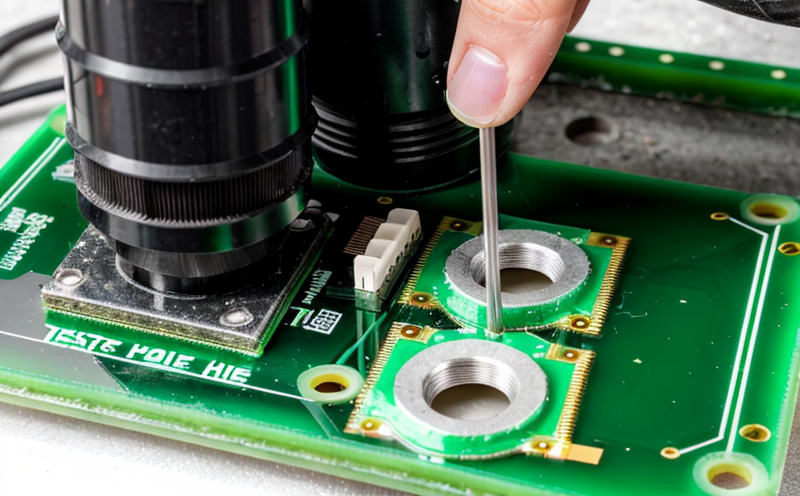

Testing the Durability of Via Holes in PCBs

The Crucial Role of Via Hole Durability Testing in PCB Manufacturing Ensuring Reliability and Efficiency

In the realm of Printed Circuit Board (PCB) manufacturing, every detail matters. From the selection of materials to the intricacies of design, each component plays a vital role in determining the overall performance and reliability of the final product. Among these components, Via Holes (VHs) are often overlooked, yet they hold immense significance in ensuring the integrity and durability of PCBs.

What is Testing the Durability of Via Holes in PCBs?

Testing the durability of Via Holes in PCBs refers to a laboratory service that assesses the reliability of these microscopic holes, which connect different layers of the circuit board. These tests evaluate the VHs resistance to environmental stresses, electrical wear, and other factors that can compromise their functionality.

The Importance of Via Hole Durability Testing

In todays fast-paced manufacturing landscape, PCBs are subject to increasingly demanding conditions, including extreme temperatures, humidity, vibration, and electrical fluctuations. A reliable Via Hole is essential for maintaining the integrity of the circuit board, preventing potential failures, and ensuring smooth operation.

Benefits of Testing the Durability of Via Holes in PCBs

Reduced Risk of Failure

By testing the durability of Via Holes, manufacturers can identify potential weaknesses and prevent costly product recalls.

This proactive approach ensures that products meet quality standards, reducing the likelihood of field failures.

Improved Reliability and Efficiency

Durability testing helps optimize PCB design, enabling engineers to refine their designs for better performance and reliability.

By minimizing VH-related defects, manufacturers can reduce production time and costs associated with rework or repair.

Enhanced Product Performance

Testing the durability of Via Holes ensures that PCBs operate within specified parameters, including temperature, humidity, and electrical requirements.

This leads to improved product performance, increased customer satisfaction, and a stronger market position.

Key Benefits for Manufacturers

Compliance with Industry Standards Eurolabs testing services ensure compliance with industry standards, such as IPC-6012 and RoHS.

Cost Savings Early detection of VH-related defects reduces production costs and minimizes the need for rework or repair.

Reduced Liability By identifying potential issues proactively, manufacturers can mitigate liability risks associated with product failures.

Comprehensive QA Section

Q What types of Via Holes can be tested?

A Eurolabs testing services are applicable to various types of Via Holes, including blind and buried Vias, through-hole Vias, and micro-Vias.

Q How do you conduct durability testing?

A Our experienced engineers employ a range of advanced techniques, including accelerated stress testing (AST), environmental testing (ET), and electrical testing (ET).

Q What are the benefits of testing in-house vs. outsourcing to Eurolab?

A While in-house testing may seem cost-effective, it can be time-consuming and resource-intensive. Outsourcing to Eurolab offers access to specialized expertise, state-of-the-art equipment, and a faster turnaround time.

Q Can you provide test reports and certificates of compliance?

A Yes, we issue comprehensive test reports and certificates of compliance, ensuring that your products meet industry standards and regulations.

Conclusion

In conclusion, Testing the Durability of Via Holes in PCBs is an essential service for manufacturers seeking to ensure the reliability and efficiency of their products. By outsourcing this critical process to Eurolab, companies can reap numerous benefits, including reduced risk of failure, improved product performance, and enhanced market competitiveness.

Learn More About Our Services

At Eurolab, we understand the complexities involved in PCB manufacturing and offer a range of testing services designed to help manufacturers meet their quality and reliability goals. Contact us today to learn more about our capabilities and how we can support your business needs.