Testing PCB for Resistance to Vibration and Shock

Testing PCB for Resistance to Vibration and Shock Ensuring the Reliability of Your Electronics

In todays fast-paced business world, electronics play a vital role in driving innovation and productivity. From smart home devices to industrial machinery, electronic components are an integral part of our daily lives. However, these components can be susceptible to various environmental stresses, including vibration and shock. Prolonged exposure to these forces can lead to damage, malfunction, or even complete failure.

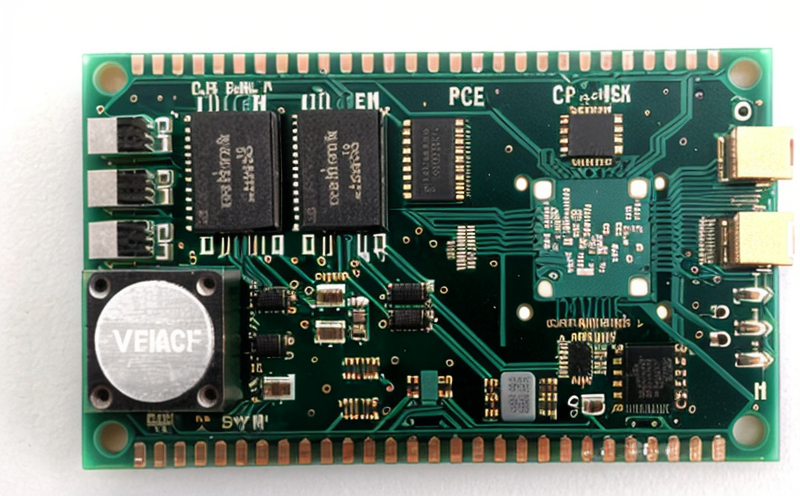

To mitigate this risk, businesses need to ensure that their printed circuit boards (PCBs) can withstand the rigors of real-world use. This is where Testing PCB for Resistance to Vibration and Shock comes in a laboratory service provided by Eurolab that simulates the effects of vibration and shock on electronic components, giving you peace of mind and protecting your investment.

What is Testing PCB for Resistance to Vibration and Shock?

Testing PCB for Resistance to Vibration and Shock involves subjecting PCBs to controlled levels of vibration and shock, mimicking the conditions they may encounter in real-world applications. This simulation helps identify potential weaknesses or vulnerabilities that could compromise the performance and reliability of your electronic components.

Our experts at Eurolab use state-of-the-art equipment to apply carefully calibrated levels of vibration and shock, allowing us to assess the impact on various aspects of your PCBs, including

Component stability

Signal integrity

Power supply stability

Data storage reliability

By testing for resistance to vibration and shock, you can ensure that your electronics are designed to withstand the stresses they may face in service.

Advantages of Testing PCB for Resistance to Vibration and Shock

The benefits of testing your PCBs for resistance to vibration and shock are numerous. Here are just a few

Improved reliability By identifying potential weaknesses or vulnerabilities, you can redesign or modify your PCBs to withstand the stresses they may encounter in service.

Reduced downtime A reliable electronics system means reduced maintenance costs and increased productivity, as equipment is less likely to fail or require repairs.

Cost savings Preventing damage or failure before it occurs saves time, money, and resources that would otherwise be spent on repair or replacement.

Enhanced customer satisfaction Delivering high-quality products that meet the needs of your customers leads to increased loyalty, retention, and ultimately, revenue growth.

Key Benefits

Here are some key benefits of Testing PCB for Resistance to Vibration and Shock

Assessment of component stability Identify potential issues with component placement or orientation.

Evaluation of signal integrity Determine how vibration and shock affect the quality of signals transmitted through your PCBs.

Verification of power supply stability Ensure that your PCBs can maintain a stable power supply in the face of vibration and shock.

Data storage reliability assurance Test the durability of data storage components, such as flash memory or hard drives.

QA Testing PCB for Resistance to Vibration and Shock

We understand that you may have questions about Testing PCB for Resistance to Vibration and Shock. Here are some frequently asked questions

Q What types of equipment can be tested using this service?

A Our testing services cover a wide range of electronic components, including printed circuit boards (PCBs), connectors, switches, and other assemblies.

Q How do you simulate the effects of vibration and shock on our PCBs?

A We use specialized equipment that applies controlled levels of vibration and shock to your PCBs, simulating the conditions they may encounter in real-world applications.

Q Can I get a quote for this service?

A Yes, please contact us with details about your project or component design, and well provide you with a customized quote.

Conclusion

In todays fast-paced business world, electronics play a critical role in driving innovation and productivity. However, these components can be susceptible to various environmental stresses, including vibration and shock. Testing PCB for Resistance to Vibration and Shock provided by Eurolab ensures that your electronic components are designed to withstand the rigors of real-world use.

By identifying potential weaknesses or vulnerabilities, you can improve reliability, reduce downtime, and save costs. Our comprehensive testing services give you peace of mind, allowing you to focus on what matters most delivering high-quality products to your customers.

Dont let environmental stresses compromise the performance and reliability of your electronics. Contact us today to learn more about Testing PCB for Resistance to Vibration and Shock and how it can benefit your business.