Phase diagram analysis of alloy microstructures

Unlocking the Secrets of Alloy Microstructures The Power of Phase Diagram Analysis

In the world of materials science and engineering, understanding the intricacies of alloy microstructures is crucial for developing high-performance materials that meet specific requirements. One of the most effective tools in this pursuit is phase diagram analysis of alloy microstructures, a laboratory service provided by Eurolab. This specialized expertise enables businesses to optimize their material selection, processing conditions, and product design, ultimately leading to improved efficiency, reduced costs, and enhanced competitiveness.

What is Phase Diagram Analysis of Alloy Microstructures?

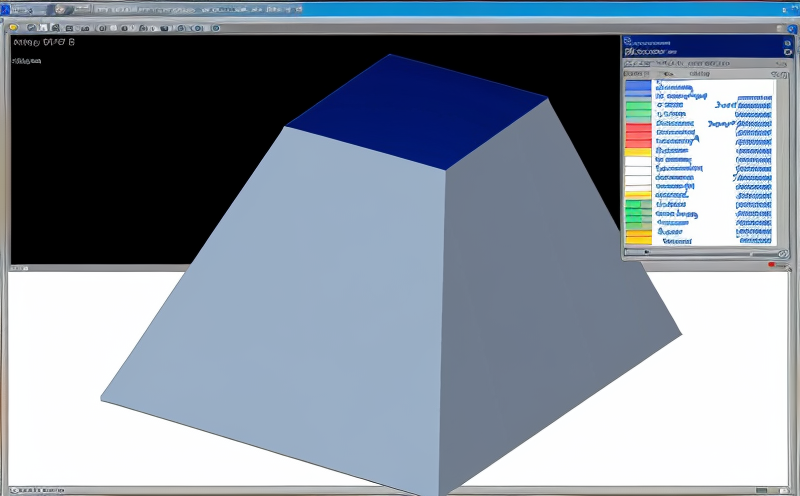

Phase diagram analysis of alloy microstructures is a scientific technique used to study the equilibrium relationships between different phases in an alloy. By examining these phase diagrams, researchers can identify the optimal composition, temperature, and processing conditions required to achieve desired material properties. This information is invaluable for materials scientists, engineers, and manufacturers seeking to develop innovative products with tailored characteristics.

The Importance of Phase Diagram Analysis

In todays fast-paced industrial landscape, companies must continually innovate and adapt to stay ahead of the competition. By leveraging phase diagram analysis of alloy microstructures, businesses can

Improve Material Selection Make informed decisions about material composition, ensuring that the chosen alloys meet specific requirements and minimize waste.

Optimize Processing Conditions Refine processing techniques, such as casting, forging, or machining, to achieve the desired microstructure and properties.

Enhance Product Performance Develop materials with tailored characteristics, including strength, ductility, corrosion resistance, and conductivity.

Reduce Development Time Accelerate product development by eliminating the need for trial-and-error approaches and relying on data-driven decision-making.

Advantages of Using Phase Diagram Analysis

Eurolabs phase diagram analysis service offers a wide range of benefits to businesses, including

Accurate Material Composition Identification Determine the exact composition of an alloy, ensuring that it meets specific requirements.

Predictive Modeling Use phase diagrams to forecast material behavior under various conditions, reducing the risk of unexpected performance issues.

Microstructure Control Design and control microstructures to achieve desired properties, such as grain size, shape, and distribution.

Cost Savings Optimize processing conditions and minimize waste by selecting the most suitable materials and techniques.

Additional Benefits

Improved Quality Ensure consistent material quality through precise control over composition and processing conditions.

Increased Efficiency Streamline production processes by identifying optimal material properties and reducing the need for costly rework.

Enhanced Competitiveness Stay ahead of competitors by leveraging advanced materials science expertise and proprietary knowledge.

Frequently Asked Questions

Q What is the purpose of phase diagram analysis?

A Phase diagram analysis helps researchers understand the equilibrium relationships between different phases in an alloy, enabling informed decisions about material composition, processing conditions, and product design.

Q How does Eurolabs service differ from other laboratory services?

A Our team of expert materials scientists uses cutting-edge techniques and proprietary knowledge to provide accurate and actionable results, ensuring that clients receive the most valuable insights possible.

Q Can phase diagram analysis be used for any type of alloy?

A Yes, our service is applicable to a wide range of alloys, including steels, titanium, aluminum, copper, and more.

Q How long does it take to conduct phase diagram analysis?

A The duration of the analysis depends on the complexity of the project, but our team typically completes analyses within 2-6 weeks.

Conclusion

Phase diagram analysis of alloy microstructures is a powerful tool for businesses seeking to optimize material selection, processing conditions, and product design. By leveraging Eurolabs expert knowledge and proprietary techniques, companies can unlock new opportunities for innovation, efficiency, and competitiveness. Whether youre developing high-performance materials or optimizing existing processes, our team is here to provide the insights and expertise needed to succeed in todays fast-paced industrial landscape.

Eurolabs phase diagram analysis service is designed to support your business goals, providing a comprehensive understanding of alloy microstructures that drives informed decision-making and accelerated innovation. Contact us today to learn more about how we can help you unlock the full potential of your materials.