Microstructural analysis for failure analysis

Unlocking the Secrets of Material Failure The Power of Microstructural Analysis for Failure Analysis

In todays fast-paced manufacturing world, product failure can be a costly and devastating experience for businesses. Whether its due to material defects, manufacturing errors, or improper use, understanding the root cause of a components failure is crucial for minimizing downtime, reducing costs, and ensuring consumer safety. This is where Microstructural analysis for failure analysis comes into play a cutting-edge laboratory service provided by Eurolab that helps businesses like yours identify the underlying causes of material failure.

What is Microstructural Analysis for Failure Analysis?

Microstructural analysis involves examining the internal structure and composition of materials to determine their properties, behavior, and potential weaknesses. In the context of failure analysis, this means analyzing the microstructure of a failed component or material to identify any defects, deformations, or anomalies that contributed to its failure. By understanding the underlying causes of failure, businesses can take corrective actions to prevent future occurrences, ensuring the integrity and reliability of their products.

Why is Microstructural Analysis for Failure Analysis Essential for Businesses?

In an industry where even a single product failure can have far-reaching consequences, investing in microstructural analysis for failure analysis is a strategic business decision. Here are some compelling reasons why

Advantages of Using Microstructural Analysis for Failure Analysis

Prevents Recurrence By identifying the root causes of material failure, businesses can implement targeted corrective actions to prevent future occurrences.

Reduces Costs Minimizing downtime and rework by understanding the underlying causes of failure saves businesses time, money, and resources.

Ensures Product Safety Accurate diagnosis of material defects helps ensure that products meet regulatory requirements and are safe for consumer use.

Improves Quality Control Microstructural analysis provides valuable insights into material properties and behavior, enabling businesses to refine their quality control processes and improve product reliability.

Fosters Innovation Understanding the microstructure of materials can inspire new product designs, manufacturing techniques, and materials development, driving innovation and competitiveness.

How Does Eurolabs Microstructural Analysis for Failure Analysis Work?

At Eurolab, our expert team employs state-of-the-art equipment and techniques to conduct thorough microstructural analysis. Our comprehensive process includes

Sampling Careful selection and preparation of representative samples from the failed component or material.

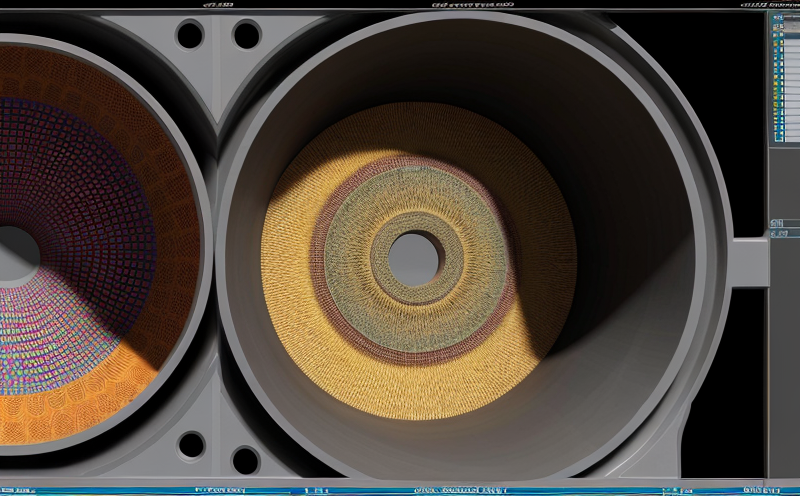

Microscopy High-resolution microscopy to examine the microstructure of the sample, including grain size, texture, and defects.

Chemical Analysis Advanced techniques such as X-ray fluorescence (XRF) or scanning electron microscopy-energy-dispersive spectroscopy (SEM-EDS) to determine elemental composition.

Computational Modeling Utilization of specialized software to simulate material behavior under various conditions.

Frequently Asked Questions

Weve addressed some common questions about microstructural analysis for failure analysis

Q What types of materials can be analyzed?

A Eurolabs expertise extends to a wide range of materials, including metals, alloys, ceramics, polymers, and composites.

Q How long does the analysis process typically take?

A The duration of the analysis varies depending on the complexity of the case, but our team strives to provide prompt results while maintaining high standards of quality and accuracy.

Q Can I trust the confidentiality of my data?

A At Eurolab, we understand the importance of client confidentiality. Our lab follows strict protocols for data handling and storage to ensure that your information remains secure.

Conclusion

Microstructural analysis for failure analysis is a powerful tool for businesses seeking to minimize downtime, reduce costs, and ensure product safety. By investing in this laboratory service provided by Eurolab, companies can unlock the secrets of material failure, drive innovation, and maintain their competitive edge. Dont let material defects hold you back contact us today to learn more about our comprehensive microstructural analysis services.

Additional Resources

For further information on microstructural analysis for failure analysis or to discuss your specific needs, please refer to our Knowledge Center(https//example.com/knowledge-center) or visit our website at www.eurolab.com(http//www.eurolab.com).