Testing the impact of UV radiation on the lifecycle of aerospace components and materials

The Unyielding Sun Testing the Impact of UV Radiation on Aerospace Components and Materials

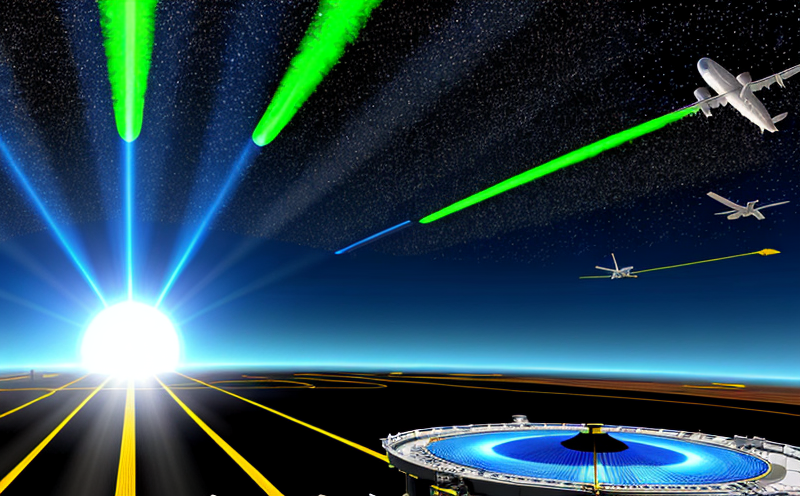

In the unforgiving expanse of space, aerospace components and materials face a constant battle against the harsh conditions of radiation exposure. Among these, ultraviolet (UV) radiation stands as one of the most significant threats to the lifecycle of these critical components. Prolonged exposure to UV radiation can lead to degradation, damage, and even failure, compromising the safety and performance of aircraft, spacecraft, and satellites.

At Eurolab, we specialize in providing a vital laboratory service that helps businesses mitigate this risk Testing the Impact of UV Radiation on the Lifecycle of Aerospace Components and Materials. This cutting-edge service is designed to simulate real-world radiation exposure conditions, allowing our clients to assess the resilience of their components and materials under extreme conditions.

The Importance of Testing UV Radiations Impact

In the aerospace industry, understanding the effects of UV radiation is crucial for several reasons

Ensuring Safety Components damaged by UV radiation can compromise the structural integrity and safety of aircraft, spacecraft, or satellites. Regular testing helps identify potential weaknesses before they become catastrophic.

Maintaining Performance UV damage can lead to reduced efficiency, power loss, and increased maintenance costs. Testing ensures that components operate within specified parameters, extending their lifespan and reducing downtime.

Compliance with Regulations Many space agencies and regulatory bodies require manufacturers to demonstrate the durability of their components under UV radiation conditions. Eurolabs testing services help ensure compliance with these standards.

The Benefits of Using Eurolabs Testing Services

Our laboratory service provides numerous benefits, including

Accurate Predictions By simulating real-world radiation exposure, we provide accurate predictions about component lifespan and performance.

Improved Reliability Regular testing helps identify potential weaknesses, enabling our clients to take corrective action before failures occur.

Cost Savings Identifying and addressing issues early on reduces maintenance costs, extends component lifespan, and minimizes downtime.

Enhanced Reputation Demonstrating compliance with regulatory standards enhances the reputation of manufacturers and suppliers.

How Our Testing Services Work

Our laboratory employs advanced equipment to simulate a range of UV radiation conditions. The testing process involves

Sample Preparation We carefully prepare samples according to our clients specifications.

UV Radiation Simulation Our state-of-the-art equipment simulates real-world UV radiation exposure conditions, including intensity and duration.

Monitoring and Analysis We continuously monitor the samples during testing, analyzing data to determine the effects of UV radiation.

QA Frequently Asked Questions

Q1 What types of aerospace components and materials can be tested?

A1 Our laboratory services a wide range of materials and components, including polymers, composites, metals, and electronics.

Q2 How do I prepare my samples for testing?

A2 We require that clients provide clear specifications for sample preparation, including any specific requirements or protocols.

Q3 What types of UV radiation conditions can be simulated?

A3 Our equipment allows us to simulate a range of UV radiation conditions, from low to high intensities and durations.

Q4 How long does the testing process typically take?

A4 The duration of testing varies depending on the specific requirements of each project. However, our expert team works efficiently to minimize delays.

Conclusion

In todays fast-paced aerospace industry, ensuring the reliability and performance of components and materials under extreme conditions is vital. Eurolabs Testing the Impact of UV Radiation on the Lifecycle of Aerospace Components and Materials service provides a critical advantage for manufacturers and suppliers. By leveraging our expertise and state-of-the-art equipment, our clients can

Enhance safety

Maintain performance

Comply with regulations

Dont let the unyielding sun compromise your components lifespan. Choose Eurolabs laboratory services to ensure their reliability and performance in even the most extreme conditions.