Microstructure analysis of composite materials

Unlocking the Secrets of Composite Materials Why Microstructure Analysis is a Game-Changer for Businesses

In todays fast-paced and highly competitive business landscape, staying ahead of the curve requires more than just innovation it demands a deep understanding of the materials that drive your products and services. For companies working with composite materials, which are becoming increasingly prevalent in industries such as aerospace, automotive, and construction, one critical aspect of material analysis stands out Microstructure analysis.

At Eurolab, our team of experts has been at the forefront of providing cutting-edge laboratory services to businesses seeking to optimize their products performance. Our Microstructure analysis of composite materials service is a powerful tool that enables companies to unlock the full potential of their materials and stay ahead in the market. But what exactly does this laboratory service entail, and why is it essential for businesses?

What is Microstructure Analysis of Composite Materials?

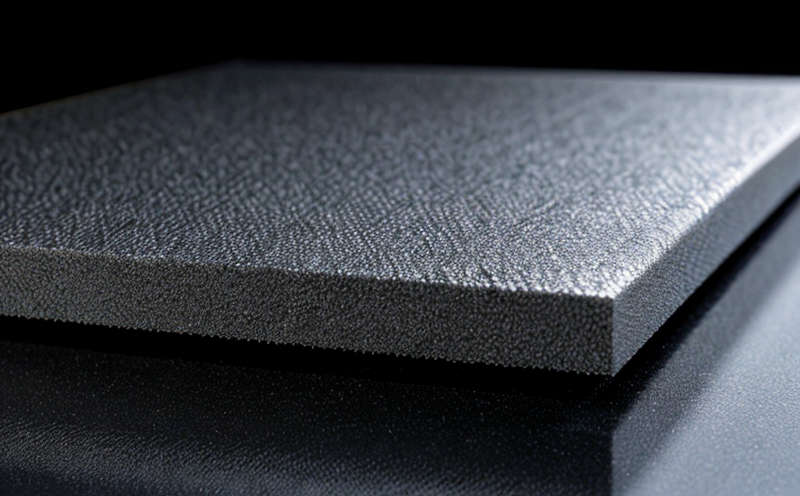

Microstructure analysis of composite materials involves the examination of the internal structure of these materials at a microscopic level. This includes evaluating the arrangement and interaction of various components such as fibers, matrices, and reinforcements, which together give composites their unique properties.

Composites are used in a wide range of applications due to their exceptional strength-to-weight ratio, resistance to fatigue, and corrosion. However, understanding the microstructure is crucial for predicting material behavior under different conditions, ensuring reliability, and optimizing performance. This laboratory service uses advanced techniques such as scanning electron microscopy (SEM), transmission electron microscopy (TEM), and energy-dispersive spectroscopy (EDS) to provide a detailed picture of the composites internal structure.

The Advantages of Microstructure Analysis of Composite Materials

Our Microstructure analysis of composite materials service offers numerous benefits for businesses working with these materials. Here are some key advantages

Improved Material Performance By understanding the microstructure, manufacturers can optimize material properties such as strength, stiffness, and toughness, leading to improved overall performance.

Reduced Risk of Failure Analyzing the internal structure helps identify potential weaknesses or defects that could lead to failure under stress. This proactive approach minimizes the risk of costly failures and reputational damage.

Increased Product Lifespan By understanding how materials degrade over time, companies can develop strategies to extend product lifespan, reduce maintenance costs, and minimize waste.

Compliance with Regulations In regulated industries like aerospace and automotive, understanding the microstructure is essential for compliance with industry standards and regulatory requirements.

Competitive Advantage Companies that leverage Microstructure analysis of composite materials gain a competitive edge by delivering high-performance products that meet or exceed customer expectations.

Cost Savings By identifying areas where material properties can be improved, companies can reduce costs associated with rework, retesting, and waste disposal.

RD Acceleration Microstructure analysis facilitates the development process by providing insights into how materials respond to different conditions, accelerating innovation and time-to-market.

Enhanced Customer Satisfaction By delivering products that meet or exceed customer expectations, companies can build trust, loyalty, and a strong reputation in their market.

QA Your Questions Answered

Weve compiled a comprehensive QA section to address your most pressing questions about Microstructure analysis of composite materials

What types of composite materials can be analyzed using this service?

Our experts can analyze various types of composites, including carbon fiber reinforced polymers (CFRP), glass fiber reinforced polymers (GFRP), and ceramic matrix composites (CMC).

How does Microstructure analysis differ from other material testing methods?

Unlike traditional testing methods that focus on macroscopic properties, Microstructure analysis examines the internal structure at a microscopic level to understand material behavior.

Can I provide my own samples for analysis?

Yes! Our team will work with you to ensure your samples are prepared and analyzed according to your specific needs and requirements.

What kind of expertise do your analysts bring to this service?

Our analysts have extensive experience working with composite materials, ensuring that they can accurately interpret results and provide actionable insights for our clients.

How long does the analysis process typically take?

Turnaround times vary depending on sample complexity and analysis requirements, but we aim to deliver high-quality reports within 2-4 weeks.

Can I request custom analysis protocols or testing methods?

Absolutely! Our team will work closely with you to develop a customized protocol that meets your specific needs and research objectives.

How do I access the results of my Microstructure analysis?

We provide detailed, easy-to-understand reports that include visualizations, data tables, and actionable recommendations for improving material performance.

Conclusion

In todays fast-paced business environment, staying ahead requires a deep understanding of the materials driving your products and services. Eurolabs Microstructure analysis of composite materials service empowers businesses to unlock the full potential of their materials, ensuring reliability, optimizing performance, and gaining a competitive edge in the market. Whether youre seeking to improve material properties, reduce risk, or accelerate innovation, our expert team is here to help.

By leveraging the power of Microstructure analysis, companies can transform their products into high-performance assets that meet or exceed customer expectations. Dont miss out on this opportunity to take your business to the next level partner with Eurolab today!