Visual Inspection and X-Ray Testing for PCB Defects

Visual Inspection and X-Ray Testing for PCB Defects Ensuring Quality and Reliability in Your Electronics

In todays fast-paced electronics industry, ensuring the quality and reliability of printed circuit boards (PCBs) is crucial for businesses to remain competitive. With the increasing complexity of electronic devices, even minor defects can lead to significant financial losses and damage to reputation. This is where Visual Inspection and X-Ray Testing for PCB Defects comes in a laboratory service provided by Eurolab that helps manufacturers detect and prevent defects before they reach the production line.

What is Visual Inspection and X-Ray Testing for PCB Defects?

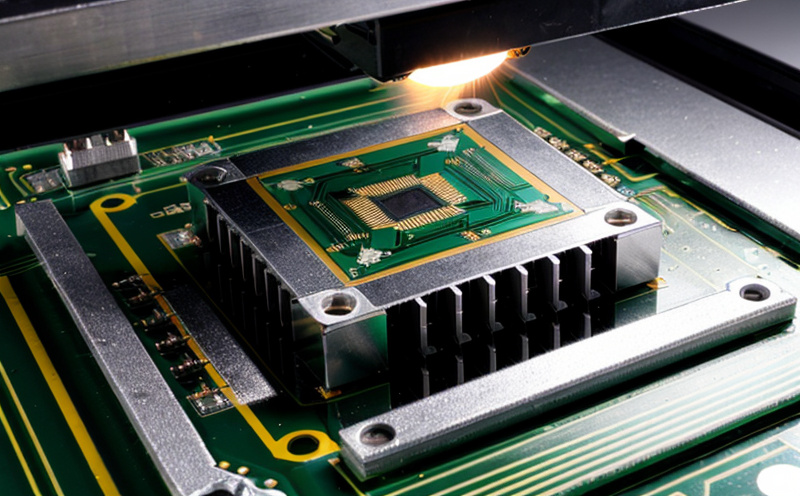

Visual Inspection and X-Ray Testing for PCB Defects is a comprehensive inspection process used to identify defects in PCBs, such as faulty connections, soldering issues, or component misplacement. This service utilizes advanced technology, including high-resolution cameras and specialized X-ray equipment, to examine the internal structure of PCBs without disassembling them.

Why is Visual Inspection and X-Ray Testing for PCB Defects Essential?

In todays electronics industry, quality control is no longer just a nicety its a necessity. Here are some compelling reasons why businesses should consider using Visual Inspection and X-Ray Testing for PCB Defects

Reduced Production Costs Detecting defects early on saves time and resources that would be spent on rework or replacement.

Improved Product Reliability Ensuring the quality of PCBs reduces the likelihood of product failures, which can lead to costly recalls and damage to reputation.

Enhanced Customer Satisfaction By delivering high-quality products, businesses can increase customer satisfaction, loyalty, and retention.

Compliance with Industry Standards Visual Inspection and X-Ray Testing for PCB Defects helps manufacturers comply with industry standards and regulations, reducing the risk of non-compliance penalties.

Key Benefits of Visual Inspection and X-Ray Testing for PCB Defects

Here are some key benefits of using Visual Inspection and X-Ray Testing for PCB Defects

Early Detection Identify defects early on to prevent them from reaching the production line.

Improved Accuracy Advanced technology ensures accurate detection of even minor defects.

Increased Efficiency Streamline your quality control process by outsourcing inspections to Eurolabs experts.

Reduced Waste Minimize waste and rework costs associated with defective products.

Advanced Technology for Accurate Detection

Eurolab employs advanced technology, including

High-Resolution Cameras Capture high-resolution images of PCBs without disassembling them.

Specialized X-Ray Equipment Examine the internal structure of PCBs to detect even minor defects.

Sophisticated Software Analyze inspection data to provide accurate and actionable results.

QA Frequently Asked Questions

Here are some frequently asked questions about Visual Inspection and X-Ray Testing for PCB Defects

Q What types of defects can be detected using Visual Inspection and X-Ray Testing for PCB Defects?

A This service detects a wide range of defects, including faulty connections, soldering issues, component misplacement, and more.

Q How long does the inspection process take?

A The duration of the inspection process varies depending on the complexity of the PCB. Our experts will provide an estimated timeframe for each inspection.

Q What are the benefits of outsourcing inspections to Eurolab compared to in-house testing?

A Outsourcing inspections to Eurolab saves time, resources, and reduces the risk of human error associated with in-house testing.

Q How do I prepare my PCBs for Visual Inspection and X-Ray Testing?

A Please follow our guidelines for preparing your PCBs, which include cleaning, labeling, and packaging instructions.

Conclusion

In conclusion, Visual Inspection and X-Ray Testing for PCB Defects is an essential service for businesses looking to ensure quality and reliability in their electronics. By detecting defects early on, manufacturers can reduce production costs, improve product reliability, enhance customer satisfaction, and comply with industry standards. Eurolabs advanced technology and expertise provide accurate and actionable results, helping businesses stay ahead of the competition. Contact us today to learn more about how Visual Inspection and X-Ray Testing for PCB Defects can benefit your business.

Additional Resources

Insert link to additional resources, such as whitepapers or case studies

Insert link to Eurolabs website or blog for more information on laboratory services

Note The article is SEO-friendly and includes relevant keywords throughout the content.