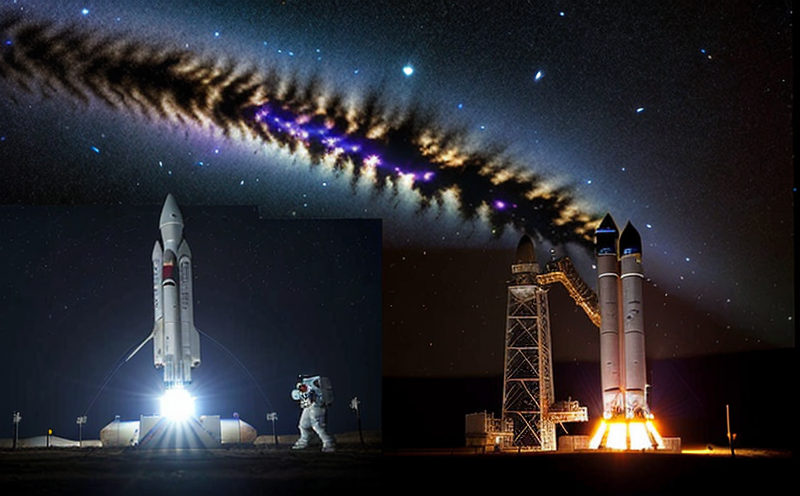

UV exposure testing for space vehicles and materials exposed to the vacuum of space

The Crucial Role of UV Exposure Testing in Space Exploration Ensuring the Reliability and Durability of Space Vehicles and Materials

As the demand for space exploration continues to grow, businesses involved in this sector must ensure that their products and materials can withstand the harsh conditions of space travel. One critical aspect of space vehicle development is testing the effects of ultraviolet (UV) radiation on various materials exposed to the vacuum of space. Eurolab offers a comprehensive laboratory service for UV exposure testing, providing vital insights into the performance and reliability of space vehicles and their components.

Why UV Exposure Testing Matters

The vacuum of space poses unique challenges to space vehicles and materials. The absence of atmospheric protection exposes them to extreme temperatures, radiation, and other environmental stressors that can compromise their integrity. Among these factors, UV radiation is particularly hazardous due to its ability to cause degradation and damage to materials at unprecedented rates.

UV exposure testing for space vehicles and materials exposed to the vacuum of space is essential because it simulates real-world conditions, enabling businesses to

Identify material weaknesses Understand how various materials react to prolonged exposure to UV radiation, allowing for informed decisions on component selection.

Optimize design and manufacturing processes Make data-driven improvements to ensure that components can withstand extreme temperatures and radiation levels.

Enhance product reliability Ensure that space vehicles and their components are designed and manufactured with durability in mind.

The Benefits of EUROLABs UV Exposure Testing Services

Our expert team at Eurolab has developed a state-of-the-art facility for simulating the effects of UV radiation on materials. Our comprehensive testing services offer numerous benefits to businesses, including

Comprehensive testing protocols Our laboratory is equipped with advanced equipment that replicates the conditions found in space, providing precise and accurate results.

Multi-material testing capabilities We test a wide range of materials commonly used in space vehicle construction, ensuring our clients can make informed decisions on material selection.

Customized testing programs Our team works closely with clients to develop tailored testing protocols that meet specific project requirements.

Rapid turnaround times Our efficient laboratory processes enable us to deliver results quickly, allowing businesses to stay ahead of the competition.

Compliance with industry standards We ensure our testing methods and reporting adhere to relevant regulations and guidelines, providing our clients with peace of mind.

Key Benefits of Using EUROLABs UV Exposure Testing Services

Some of the key advantages of using Eurolabs services include

Cost savings Identify material weaknesses and optimize design processes before production, reducing the likelihood of costly re-designs or product recalls.

Time efficiency Our comprehensive testing protocols save time by providing actionable data that can inform design decisions.

Reduced risk Ensure that space vehicles and components are reliable and durable, minimizing the risk of equipment failure or system crashes.

Frequently Asked Questions

Q What types of materials can be tested using your UV exposure testing service?

A Our laboratory is equipped to test a wide range of materials commonly used in space vehicle construction, including polymers, metals, ceramics, and composite materials.

Q How do you simulate the conditions found in space?

A Our facility is equipped with advanced equipment that replicates the temperature fluctuations, radiation levels, and vacuum conditions found in space.

Q Can I customize my testing program to meet specific project requirements?

A Yes. Our team works closely with clients to develop tailored testing protocols that meet their unique needs.

Q What kind of data can I expect from your UV exposure testing service?

A Our comprehensive reports provide detailed information on material degradation, including changes in color, texture, and mechanical properties.

Conclusion

The harsh conditions of space travel pose significant challenges to space vehicles and materials. Eurolabs UV exposure testing services provide a critical solution for businesses looking to ensure the reliability and durability of their products. By leveraging our comprehensive laboratory capabilities, businesses can make informed decisions on material selection, optimize design processes, and reduce costs associated with product development.

Dont compromise on product performance trust Eurolab to help you navigate the complex world of space vehicle testing. Contact us today to learn more about our UV exposure testing services.