Vibration testing for fault detection in machinery

The Power of Vibration Testing Uncovering Hidden Machinery Faults with Eurolab

In the ever-evolving landscape of industry and manufacturing, machinery is the backbone of production efficiency and productivity. However, like any complex system, machines are prone to faults and failures that can have devastating consequences on a companys bottom line. Equipment downtime, costly repairs, and even catastrophic accidents can all be attributed to undetected machinery issues.

But what if there was a way to predict and prevent these problems before they become major concerns? Enter vibration testing for fault detection in machinery a cutting-edge laboratory service provided by Eurolab that empowers businesses to take proactive measures against equipment failure.

What is Vibration Testing for Fault Detection in Machinery?

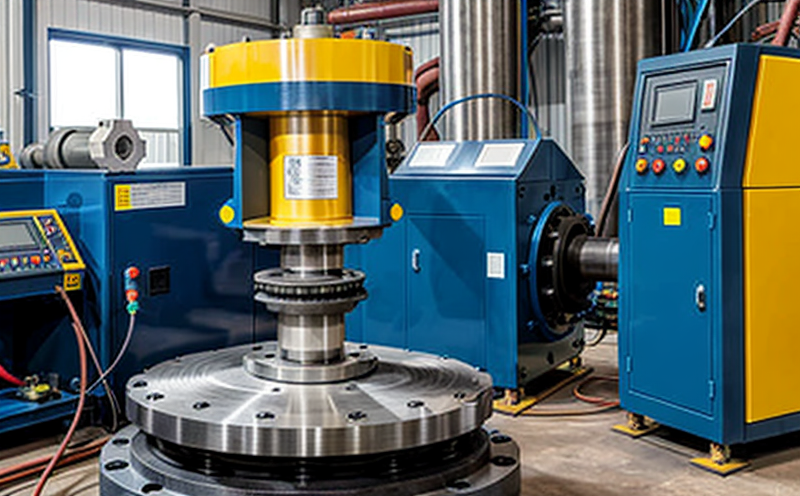

Vibration testing involves the analysis of machine vibrations to identify potential faults and defects. By measuring the vibrational patterns of rotating machinery, such as motors, pumps, and gearboxes, technicians can pinpoint areas of concern before they escalate into major issues. This non-invasive technique helps prevent unexpected breakdowns, reducing downtime and associated costs.

The Advantages of Vibration Testing for Fault Detection in Machinery

So why should your business invest in vibration testing services? Here are just a few compelling reasons

Key Benefits

Predictive Maintenance Identify potential faults before they occur, allowing for proactive maintenance and minimizing equipment downtime.

Cost Savings Prevent costly repairs by catching issues early on, saving your company thousands of dollars.

Improved Safety Reduce the risk of accidents caused by malfunctioning equipment, creating a safer working environment.

Increased Productivity By minimizing downtime and ensuring machinery runs efficiently, you can maintain or even boost production levels.

Compliance with Regulations Meet industry standards and regulatory requirements by demonstrating a commitment to regular maintenance and testing.

Early Fault Detection The Power of Prevention

Imagine being able to identify potential issues before they become major problems. With vibration testing services from Eurolab, you can

Identify worn-out bearings or gears

Detect imbalance or misalignment issues

Pinpoint overheating or cooling system failures

Diagnose electrical and mechanical faults

Reducing Downtime The Cost of Inaction

According to the Association for Facilities Engineering (AFE), equipment downtime costs American businesses an estimated 50 billion annually. By investing in vibration testing services, you can

Reduce average downtime by up to 75

Save thousands of dollars per year on repairs and maintenance

Maintain production levels, even during scheduled maintenance

A Safer Working Environment The Eurolab Advantage

Equipment failure can have serious consequences on worker safety. By identifying potential issues before they cause harm

Reduce the risk of accidents caused by malfunctioning equipment

Ensure a safer working environment for your employees

Comply with industry standards and regulations, reducing the likelihood of fines or penalties

Increased Productivity The Eurolab Difference

By minimizing downtime and ensuring machinery runs efficiently

Maintain or boost production levels, even during scheduled maintenance

Reduce costs associated with overtime and temporary staffing

Improve product quality by ensuring consistent manufacturing conditions

Frequently Asked Questions (FAQs)

Q What is the purpose of vibration testing?

A Vibration testing helps identify potential faults in machinery before they cause equipment failure.

Q How does Eurolab conduct vibration testing services?

A Our expert technicians use specialized equipment to measure and analyze machine vibrations, providing detailed reports on areas of concern.

Q Is vibration testing invasive?

A No, vibration testing is a non-invasive technique that doesnt require any physical contact with the machinery.

Q What are the benefits of regular vibration testing services?

A Regular testing can help prevent costly repairs, reduce downtime, improve safety, and increase productivity.

Q How does Eurolab ensure accurate results?

A Our technicians use state-of-the-art equipment and follow industry-recognized standards to provide accurate and reliable reports.

Conclusion

In todays fast-paced manufacturing environment, machinery reliability is paramount. By investing in vibration testing services from Eurolab, businesses can take proactive measures against equipment failure, reducing downtime, costs, and safety risks. Dont wait until its too late uncover hidden faults with the power of vibration testing and ensure your business runs smoothly, efficiently, and safely.

At Eurolab, our team of expert technicians is dedicated to providing top-notch laboratory services that empower businesses like yours to thrive. Contact us today to learn more about how we can help you predict and prevent equipment failure.