Evaluating PCB Performance Under Mechanical Stress

Evaluating PCB Performance Under Mechanical Stress Why Your Business Needs It

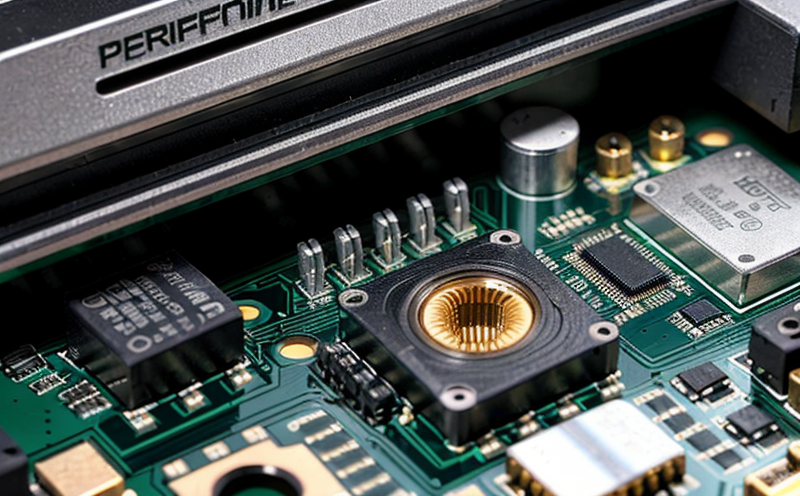

In todays fast-paced and highly competitive electronics industry, the reliability of printed circuit boards (PCBs) is more critical than ever. As technology advances, PCBs are increasingly being used in a wide range of applications, from consumer electronics to aerospace and defense systems. However, with increased complexity comes increased risk of mechanical stress-related failures.

Mechanical stress, which can be caused by temperature changes, vibration, or other external factors, can compromise the integrity of your PCBs and lead to costly downtime, reduced product lifespan, and damage to your brand reputation. To mitigate these risks, its essential to evaluate your PCB performance under mechanical stress. At Eurolab, our laboratory service provides a comprehensive evaluation of your PCBs resilience against mechanical stress, helping you identify potential weaknesses and improve their overall reliability.

What is Evaluating PCB Performance Under Mechanical Stress?

Evaluating PCB performance under mechanical stress involves subjecting your boards to various forms of mechanical loading, such as bending, twisting, or compression. This process simulates real-world conditions and allows us to assess how your PCBs will perform in situations where they may be exposed to stress.

Our state-of-the-art laboratory equipment enables us to precisely control the magnitude and duration of the mechanical load applied to your PCBs. We then analyze the results to identify any weaknesses or vulnerabilities that could lead to failure. This information is crucial for manufacturers, engineers, and designers who need to ensure their products meet stringent performance and reliability standards.

Advantages of Using Evaluating PCB Performance Under Mechanical Stress

Our laboratory service offers numerous benefits to businesses operating in the electronics industry

Improved product reliability By identifying potential weaknesses and vulnerabilities, we help you design and manufacture PCBs that are more robust and less prone to mechanical stress-related failures.

Reduced costs Avoid costly rework, repair, or replacement of faulty PCBs by catching potential issues early on in the development process.

Enhanced brand reputation Meet customer expectations for high-quality products and maintain a positive reputation through increased reliability and performance.

Compliance with industry standards Our evaluation services help you meet regulatory requirements and industry standards for mechanical stress testing, such as IPC-

Increased efficiency By streamlining your design and manufacturing process, we enable you to bring products to market faster and more efficiently.

Key Benefits of Evaluating PCB Performance Under Mechanical Stress

Here are some key benefits of using our laboratory service

Early failure detection Identify potential weaknesses in your PCBs before they reach the end-consumer, reducing waste and minimizing costs.

Optimized design Our evaluation services help you refine your PCB designs to improve performance under mechanical stress.

Supply chain assurance Verify that your suppliers products meet your reliability requirements and reduce the risk of supply chain disruptions.

Reduced warranty claims Minimize the number of warranty claims related to mechanical stress-related failures, protecting your brand reputation and bottom line.

How Does Evaluating PCB Performance Under Mechanical Stress Work?

Our evaluation process involves several steps

Sample preparation We carefully prepare a representative sample of your PCBs for testing.

Mechanical loading Our state-of-the-art equipment applies controlled mechanical loads to the PCBs, simulating real-world conditions.

Data acquisition and analysis We collect data on the PCBs performance under stress and analyze the results using advanced software tools.

Reporting and recommendations We provide a detailed report outlining our findings and offer expert recommendations for improving your PCB designs.

QA Evaluating PCB Performance Under Mechanical Stress

What types of mechanical loads can be applied to PCBs?

Our laboratory equipment enables us to apply various forms of mechanical loading, including bending, twisting, compression, and vibration.

Can you test large quantities of PCBs?

Yes, we have the capacity to test large batches of PCBs quickly and efficiently using our state-of-the-art equipment.

Do I need to send my entire production run for testing?

No, we can select a representative sample from your production batch to evaluate performance under mechanical stress.

What kind of data do you collect during the evaluation process?

We collect detailed data on the PCBs performance, including any signs of failure or degradation under mechanical stress.

Conclusion

Evaluating PCB performance under mechanical stress is an essential service that helps manufacturers and engineers ensure their products meet stringent performance and reliability standards. At Eurolab, our laboratory service provides a comprehensive evaluation of your PCBs resilience against mechanical stress, identifying potential weaknesses and vulnerabilities that could lead to failure.

By using our evaluation services, you can improve product reliability, reduce costs, enhance brand reputation, comply with industry standards, and increase efficiency. Our team of experts is committed to helping you refine your designs and optimize your manufacturing process, ensuring your products meet the highest standards of quality and performance.

Dont compromise on your PCBs performance under mechanical stress. Contact us today to learn more about our laboratory services and how we can help you improve product reliability and efficiency.