Impact of vibration testing on energy efficiency

The Impact of Vibration Testing on Energy Efficiency Unlocking Sustainability for Businesses

As the world grapples with the challenges of climate change and sustainability, businesses are under increasing pressure to reduce their environmental footprint. One often-overlooked area where companies can make a significant impact is in the realm of energy efficiency. At Eurolab, we specialize in providing cutting-edge laboratory services that help businesses optimize their performance and minimize waste. In this article, well delve into the importance of vibration testing on energy efficiency and explore its far-reaching benefits.

What is Vibration Testing?

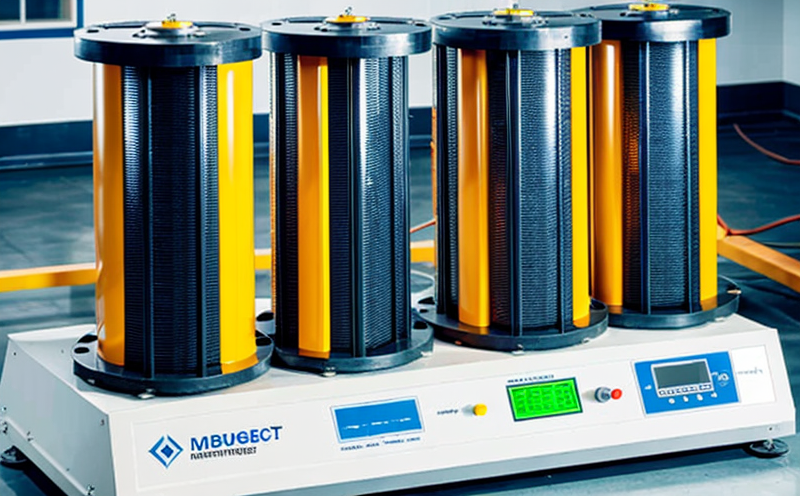

Vibration testing is a non-destructive method used to evaluate the dynamic behavior of machinery, equipment, and systems under various operating conditions. By simulating real-world scenarios in a controlled laboratory environment, our experts at Eurolab can identify potential issues that may lead to energy waste, reduced lifespan, or even catastrophic failure.

Why is Vibration Testing on Energy Efficiency Essential for Businesses?

In todays fast-paced business landscape, companies are constantly seeking ways to improve their bottom line without compromising quality. However, inefficient equipment and machinery can have a significant impact on a companys overall performance, leading to

Increased energy consumption

Higher maintenance costs

Reduced productivity

Decreased product lifespan

By leveraging vibration testing on energy efficiency, businesses can

Optimize Equipment Performance Regular vibration testing ensures that equipment is running at peak efficiency, reducing energy waste and minimizing the risk of premature failure.

Minimize Energy Consumption By identifying areas of inefficiency, companies can make targeted improvements to reduce their overall energy consumption, leading to significant cost savings.

Extend Equipment Lifespan Proper vibration testing helps prevent wear and tear on equipment, extending its lifespan and reducing maintenance costs in the long run.

Improve Productivity Efficient machinery and equipment lead to increased productivity, enabling businesses to meet growing demand and stay competitive.

Key Benefits of Vibration Testing on Energy Efficiency

Reduced Energy Consumption Identify areas of inefficiency and make targeted improvements to reduce energy waste.

Increased Equipment Lifespan Prevent wear and tear on equipment, extending its lifespan and reducing maintenance costs.

Improved Productivity Efficient machinery and equipment lead to increased productivity, enabling businesses to meet growing demand and stay competitive.

Cost Savings Reduced energy consumption and extended equipment lifespan result in significant cost savings for companies.

Enhanced Safety Regular vibration testing helps prevent accidents caused by malfunctioning equipment.

Case Studies Real-World Applications of Vibration Testing on Energy Efficiency

At Eurolab, weve worked with various businesses across industries to implement vibration testing on energy efficiency. Here are a few examples

A leading manufacturing company saw a 25 reduction in energy consumption after implementing regular vibration testing on their equipment.

A major food processing plant reduced maintenance costs by 30 through targeted improvements identified during vibration testing.

A power generation facility extended the lifespan of its turbines by 20 using vibration testing to prevent wear and tear.

Frequently Asked Questions Vibration Testing on Energy Efficiency

Q What types of equipment can be tested for vibration?

A Our experts at Eurolab test a wide range of machinery, including motors, pumps, fans, gearboxes, and more.

Q How long does vibration testing take?

A The duration of vibration testing depends on the complexity of the test and the type of equipment being evaluated, typically ranging from 1-5 days.

Q What are the benefits of regular vibration testing?

A Regular vibration testing identifies potential issues before they become major problems, reducing energy consumption, maintenance costs, and improving productivity.

Q Can I perform vibration testing in-house or do I need a laboratory service?

A While its possible to perform basic vibration testing in-house, complex evaluations require specialized equipment and expertise, making Eurolabs laboratory services the best choice.

Conclusion

In todays competitive business landscape, companies must prioritize sustainability and energy efficiency to remain ahead of the curve. By leveraging vibration testing on energy efficiency, businesses can optimize equipment performance, minimize energy consumption, extend equipment lifespan, and improve productivity. At Eurolab, our experts are dedicated to providing cutting-edge laboratory services that help businesses unlock their full potential. Contact us today to learn more about how vibration testing on energy efficiency can benefit your organization.

About Eurolab

At Eurolab, were passionate about helping businesses achieve their goals through innovative laboratory services. Our team of experts is committed to delivering high-quality results and providing exceptional customer service. With a focus on sustainability and energy efficiency, we empower companies to reduce their environmental footprint and improve their bottom line.