Examining the Solderability of PCB Pads

Examining the Solderability of PCB Pads Ensuring Reliability and Efficiency in Electronic Manufacturing

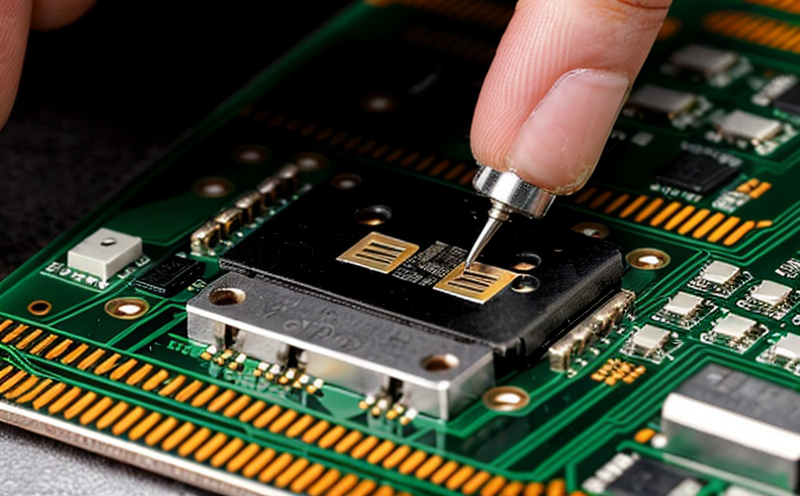

In todays fast-paced world of electronics manufacturing, quality control is more crucial than ever. With increasing demand for high-performance products, businesses must ensure that their components meet stringent standards to maintain competitiveness and customer satisfaction. One critical aspect of electronic manufacturing is the solderability of Printed Circuit Board (PCB) pads. A reliable method for examining these pads is essential to guarantee the integrity and reliability of electronic devices.

What is Examining the Solderability of PCB Pads?

Examining the solderability of PCB pads involves evaluating the ability of a printed circuit boards surface finishes to facilitate strong, reliable solder joints. This laboratory service helps manufacturers identify potential issues with their components before they enter production, ensuring that their products meet quality and reliability standards.

Why is Examining the Solderability of PCB Pads Important?

The importance of examining the solderability of PCB pads cannot be overstated. It plays a vital role in

Ensuring Product Reliability Poor solder joints can lead to equipment failure, costly downtime, and damaged reputation.

Reducing Costs Identifying issues early on saves time and resources by preventing rework or replacement of defective components.

Enhancing Efficiency By optimizing production processes, manufacturers can streamline their workflow, increase productivity, and meet tight deadlines.

Compliance with Regulations Meeting industry standards for solderability helps companies avoid costly recalls and maintain a competitive edge in the market.

Key Benefits of Examining the Solderability of PCB Pads

Here are some key benefits of using Eurolabs examining the solderability of PCB pads laboratory service

Improved Product Quality Our comprehensive analysis ensures that your components meet the highest standards for reliability and performance.

Reduced Time-to-Market By identifying issues early on, you can accelerate production schedules without compromising quality.

Enhanced Brand Reputation Demonstrating a commitment to quality helps establish trust with customers and builds a positive reputation in the industry.

Increased Efficiency Our expert analysis saves time and resources by pinpointing potential problems before they enter production.

Eurolabs Expertise

At Eurolab, our experienced technicians employ state-of-the-art equipment and rigorous testing protocols to examine the solderability of PCB pads. We offer

Comprehensive Analysis Our thorough examination covers all aspects of solderability, including surface finish, pad geometry, and component compatibility.

Accurate Results Our expert analysis provides reliable results, ensuring that you make informed decisions about your production processes.

Customized Solutions We work closely with clients to develop tailored testing plans that meet their specific needs.

Frequently Asked Questions (FAQs)

What is the purpose of examining the solderability of PCB pads?

To evaluate the ability of a printed circuit boards surface finishes to facilitate strong, reliable solder joints.

Why is solderability important in electronic manufacturing?

Poor solder joints can lead to equipment failure, costly downtime, and damaged reputation.

What benefits does examining the solderability of PCB pads provide?

Improved product quality, reduced time-to-market, enhanced brand reputation, and increased efficiency.

How does Eurolabs laboratory service differ from other testing providers?

Our expert analysis employs state-of-the-art equipment and rigorous testing protocols to ensure accurate results.

Conclusion

In the competitive world of electronic manufacturing, examining the solderability of PCB pads is a critical component of quality control. By using Eurolabs comprehensive laboratory service, businesses can ensure the reliability and efficiency of their products, meet industry standards for compliance, and maintain a positive reputation in the market.

By partnering with Eurolab, you can

Ensure product reliability and performance

Reduce costs associated with rework or replacement of defective components

Enhance your brand reputation through commitment to quality

Increase efficiency by streamlining production processes

Choose Eurolabs examining the solderability of PCB pads laboratory service for peace of mind in electronic manufacturing. Contact us today to learn more about our comprehensive analysis and expert solutions.