Ensuring the Reliability of Your Electronics The Importance of PCB Integrity Testing

In todays fast-paced world of electronics manufacturing, ensuring the quality and reliability of your products is crucial to maintaining customer satisfaction and avoiding costly recalls. One critical aspect of achieving this goal is through the use of Printed Circuit Board (PCB) integrity testing services. Eurolabs advanced laboratory capabilities provide unparalleled insights into the performance and durability of your PCBs, helping you identify potential issues before they become major problems.

What is PCB Integrity Testing?

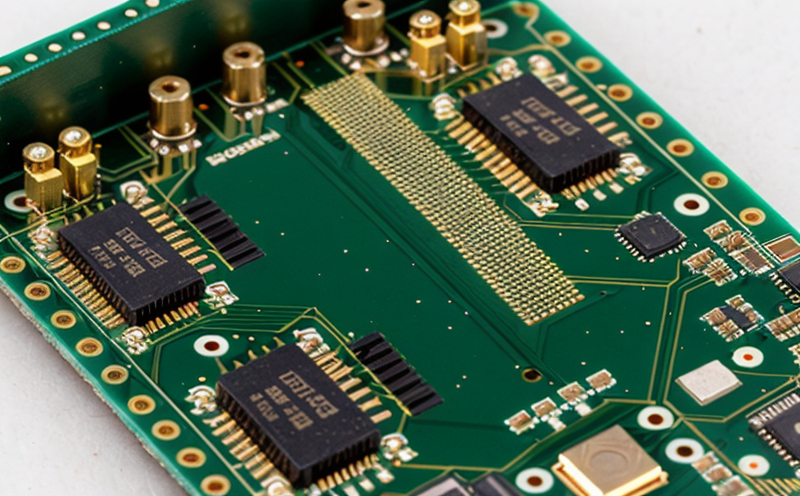

PCB integrity testing involves a thorough examination of the electrical properties and structural soundness of printed circuit boards. This process assesses various aspects of the boards design, materials, and construction to ensure that it meets the required standards for reliability and performance. At Eurolab, our team of experienced engineers and technicians utilize state-of-the-art equipment to perform a comprehensive analysis of your PCBs, providing you with actionable data to inform your manufacturing process.

Why is PCB Integrity Testing Essential?

Incorporating PCB integrity testing into your quality control processes offers numerous benefits that can have a significant impact on your bottom line. Some of the key advantages include

Reduced Risk of Product Failure By identifying potential issues early on, you can prevent costly recalls and minimize the risk of product failure.

Improved Manufacturing Efficiency With accurate data from PCB integrity testing, you can streamline your manufacturing process by optimizing production runs and reducing waste.

Enhanced Customer Satisfaction Trustworthy products are more likely to meet customer expectations, leading to increased loyalty and repeat business.

Increased Competitive Advantage Companies that prioritize quality and reliability stand out in the market, attracting customers who value their commitment to excellence.

Benefits of PCB Integrity Testing

Here are some key benefits of using PCB integrity testing services

Early Detection of Design Flaws Our expert analysis helps identify potential design errors or flaws that could compromise the performance of your PCBs.

Inspection and Analysis of Materials We examine the types and properties of materials used in your PCBs, ensuring they meet industry standards for reliability and durability.

Evaluation of Manufacturing Processes Our testing services assess the manufacturing process to ensure it is adequate for producing high-quality PCBs.

Identification of Potential Failure Points By analyzing the boards electrical properties, we can pinpoint potential failure points before they become major issues.

What Does the Testing Process Entail?

Our comprehensive testing process involves a multi-step approach that covers various aspects of your PCBs. The following is an overview of what you can expect

Sample Preparation We receive and prepare your PCB samples for analysis.

Electrical Testing Our team conducts electrical tests to evaluate the boards performance under different conditions.

Visual Inspection A thorough visual inspection is performed to identify any visible defects or damage.

Material Analysis We analyze the materials used in the PCBs, including solder joints, copper, and insulating layers.

Data Review and Reporting Our expert team reviews the test results and provides a comprehensive report highlighting key findings.

QA Addressing Your Concerns About PCB Integrity Testing

We understand you may have questions about our testing services. Here are some frequently asked questions (FAQs) to address common concerns

Q How long does the testing process take?

A The duration of our testing services varies depending on the complexity and number of samples submitted.

Q What types of PCBs can be tested?

A We offer testing for a wide range of PCB applications, including consumer electronics, industrial equipment, and aerospace components.

Q Can I get customized testing services tailored to my specific needs?

A Yes! Our team is happy to work with you to create a customized testing plan that meets your unique requirements.

Q How do I submit samples for testing?

A Please contact us via our website or through our online portal to arrange for sample submission and scheduling.

Conclusion

In the world of electronics manufacturing, ensuring PCB integrity is crucial for maintaining product reliability and customer satisfaction. By incorporating Eurolabs comprehensive PCB integrity testing services into your quality control processes, you can

Reduce risk of product failure

Improve manufacturing efficiency

Enhance customer satisfaction

Increase competitive advantage

Dont compromise on the reliability of your electronics products. Partner with us today to ensure your PCBs meet the highest standards for performance and durability.

About Eurolab

Eurolab is a cutting-edge laboratory dedicated to delivering high-quality testing services for the electronics industry. With state-of-the-art equipment, expert technicians, and an unwavering commitment to quality, we empower businesses to make informed decisions about their products reliability and performance.