UV exposure testing for aerospace materials to assess degradation and discoloration

The Unyielding Sun How UV Exposure Testing Ensures the Durability of Aerospace Materials

In the realm of aerospace engineering, materials play a crucial role in withstanding the unforgiving conditions of space and extreme temperatures. Among these conditions, ultraviolet (UV) radiation poses one of the most significant challenges to material durability. Prolonged exposure to UV light can lead to degradation, discoloration, and ultimately, the failure of critical components. To mitigate this risk, Eurolab offers advanced UV exposure testing services specifically designed for aerospace materials.

The Importance of Assessing Degradation and Discoloration

UV exposure testing is an indispensable tool in evaluating the resilience of aerospace materials against environmental stressors. The harsh conditions encountered during space missions can be replicated in a laboratory setting using controlled UV radiation, allowing manufacturers to assess material degradation and discoloration prior to deployment.

This proactive approach not only ensures compliance with industry regulations but also prevents costly delays and recalls associated with failed components. By investing in UV exposure testing, aerospace companies can guarantee the reliability and performance of their materials, ultimately safeguarding the success of their missions.

Advantages of Using UV Exposure Testing for Aerospace Materials

Our comprehensive range of services offers numerous benefits to aerospace manufacturers

Predictive Maintenance Identify potential issues before they occur, reducing downtime and extending product lifespan.

Enhanced Durability Assess material degradation under controlled conditions, ensuring optimal performance in extreme environments.

Compliance with Industry Regulations Meet the stringent standards set by regulatory bodies, such as NASA or the European Space Agency (ESA).

Cost Savings Avoid costly delays and recalls associated with failed components.

Improved Material Selection Evaluate materials based on their UV resistance, enabling informed decisions for future projects.

Key Benefits of Our Services

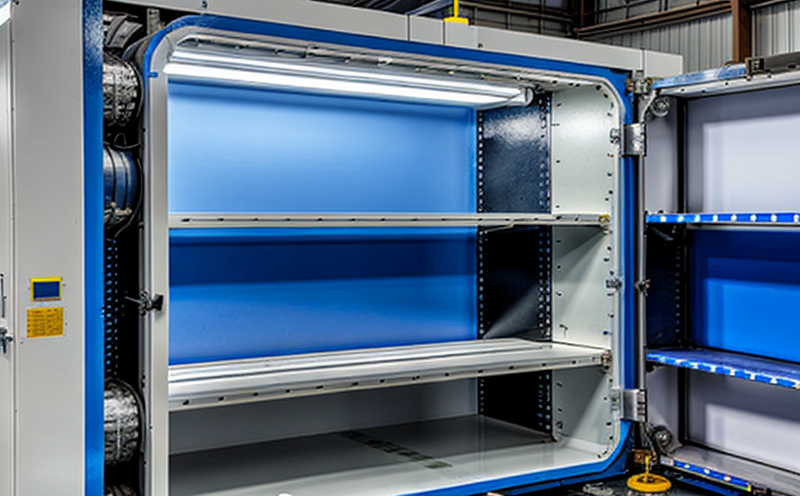

Our state-of-the-art laboratory facilities are equipped to handle a wide range of aerospace materials, including

Polymers Assess the impact of UV radiation on polymer-based materials, ensuring optimal performance in extreme environments.

Metals Evaluate metal alloys for resistance to corrosion and degradation under UV exposure.

Composites Test composite materials for their ability to withstand UV radiation without compromising structural integrity.

Frequently Asked Questions

Q What is the purpose of UV exposure testing?

A UV exposure testing simulates the effects of prolonged sunlight on aerospace materials, allowing manufacturers to assess degradation and discoloration prior to deployment.

Q How does Eurolabs service ensure compliance with industry regulations?

A Our team works closely with clients to develop customized testing protocols that meet specific regulatory requirements, ensuring seamless integration into existing quality control procedures.

Q What types of materials can be tested using UV exposure testing?

A Our laboratory facilities are equipped to handle a wide range of aerospace materials, including polymers, metals, and composites.

Q Can I request a custom testing protocol for my specific needs?

A Yes. Our team will work closely with you to develop a tailored testing plan that meets your unique requirements and objectives.

By investing in UV exposure testing services from Eurolab, aerospace manufacturers can ensure the reliability and performance of their materials, safeguarding the success of their missions and upholding the highest standards of quality control.