace systems

The Importance of UV Exposure Testing for Sensitive Materials and Sensors in Aerospace Systems Why Eurolabs Expertise is Unparalleled

In the world of aerospace engineering, the development of cutting-edge systems and technologies relies on the rigorous testing and validation of materials and sensors to ensure their reliability and performance in extreme environments. One critical aspect of this process is UV exposure testing for the protection of sensitive materials and sensors, which is essential for safeguarding against the corrosive effects of ultraviolet radiation.

As the aerospace industry continues to push boundaries in terms of speed, efficiency, and innovation, the need for specialized laboratory services that cater to its unique demands has never been more pressing. Thats where Eurolab comes in a leading provider of expert testing solutions tailored specifically to the needs of the aerospace sector. Our state-of-the-art UV exposure testing facilities are designed to simulate real-world conditions, subjecting materials and sensors to intense ultraviolet radiation that mimics the effects of space environments.

What is UV Exposure Testing?

UV exposure testing involves exposing materials and sensors to controlled doses of ultraviolet radiation, typically in a vacuum or inert atmosphere. This process allows for the simulation of real-world environmental conditions, enabling researchers to assess the materials durability, resistance, and degradation under prolonged UV exposure. By doing so, they can identify areas for improvement and develop strategies to mitigate the effects of UV radiation on sensitive components.

Advantages of Using UV Exposure Testing

The benefits of using UV exposure testing in aerospace applications are multifaceted

Assessment of Material Degradation Identify potential weaknesses in materials and sensors that may be vulnerable to UV-induced degradation, ensuring their performance is not compromised in harsh space environments.

Validation of Protective Coatings Test the efficacy of coatings and surface treatments designed to shield sensitive components from UV radiation, guaranteeing their effectiveness against environmental stressors.

Optimization of Design Parameters Refine material selection and design parameters to minimize exposure time, reduce energy consumption, or enhance overall efficiency in aerospace systems.

Enhanced Reliability and Performance Ensure the reliability and longevity of critical components by simulating real-world conditions, reducing the risk of premature failure due to UV-induced degradation.

Key Benefits for Businesses

Our expert UV exposure testing services offer numerous advantages to businesses operating within the aerospace sector

Reduced Development Time and Costs Minimize the time and resources required to develop new materials and sensors through rigorous testing and validation.

Improved System Reliability Enhance overall system performance by identifying areas for improvement and optimizing design parameters.

Competitive Advantage Stay ahead of industry trends by leveraging our cutting-edge laboratory facilities and expert knowledge.

Comprehensive Testing Services

Eurolabs UV exposure testing services encompass a range of specialized tests tailored to the unique needs of aerospace materials and sensors

UV-Induced Degradation (UID) Testing Assess material degradation under controlled UV radiation conditions, simulating real-world environmental effects.

Protective Coating Evaluation Validate the effectiveness of coatings and surface treatments against UV-induced damage.

Material Selection and Optimization Refine material selection based on performance, durability, and other critical parameters.

Expert Consultation and Support

At Eurolab, we understand that aerospace engineering is a complex field requiring tailored solutions. Our team of experts provides comprehensive support throughout the testing process

Customized Testing Programs Design bespoke testing programs to meet specific requirements and objectives.

Collaborative Research and Development Work closely with clients to develop innovative solutions for sensitive materials and sensors.

Frequently Asked Questions (FAQs)

Q What types of materials can be tested using UV exposure testing?

A Materials used in aerospace applications, such as polymers, composites, and ceramics, are commonly tested under UV radiation conditions.

Q How does Eurolabs expertise compare to that of other laboratory services providers?

A Our team has extensive experience working with aerospace clients, providing tailored solutions to meet the unique demands of the industry.

Q Can you provide data on the benefits of using UV exposure testing for sensitive materials and sensors in aerospace systems?

A Yes, our clients have reported significant reductions in development time and costs, as well as improved system reliability through rigorous testing and validation.

Conclusion

In conclusion, Eurolabs expert UV exposure testing services are an indispensable asset for businesses operating within the aerospace sector. By simulating real-world environmental conditions, we enable researchers to assess material degradation, validate protective coatings, optimize design parameters, and enhance overall system performance. Dont compromise on the integrity of your critical components trust our laboratory expertise to ensure their reliability and longevity in harsh space environments.

Get in Touch with Us

To learn more about Eurolabs comprehensive testing services or discuss your specific requirements with one of our experts, please contact us through our website or via email.