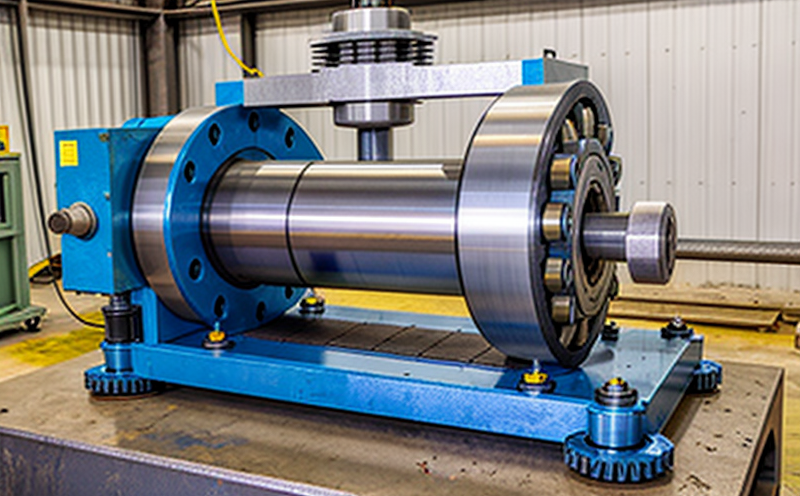

Vibration testing of bearings and gears

Unlocking Reliability The Crucial Role of Vibration Testing in Bearings and Gears

In todays fast-paced industrial landscape, ensuring the reliability and longevity of mechanical components is paramount for businesses to maintain productivity, minimize downtime, and stay ahead of the competition. At Eurolab, we specialize in providing state-of-the-art laboratory services that help companies like yours achieve these goals. One such essential service is Vibration testing of bearings and gears a critical process that helps identify potential issues before they cause costly failures.

What is Vibration Testing?

Vibration testing, also known as vibration analysis or vibration monitoring, is a non-destructive technique used to measure the vibrations of rotating machinery components like bearings and gears. By analyzing these vibrations, our team at Eurolab can detect subtle anomalies that may indicate impending failure, allowing you to take corrective action before its too late.

Why Vibration Testing Matters for Businesses

The benefits of vibration testing are multifaceted and far-reaching, making it an indispensable tool in the arsenal of any serious manufacturer or operator. Some of the most compelling advantages include

Predictive Maintenance Identify potential issues before they cause costly failures, reducing downtime and increasing overall productivity.

Improved Reliability Extend the lifespan of your bearings and gears by detecting anomalies early on, minimizing the risk of premature wear-out.

Enhanced Efficiency Optimize machine performance by eliminating vibrations that can lead to reduced efficiency, increased energy consumption, and decreased quality output.

Reduced Costs Minimize repair and replacement costs by addressing issues before they become major problems.

Compliance with Industry Regulations Ensure compliance with industry standards and regulations regarding vibration levels and measurement.

Key Benefits of Vibration Testing

Our Vibration testing service is designed to provide you with a comprehensive understanding of your bearings and gears health. Some key benefits include

Detailed Reports Receive thorough, easy-to-understand reports detailing the results of our tests, including recommendations for improvement.

Expert Analysis Our team of experienced engineers will analyze your data, providing expert insights into any issues detected.

Customized Solutions Based on our findings, well work with you to develop customized solutions tailored to your specific needs.

The Vibration Testing Process

At Eurolab, we employ cutting-edge technology and rigorous methodologies to ensure accurate and reliable results. Our Vibration testing process involves the following steps

Instrumentation We use state-of-the-art vibration measurement equipment to capture data on your bearings and gears vibrations.

Data Acquisition Our systems collect and store detailed information about the vibrations, including frequency, amplitude, and other relevant parameters.

Analysis Our team of experts analyzes the collected data, identifying any anomalies or potential issues.

Reporting We provide you with comprehensive reports detailing our findings, along with recommendations for improvement.

Frequently Asked Questions (FAQs)

Weve compiled a list of frequently asked questions to help address common concerns and misconceptions about Vibration testing

Q What types of bearings and gears can be tested using this method?

A Our service is suitable for various types of bearings, including ball bearings, roller bearings, and more. We also test gears, such as spur gears, helical gears, and bevel gears.

Q How long does the Vibration testing process take?

A The duration of our tests can vary depending on the specific requirements and complexity of your equipment. However, most tests typically range from a few hours to several days.

Q What kind of equipment do you use for vibration measurement?

A We employ high-precision vibration measurement systems that ensure accurate data collection and analysis.

Q Can Vibration testing be used to diagnose issues with non-rotating machinery components?

A While our primary focus is on bearings and gears, we can also analyze other rotating machinery components using similar methods.

Conclusion

In todays fast-paced industrial environment, its more crucial than ever to ensure the reliability and longevity of mechanical components. At Eurolab, our Vibration testing service provides businesses with a powerful tool for predicting maintenance needs, improving efficiency, reducing costs, and ensuring compliance with industry regulations. By partnering with us, youll gain access to expert analysis, detailed reporting, and customized solutions tailored to your specific needs.

Dont wait until its too late trust Eurolab to help you unlock the full potential of your bearings and gears through our comprehensive Vibration testing services. Contact us today to learn more about how we can support your operations!