Assessing PCB Durability in High-Temperature Environments

Assessing PCB Durability in High-Temperature Environments Ensuring the Reliability of Your Electronics

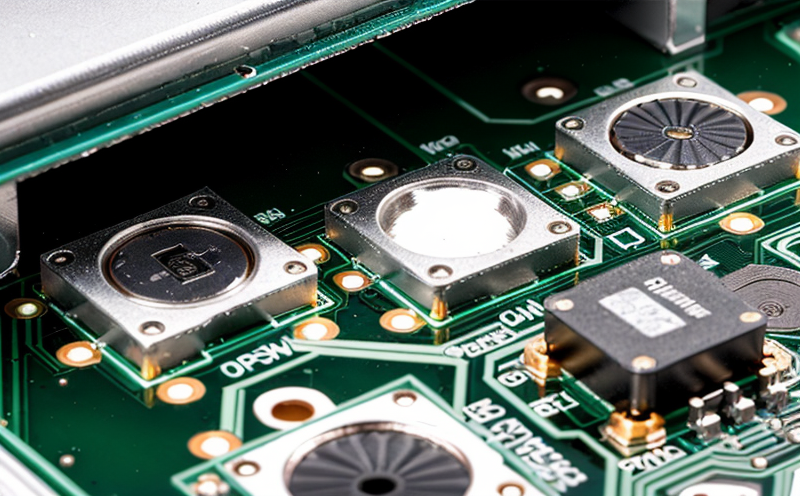

In todays fast-paced world, electronic devices are an integral part of our daily lives. From smartphones and laptops to industrial control systems and medical equipment, printed circuit boards (PCBs) are the backbone of modern electronics. However, these components can be prone to damage when exposed to high temperatures, which can have catastrophic consequences for businesses and industries that rely on them.

High-temperature environments are becoming increasingly common in various sectors, including automotive, aerospace, and industrial manufacturing. When electronic devices are subjected to extreme temperatures, the risk of component failure increases significantly, leading to costly downtime, reduced productivity, and compromised product quality. In such situations, assessing PCB durability in high-temperature environments becomes crucial for ensuring the reliability and performance of electronics.

What is Assessing PCB Durability in High-Temperature Environments?

Assessing PCB durability in high-temperature environments involves testing the ability of printed circuit boards to withstand extreme temperatures without sustaining damage or compromising their functionality. This laboratory service evaluates the thermal stability and reliability of PCBs, providing critical insights into their performance under various temperature conditions.

At Eurolab, our experienced team of engineers and technicians utilize state-of-the-art equipment to simulate high-temperature environments and assess the durability of your PCBs. Our comprehensive testing services help identify potential weaknesses and vulnerabilities, enabling you to take proactive measures to mitigate risks and ensure the reliability of your electronics.

Advantages of Assessing PCB Durability in High-Temperature Environments

Using our laboratory service has numerous benefits for businesses and industries that rely on electronic components

Reduced Downtime By identifying potential weaknesses and vulnerabilities, you can take corrective actions to prevent component failure, minimizing downtime and ensuring continuous production.

Improved Product Reliability Assessing PCB durability in high-temperature environments helps ensure that your electronics can withstand extreme temperatures without compromising their functionality, leading to improved product reliability and reduced warranty claims.

Enhanced Quality Control Our testing services enable you to validate the thermal stability of your PCBs, ensuring that they meet or exceed industry standards for temperature resistance.

Increased Product Lifespan By understanding how your PCBs perform under high-temperature conditions, you can take steps to extend their lifespan and reduce maintenance costs.

Compliance with Industry Regulations Our laboratory service helps ensure compliance with relevant industry regulations and standards, such as IPC 9691 for temperature testing of electronic components.

Key Benefits of Assessing PCB Durability in High-Temperature Environments

Here are the key benefits of using our laboratory service

Precise Temperature Control Our state-of-the-art equipment enables precise control over temperature conditions, ensuring accurate and reliable test results.

Comprehensive Testing Services We offer a range of testing services, including temperature cycling, thermal shock, and high-temperature storage, to evaluate the durability of your PCBs under various conditions.

Quick Turnaround Times Our experienced team works efficiently to deliver rapid turnaround times without compromising on accuracy or quality.

Customized Solutions We tailor our testing services to meet the specific needs of your business, providing customized solutions that address unique challenges and requirements.

Frequently Asked Questions (FAQs)

Here are some frequently asked questions about assessing PCB durability in high-temperature environments

Q What types of electronic components can be tested using this service?

A Our laboratory service is applicable to a wide range of electronic components, including printed circuit boards (PCBs), integrated circuits (ICs), and other semiconductor devices.

Q How do you simulate high-temperature environments during testing?

A We utilize state-of-the-art equipment that simulates extreme temperature conditions, allowing us to accurately assess the thermal stability and reliability of your PCBs.

Q Can I request customized testing services for my specific application or industry?

A Yes, we offer customized solutions tailored to meet the unique needs of your business, ensuring accurate and relevant results.

Q What kind of reporting and documentation can I expect from the testing process?

A We provide comprehensive test reports, including detailed analysis and recommendations for improvement, as well as certification documents for regulatory compliance purposes.

Conclusion

Assessing PCB durability in high-temperature environments is a critical laboratory service that helps ensure the reliability and performance of electronic components. At Eurolab, our experienced team utilizes state-of-the-art equipment to simulate extreme temperature conditions and evaluate the thermal stability of your PCBs. By using our comprehensive testing services, you can reduce downtime, improve product reliability, enhance quality control, increase product lifespan, and comply with industry regulations.

Dont compromise on the reliability of your electronics. Contact us today to learn more about our laboratory service and how it can benefit your business.