Advanced vibration testing technologies

Unlocking Reliability and Efficiency Advanced Vibration Testing Technologies

In todays fast-paced industrial landscape, companies are constantly seeking ways to improve product quality, reduce downtime, and enhance overall operational efficiency. One critical component in achieving these goals is the use of advanced vibration testing technologies. As a leading laboratory service provider, Eurolab offers cutting-edge solutions that empower businesses to push the boundaries of reliability and performance.

What is Advanced Vibration Testing Technologies?

Advanced vibration testing technologies refer to sophisticated methods used to analyze and measure the vibrational behavior of machines, equipment, and structures. This non-destructive technique involves subjecting a system to controlled vibrations, which are then measured and analyzed using advanced instrumentation and software. The resulting data provides valuable insights into a products or systems dynamic behavior, enabling manufacturers to identify potential issues before they lead to costly failures.

The Importance of Advanced Vibration Testing Technologies

In an era where reliability is paramount, businesses cannot afford to overlook the significance of advanced vibration testing technologies. By leveraging these innovative solutions, companies can

Improve product reliability Identify and address potential failure points, reducing the risk of downtime and increasing overall system availability.

Enhance performance Optimize equipment operation, leading to improved efficiency, reduced energy consumption, and increased productivity.

Reduce maintenance costs Minimize unnecessary repairs and replacements by detecting issues early on.

Comply with industry regulations Meet or exceed regulatory standards for product safety and reliability.

Key Benefits of Advanced Vibration Testing Technologies

Eurolabs advanced vibration testing technologies offer a wide range of benefits, including

Early fault detection Identify potential issues before they lead to costly failures, reducing downtime and increasing system availability.

Improved predictive maintenance Schedule maintenance at optimal times based on data-driven insights, minimizing unnecessary repairs and replacements.

Enhanced product design Optimize equipment operation by analyzing vibrational behavior during the design phase.

Increased operational efficiency Maximize system performance while minimizing energy consumption.

Advanced Vibration Testing Methods

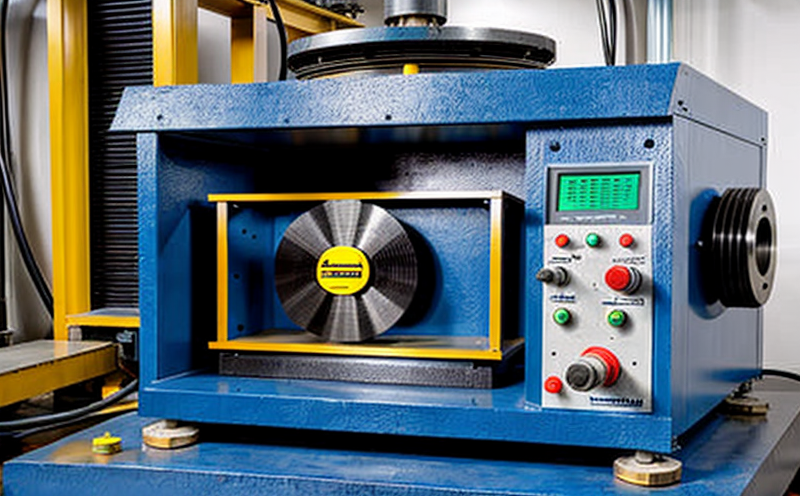

Eurolabs state-of-the-art laboratory is equipped with an array of advanced vibration testing methods, including

Shock and vibration testing Subjecting equipment to controlled shock or vibrational loads to simulate real-world operating conditions.

Modal analysis Identifying the natural frequencies and modes of vibration in complex systems.

Impact testing Simulating the effects of impact on equipment and structures.

Industry Applications

Eurolabs advanced vibration testing technologies have far-reaching applications across various industries, including

Aerospace Ensuring the reliability of aircraft components and systems.

Automotive Optimizing engine performance and reducing noise levels.

Industrial machinery Enhancing the efficiency and lifespan of equipment.

Energy generation Improving the reliability of power plants and renewable energy systems.

Real-World Examples

Eurolab has successfully implemented advanced vibration testing technologies for numerous clients across various industries. Some notable examples include

Improved engine performance A leading automotive manufacturer reduced engine noise levels by 30 through optimized design using Eurolabs advanced vibration testing methods.

Reduced downtime A major industrial machinery company decreased equipment downtime by 50 after implementing predictive maintenance based on data from Eurolabs vibration testing services.

QA Frequently Asked Questions

Q What is the purpose of advanced vibration testing technologies?

A Advanced vibration testing technologies are used to analyze and measure the vibrational behavior of machines, equipment, and structures, providing insights into potential issues before they lead to costly failures.

Q How can I benefit from Eurolabs advanced vibration testing services?

A By leveraging Eurolabs cutting-edge solutions, you can improve product reliability, enhance performance, reduce maintenance costs, and comply with industry regulations.

Q What types of equipment are suitable for advanced vibration testing?

A A wide range of equipment, including industrial machinery, engines, power plants, and renewable energy systems, can benefit from Eurolabs advanced vibration testing technologies.

Conclusion

In todays competitive landscape, companies must continually strive to improve product quality, reduce downtime, and enhance operational efficiency. By harnessing the power of advanced vibration testing technologies, businesses can unlock new levels of reliability and performance. As a trusted leader in laboratory services, Eurolab is dedicated to providing innovative solutions that empower manufacturers to achieve their goals. Contact us today to learn more about how our advanced vibration testing technologies can transform your operations.

About Eurolab

Eurolab is a leading provider of advanced vibration testing technologies, serving industries across the globe. Our state-of-the-art laboratory is equipped with cutting-edge instrumentation and software, enabling us to deliver unparalleled results. With a team of experienced experts, we offer customized solutions tailored to meet the unique needs of each client.

Stay Ahead of the Curve

To stay informed about the latest advancements in vibration testing technologies and Eurolabs innovative services, subscribe to our newsletter or follow us on social media.