Vibration testing of hydraulic systems

The Power of Vibration Testing Ensuring the Reliability and Efficiency of Hydraulic Systems

In todays fast-paced industrial landscape, businesses are constantly striving to optimize their operations, reduce costs, and minimize downtime. One critical aspect of achieving these goals is ensuring the reliability and efficiency of hydraulic systems, which play a vital role in various industries such as manufacturing, construction, and oil and gas. At Eurolab, our team of experts provides comprehensive laboratory services, including vibration testing of hydraulic systems. This cutting-edge technology helps identify potential issues before they cause costly damage or disruption to production.

What is Vibration Testing of Hydraulic Systems?

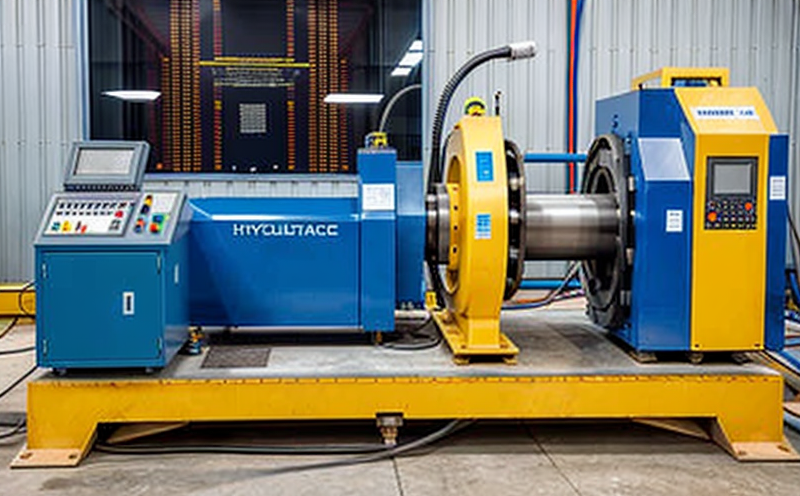

Vibration testing of hydraulic systems involves using advanced equipment to simulate real-world operating conditions and measure the response of a systems components to various frequencies and amplitudes. By analyzing these data, our experts can identify potential problems, such as loose connections, worn-out seals, or inadequate fluid viscosity, which can lead to premature wear, reduced performance, and increased maintenance costs.

Why is Vibration Testing of Hydraulic Systems Essential for Businesses?

The importance of vibration testing of hydraulic systems cannot be overstated. Here are some compelling reasons why businesses should prioritize this laboratory service

Prevents Unplanned Downtime By identifying potential issues before they cause equipment failure, vibration testing helps minimize downtime and maintain production schedules.

Reduces Maintenance Costs Early detection of problems enables targeted maintenance, reducing unnecessary repairs and extending the lifespan of hydraulic systems.

Improves System Efficiency Vibration testing ensures that hydraulic systems operate within optimal parameters, resulting in improved performance, increased productivity, and reduced energy consumption.

Enhances Operator Safety By identifying potential hazards, vibration testing helps prevent accidents and injuries related to equipment malfunction or misuse.

Benefits of Using Vibration Testing of Hydraulic Systems

Here are the key benefits of incorporating vibration testing into your hydraulic system maintenance routine

Early Warning System Identifies potential issues before they cause equipment failure or downtime

Cost Savings Reduces maintenance costs by preventing unnecessary repairs and extending equipment lifespan

Improved Performance Ensures hydraulic systems operate within optimal parameters, resulting in improved productivity and efficiency

Increased Uptime Minimizes unplanned downtime and maintains production schedules

Operator Safety Prevents accidents and injuries related to equipment malfunction or misuse

How Does Vibration Testing of Hydraulic Systems Work?

The process involves the following steps

System Preparation Our team prepares the hydraulic system for testing by attaching sensors and connecting the test equipment.

Data Collection The test equipment simulates real-world operating conditions, collecting data on vibration frequencies, amplitudes, and resonance points.

Data Analysis Our experts analyze the collected data to identify potential issues, such as loose connections or worn-out seals.

Recommendations and Implementation We provide recommendations for corrective actions, which are then implemented by our team or your maintenance personnel.

QA Section

Q What types of hydraulic systems can be tested?

A Our vibration testing services can accommodate various types of hydraulic systems, including pumps, motors, valves, and cylinders.

Q How long does a typical vibration test take?

A The duration of the test depends on the complexity of the system and the specific requirements. Typically, tests last between 2-5 hours.

Q What kind of data is collected during the test?

A We collect data on vibration frequencies, amplitudes, resonance points, and other relevant parameters to identify potential issues.

Q Can I witness the testing process?

A Yes, our team welcomes clients to observe the testing process. However, please note that this may require prior arrangements.

Q What kind of expertise do your technicians possess?

A Our technicians are highly trained and experienced in vibration testing, hydraulic system maintenance, and repair.

Conclusion

Vibration testing of hydraulic systems is a critical laboratory service that helps businesses prevent unplanned downtime, reduce maintenance costs, improve system efficiency, and enhance operator safety. At Eurolab, our team of experts provides comprehensive services to ensure the reliability and efficiency of your hydraulic systems. By incorporating vibration testing into your maintenance routine, you can enjoy significant benefits and stay ahead in todays competitive industrial landscape.

Get Started with Vibration Testing Today

Dont let potential issues compromise your operations. Contact us at Eurolab to schedule a vibration test for your hydraulic system and experience the power of reliable and efficient equipment.