Analysis techniques used in vibration testing

The Power of Analysis Techniques in Vibration Testing Unlocking Reliability and Efficiency for Your Business

In todays fast-paced industrial landscape, the importance of ensuring equipment reliability cannot be overstated. With increasing demands on production capacity and decreasing tolerance for downtime, businesses must prioritize maintenance strategies that prevent costly breakdowns and optimize performance. One critical laboratory service that plays a vital role in achieving these objectives is vibration testing analysis. At Eurolab, our team of expert technicians employ advanced analysis techniques to help clients identify potential issues before they become major problems.

What is Vibration Testing Analysis?

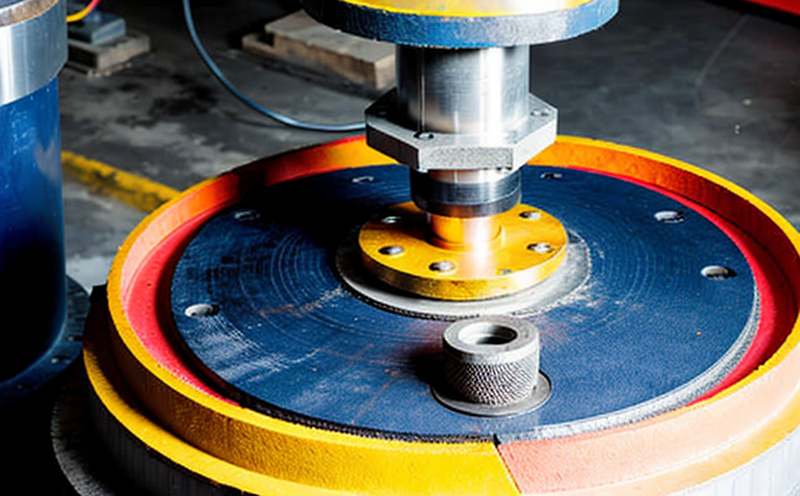

Vibration testing analysis involves using specialized equipment and software to measure the vibrational patterns of machinery and equipment under various operating conditions. This non-destructive testing method allows for the identification of subtle abnormalities that can indicate impending failure or malfunctions. By analyzing these vibrations, our team at Eurolab can provide detailed insights into the mechanical condition of your equipment, enabling informed maintenance decisions and proactive repair strategies.

The Advantages of Using Analysis Techniques in Vibration Testing

Early Detection of Potential Issues

Identifies subtle abnormalities that indicate impending failure or malfunctions

Enables early intervention to prevent costly downtime and extended maintenance schedules

Optimized Maintenance Scheduling

Helps schedule maintenance activities at optimal times, reducing unnecessary shutdowns and increasing overall productivity

Allows for the allocation of resources more efficiently, prioritizing critical tasks and minimizing waste

Improved Equipment Reliability

Enhances equipment reliability by identifying potential failure points before they become major issues

Reduces the likelihood of unexpected breakdowns and associated costs

Increased Productivity and Reduced Costs

Minimizes downtime and increases overall productivity, directly impacting bottom-line revenue

Helps businesses avoid costly repairs, replacement parts, and labor expenses by addressing issues early on

Compliance with Industry Regulations and Standards

Ensures compliance with industry regulations and standards related to equipment maintenance and safety

Demonstrates a commitment to quality and reliability, enhancing your businesss reputation in the market

Key Benefits of Analysis Techniques Used in Vibration Testing

Identifies potential issues before they become major problems, reducing downtime and increasing productivity.

Optimizes maintenance scheduling, allocating resources more efficiently and minimizing waste.

Enhances equipment reliability by addressing potential failure points early on.

Helps businesses avoid costly repairs, replacement parts, and labor expenses.

QA Frequently Asked Questions About Analysis Techniques Used in Vibration Testing

Q What types of equipment can be analyzed using vibration testing analysis?

A A wide range of industrial equipment can be analyzed using vibration testing analysis, including but not limited to engines, gearboxes, pumps, compressors, and generators.

Q How does vibration testing analysis differ from traditional maintenance strategies?

A Vibration testing analysis is a non-destructive testing method that provides detailed insights into the mechanical condition of your equipment. Unlike traditional methods, which often involve trial-and-error or destructive testing, vibration testing analysis allows for proactive maintenance scheduling and early detection of potential issues.

Q What kind of data can be collected from vibration testing analysis?

A Vibration testing analysis collects a range of data points related to the vibrational patterns of your equipment. This includes frequency spectrum analysis, time waveform analysis, and other metrics that provide insights into the mechanical condition of your machinery.

Q Can vibration testing analysis help reduce maintenance costs?

A Yes, vibration testing analysis can significantly reduce maintenance costs by identifying potential issues early on. By addressing these issues proactively, businesses can avoid costly repairs, replacement parts, and labor expenses associated with unexpected breakdowns.

Conclusion Unlock the Full Potential of Your Equipment with Analysis Techniques Used in Vibration Testing

At Eurolab, we understand the critical role that analysis techniques used in vibration testing play in ensuring equipment reliability and optimizing maintenance strategies. By leveraging our advanced analysis techniques, businesses can identify potential issues before they become major problems, optimize maintenance scheduling, enhance equipment reliability, increase productivity, and reduce costs.

Dont let equipment downtime hold your business back. Contact us today to learn more about how Eurolabs vibration testing analysis services can help you unlock the full potential of your equipment and drive success in an increasingly competitive market.