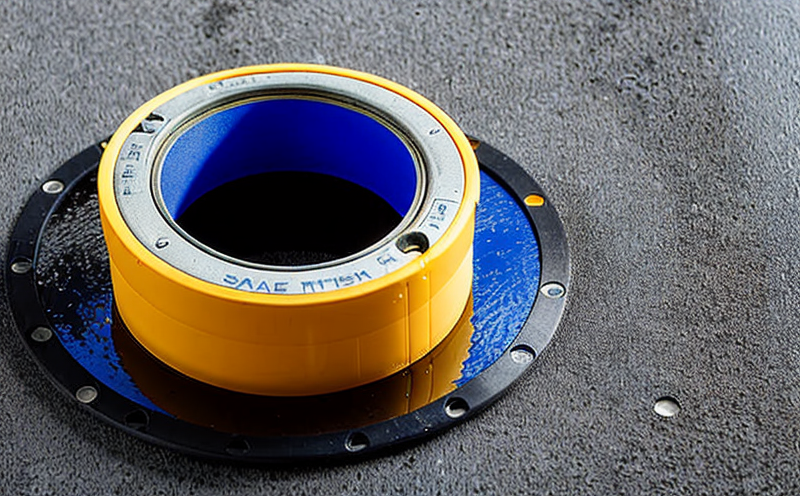

Testing the UV resistance of aerospace seals and gaskets to prevent leaks and damage

Unlocking Reliability Testing the UV Resistance of Aerospace Seals and Gaskets with Eurolab

In the high-stakes world of aerospace engineering, reliability is paramount. A single malfunction can have catastrophic consequences, from costly delays to devastating safety risks. When it comes to ensuring the integrity of aircraft systems, one critical aspect often overlooked is the testing of ultraviolet (UV) resistance in seals and gaskets.

UV exposure is a harsh reality for components exposed to sunlight or artificial lighting during flight, ground operations, or storage. Over time, UV radiation can degrade materials, leading to increased leakage rates, decreased performance, and even catastrophic failure. Eurolab understands the importance of safeguarding against these risks, which is why we offer Testing the UV resistance of aerospace seals and gaskets as a specialized laboratory service.

The Importance of Testing UV Resistance in Aerospace Seals and Gaskets

In todays competitive aerospace landscape, manufacturers must adhere to stringent regulations and industry standards. Ensuring that all components meet or exceed these requirements is crucial for maintaining certification, reputation, and public trust. Our testing services help businesses guarantee the reliability and durability of their products.

Advantages of Testing UV Resistance with Eurolab

Our specialized laboratory offers a comprehensive range of benefits, including

Prevention of Leaks and Damage By identifying potential weaknesses in seals and gaskets before they cause damage, our testing services prevent costly repairs, delays, and reputational harm.

Enhanced Reliability Our expert analysis ensures that components meet or exceed industry standards for UV resistance, reducing the likelihood of system failures and ensuring the safety of passengers and crew.

Increased Efficiency By identifying areas for improvement in advance, manufacturers can optimize their designs and streamline production processes, leading to reduced costs and improved productivity.

Compliance with Industry Regulations Our testing services help businesses meet or exceed industry standards, such as those set by AS9100D (Rev D), AS9115 (Rev B), and other relevant regulations.

Benefits of Testing UV Resistance in Aerospace Seals and Gaskets

Reduced Maintenance Costs By identifying potential issues before they arise, our testing services help businesses avoid costly maintenance procedures, such as repairs or replacements.

Improved Safety Records Our analysis helps ensure that components meet or exceed industry standards for UV resistance, reducing the risk of system failures and improving overall safety records.

Enhanced Customer Trust Manufacturers who prioritize reliability and durability through rigorous testing can boost their reputation and customer trust, driving long-term growth and success.

Our Expertise in Testing the UV Resistance of Aerospace Seals and Gaskets

At Eurolab, our team of experienced engineers and technicians is dedicated to providing expert analysis and recommendations. Our state-of-the-art facilities feature cutting-edge equipment for simulating real-world UV exposure conditions. We work closely with clients to develop customized testing plans that meet their specific needs.

Frequently Asked Questions (FAQs)

Q What types of materials can be tested?

A Our laboratory is equipped to test a wide range of materials commonly used in aerospace seals and gaskets, including elastomers, fluoropolymers, silicone-based compounds, and more.

Q How do you simulate real-world UV exposure conditions?

A Our team uses advanced equipment to mimic the effects of UV radiation on materials, including solar simulators and xenon lamps that accurately replicate sunlight and other environmental factors.

Q What kind of data can I expect from your testing services?

A We provide comprehensive reports detailing test results, material characteristics, and recommendations for improving performance or addressing weaknesses.

Q Can you help me develop a customized testing plan?

A Absolutely! Our team works closely with clients to create tailored plans that meet their specific needs and address potential risks associated with UV exposure.

Q How long does the testing process typically take?

A The duration of our testing services depends on various factors, including material type, test complexity, and client requirements. However, we strive to complete most projects within 2-6 weeks.

Conclusion

In an industry where reliability is paramount, Eurolabs Testing the UV resistance of aerospace seals and gaskets service is a vital component in ensuring the safety, efficiency, and performance of aircraft systems. By partnering with us, manufacturers can rest assured that their products meet or exceed industry standards for durability and reliability.

Dont let UV exposure compromise your businesss reputation. Trust Eurolab to provide expert analysis and recommendations that safeguard against leaks, damage, and system failures. Contact us today to learn more about our comprehensive testing services and take the first step towards unlocking the full potential of your aerospace products.