Influence of cooling rate on metal microstructure

The Crucial Role of Cooling Rate in Shaping Metal Microstructure A Laboratory Service Provided by Eurolab

In the world of metallurgy and materials science, the influence of cooling rate on metal microstructure is a critical factor that can make all the difference between a materials success and failure. Whether youre a manufacturer, researcher, or engineer, understanding how different cooling rates impact the microstructure of metals is essential for producing high-quality products with desired properties.

At Eurolab, our team of experts offers a comprehensive laboratory service to help businesses like yours optimize their metal production processes by analyzing the effects of cooling rate on metal microstructure. In this article, well delve into the significance of influence of cooling rate on metal microstructure, its benefits, and how Eurolabs laboratory services can support your business.

What is Influence of Cooling Rate on Metal Microstructure?

Influence of cooling rate on metal microstructure refers to the changes that occur in a metals crystal structure when it cools down from high temperatures. As metals cool, their atoms arrange themselves into a lattice structure, and this arrangement affects the materials physical and mechanical properties.

Cooling rate is a critical factor influencing the formation of the microstructure, as rapid cooling can lead to the development of undesirable microstructural features such as

Inclusions

Porosity

Grain growth

On the other hand, slow cooling allows for more controlled grain growth, leading to improved material properties. Understanding how different cooling rates impact metal microstructure is crucial for tailoring materials to specific applications.

The Importance of Influence of Cooling Rate on Metal Microstructure

Influence of cooling rate on metal microstructure has far-reaching implications for various industries, including

Manufacturing By controlling the cooling rate, manufacturers can produce metals with tailored properties, such as increased strength, improved corrosion resistance, or enhanced ductility.

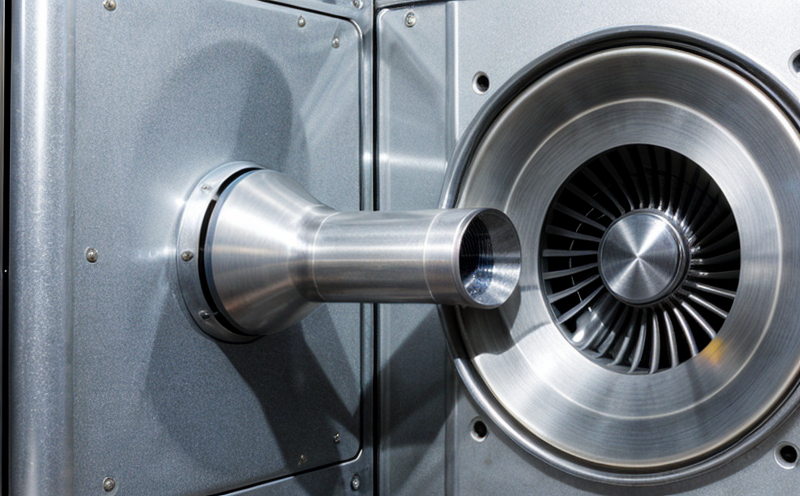

Aerospace High-performance materials are critical in aerospace applications. Understanding how to control cooling rates helps engineers design and manufacture components that meet stringent requirements for weight reduction, high-temperature resistance, and durability.

Automotive Cooling rate can significantly impact the performance of automotive parts, such as engine components, gears, and bearings.

Advantages of Using Influence of Cooling Rate on Metal Microstructure

Our laboratory service at Eurolab helps businesses optimize their metal production processes by analyzing the effects of cooling rate on metal microstructure. Some key benefits include

Improved material properties By controlling the cooling rate, you can produce materials with tailored mechanical, thermal, and electrical properties.

Reduced defects Understanding how to control cooling rates minimizes the occurrence of inclusions, porosity, and other undesirable features that can compromise material integrity.

Increased efficiency Optimized metal production processes enable faster production cycles, reduced waste, and lower energy consumption.

Key Benefits of Eurolabs Laboratory Service

Here are some key benefits of using our laboratory service

Tailored cooling rate optimization

Our experts analyze the effects of different cooling rates on your specific material

We provide recommendations for optimized cooling rates to achieve desired microstructural features

Material property enhancement

By controlling cooling rates, we help improve material properties such as strength, toughness, and corrosion resistance

You can ensure consistent performance in various applications

Reduced defects and waste

Our laboratory services help minimize the occurrence of inclusions, porosity, and other defects that compromise material integrity

We support your efforts to reduce waste and optimize production processes

QA Section

What types of materials can Eurolab analyze?

We work with a wide range of metallic materials, including steels, aluminum alloys, copper, titanium, and more.

How do you determine the optimal cooling rate for my material?

Our team uses advanced characterization techniques, such as scanning electron microscopy (SEM), transmission electron microscopy (TEM), and X-ray diffraction (XRD) to analyze your materials microstructure. We then recommend optimized cooling rates based on our findings.

Can I get a customized laboratory service package tailored to my business needs?

Yes! Our experts will work closely with you to develop a comprehensive laboratory service package that addresses your specific requirements and goals.

What kind of data can I expect from Eurolabs laboratory services?

We provide detailed reports, including microstructural analysis, material property evaluation, and recommendations for optimized cooling rates. We also offer ongoing support and consultation to ensure you achieve the desired results.

Conclusion

Influence of cooling rate on metal microstructure is a critical factor in determining material properties and performance. By understanding how different cooling rates impact your specific material, you can optimize production processes, reduce defects, and improve overall efficiency.

At Eurolab, were committed to helping businesses like yours succeed by providing expert laboratory services that unlock the full potential of their materials. Contact us today to learn more about our Influence of Cooling Rate on Metal Microstructure service and take your business to the next level!