Evaluating material durability through vibration testing

Evaluating Material Durability through Vibration Testing A Crucial Service for Businesses

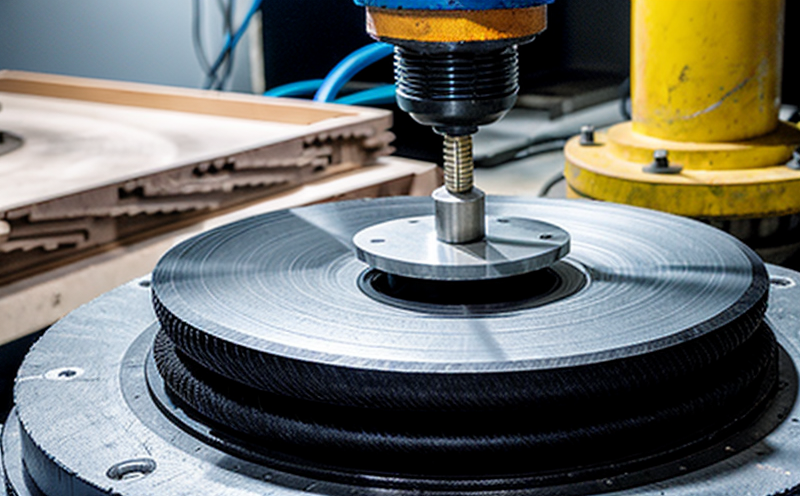

In todays fast-paced manufacturing industry, ensuring the durability and reliability of materials is crucial to preventing costly downtime, reducing waste, and enhancing overall product quality. One effective method for evaluating material durability is vibration testing, a specialized laboratory service provided by Eurolab. This non-destructive technique simulates real-world conditions, allowing businesses to predict how their products will perform under various stressors.

As the demand for high-performance materials continues to grow, companies are seeking innovative ways to validate their products robustness and longevity. Vibration testing is an indispensable tool in this pursuit, offering a cost-effective means of assessing material integrity before mass production begins. By leveraging Eurolabs expertise in vibration testing, businesses can ensure that their products meet the highest standards of quality, safety, and performance.

The Advantages of Evaluating Material Durability through Vibration Testing

Eurolabs vibration testing service offers numerous benefits to manufacturers and suppliers across various industries. Some key advantages include

Predictive Maintenance By simulating real-world stressors, vibration testing enables businesses to anticipate potential material failures, allowing for proactive maintenance and minimizing unexpected downtime.

Reduced Material Waste Identifying weaknesses in materials before production ensures that only high-quality components are used, reducing waste and associated costs.

Improved Product Reliability Vibration testing helps manufacturers identify areas of improvement, enabling them to enhance product design and material selection for optimal performance.

Enhanced Customer Satisfaction By providing products with a proven track record of durability and reliability, businesses can foster long-term customer loyalty and trust.

Compliance with Industry Regulations Many industries require rigorous testing to ensure compliance with safety standards. Vibration testing helps companies meet these requirements, reducing the risk of recalls and reputational damage.

How Vibration Testing Works

Eurolabs vibration testing process involves several key stages

Sample Preparation Test samples are carefully prepared and handled to minimize contamination and ensure accurate results.

Vibration Profiling The test equipment is calibrated, and the specific vibration profile is selected based on the products intended use case.

Testing and Data Collection The sample undergoes controlled vibration testing, with data collected in real-time to assess material response and potential failure points.

Data Analysis Expert analysts interpret the results, providing actionable insights for improving product design and material selection.

Benefits of Working with Eurolab

When partnering with Eurolab for vibration testing, businesses can expect

Expertise and Experience Our team of specialists has extensive knowledge in materials science and testing protocols.

State-of-the-Art Equipment We utilize cutting-edge technology to ensure accurate and reliable results.

Flexibility and Customization Our services are tailored to meet the unique needs of each client, accommodating diverse product types and industries.

QA Section

Q What types of materials can be tested using vibration testing?

A Vibration testing is applicable to a wide range of materials, including metals, polymers, composites, ceramics, and more. Our experts will work with you to determine the best approach for your specific material requirements.

Q How long does the testing process typically take?

A The duration of vibration testing varies depending on the complexity of the test and the type of data being collected. Typically, tests can be completed within a few days or weeks, but we also offer ongoing testing programs to accommodate longer-term product development needs.

Q What are the advantages of non-destructive testing?

A Non-destructive testing (NDT) methods like vibration testing allow for material evaluation without damage or destruction. This is particularly beneficial when dealing with high-value or critical components, as it eliminates waste and preserves valuable resources.

Q How does Eurolab ensure data accuracy and confidentiality?

A Our team follows strict protocols to maintain data integrity and confidentiality. We use secure data storage systems and only share results with authorized personnel.

Conclusion

Evaluating material durability through vibration testing is an indispensable service for businesses seeking to optimize product performance, reduce waste, and enhance customer satisfaction. By partnering with Eurolab, manufacturers can tap into the expertise of our specialists and leverage cutting-edge equipment to achieve unparalleled insights into their materials capabilities. Whether youre developing high-performance components or seeking to improve existing products, Eurolabs vibration testing service is an essential tool for achieving success in todays competitive market.

Incorporating this comprehensive laboratory service into your product development process will provide a significant return on investment by minimizing potential liabilities, ensuring compliance with industry regulations, and driving long-term growth through enhanced customer loyalty. Dont compromise on material quality choose Eurolabs vibration testing services to unlock the full potential of your products.