Impact of vibration testing on machine performance

The Impact of Vibration Testing on Machine Performance Unlocking Efficiency and Reliability

In todays fast-paced industrial landscape, machine performance is the lifeblood of businesses worldwide. Companies rely heavily on their equipment to operate efficiently, meet production targets, and maintain customer satisfaction. However, machinery can be prone to vibrations, which can have a significant impact on its overall performance. This is where vibration testing comes into play a crucial laboratory service that ensures your machines are running at optimal levels.

At Eurolab, our team of experts provides comprehensive vibration testing services to help businesses like yours optimize their machine performance, reduce downtime, and increase productivity. In this article, well delve into the world of vibration testing, exploring its benefits, advantages, and why its an essential tool for any industry looking to stay ahead.

What is Vibration Testing?

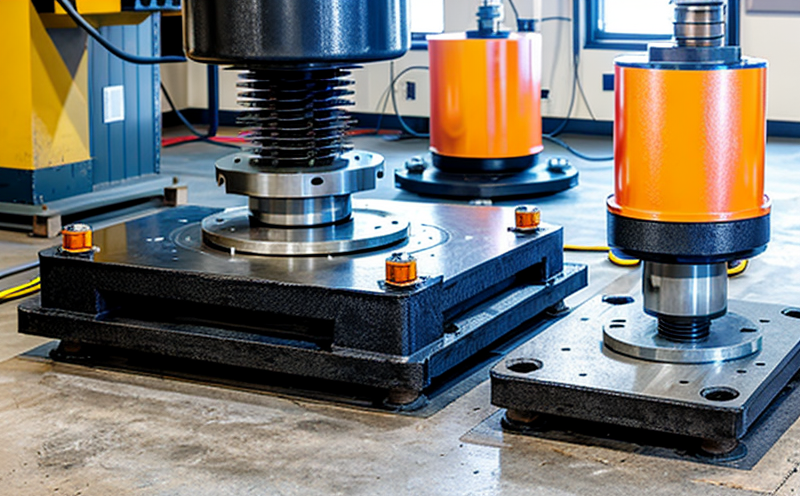

Vibration testing involves measuring and analyzing the vibrations of a machine or equipment to identify potential issues before they cause damage or failure. This laboratory service uses specialized equipment to simulate real-world operating conditions, allowing our experts to evaluate a machines performance under various loads and stresses.

The Advantages of Vibration Testing Why Your Business Needs It

Eurolabs vibration testing services offer numerous benefits that can make a significant impact on your business. Here are some key advantages

Increased Efficiency By identifying potential issues early, you can prevent equipment failures, reducing downtime and increasing overall productivity.

Improved Reliability Vibration testing helps ensure that machines operate at optimal levels, resulting in consistent performance and reduced maintenance costs.

Reduced Energy Consumption Properly maintained equipment consumes less energy, leading to cost savings and a lower carbon footprint.

Enhanced Safety By detecting potential problems before they cause damage or failure, you can create a safer working environment for your employees.

Compliance with Industry Regulations Many industries require regular vibration testing to ensure compliance with safety standards and regulations.

Extended Equipment Lifespan Regular vibration testing helps prevent premature wear and tear, extending the lifespan of your equipment and reducing replacement costs.

How Vibration Testing Works

Our state-of-the-art laboratory is equipped with advanced equipment to simulate real-world operating conditions. Our experts follow a comprehensive process to ensure accurate and reliable results

Machine Preparation We carefully prepare each machine for testing by removing any protective covers and ensuring its in a suitable condition.

Vibration Measurement Specialized sensors are attached to the machine to measure its vibrations, which are then transmitted to our analysis software.

Data Analysis Our experts analyze the data to identify potential issues, such as imbalances or misalignments, which can be causing excessive vibration.

Reporting and Recommendations We provide a detailed report outlining our findings and recommendations for correction, including any necessary repairs or adjustments.

Frequently Asked Questions (FAQs)

Q What types of machines require vibration testing?

A Any machine that operates at high speeds or under heavy loads, such as engines, gearboxes, and pumps, can benefit from vibration testing.

Q How often should I conduct vibration testing on my equipment?

A Regular testing is recommended every 6-12 months, depending on the machines usage and operating conditions.

Q What are the benefits of using Eurolabs vibration testing services?

A Our expert team provides accurate and reliable results, ensuring your machines operate at optimal levels while reducing downtime and maintenance costs.

Q Can I conduct vibration testing in-house or do I need to send my equipment to a laboratory?

A While some companies attempt to conduct their own vibration testing, its often more cost-effective and accurate to outsource the service to a specialized laboratory like Eurolab.

Conclusion

In todays competitive business environment, machine performance is crucial for success. Eurolabs vibration testing services are designed to help you optimize your equipments performance, reduce downtime, and increase productivity. By investing in our expert analysis, you can

Increase efficiency and reliability

Reduce energy consumption and maintenance costs

Enhance safety standards and compliance with industry regulations

Extend the lifespan of your equipment

Dont let vibrations hold back your business potential contact Eurolab today to schedule a comprehensive vibration testing service. Our team is committed to helping you achieve peak performance, ensuring your machines operate at their best for years to come.