Verifying PCB Trace Widths for Signal Integrity

Verifying PCB Trace Widths for Signal Integrity Ensuring Reliable High-Speed Digital Systems

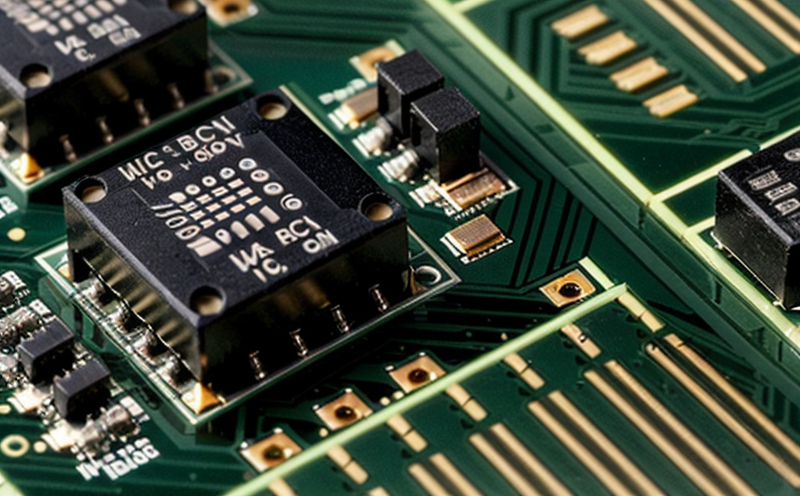

In todays fast-paced electronics industry, high-speed digital systems are increasingly critical to the success of businesses across various sectors. These systems rely on Printed Circuit Boards (PCBs) to facilitate data transmission at incredibly high speeds. However, ensuring signal integrity in these systems is a daunting task due to the complexity of PCB design and manufacturing processes.

The Importance of Signal Integrity

Signal integrity refers to the ability of a circuit or system to maintain its designed performance under various operating conditions. It encompasses factors such as noise, distortion, and attenuation that can impact signal quality and transmission speed. In high-speed digital systems, signal integrity is crucial for reliable data transfer, which in turn affects overall system performance, lifespan, and safety.

One critical aspect of PCB design that significantly impacts signal integrity is the trace width. Trace width refers to the physical dimension of a conductor on a PCB used for signal routing. It plays a vital role in determining the signals ability to transmit information accurately without degradation.

What is Verifying PCB Trace Widths for Signal Integrity?

Verifying PCB trace widths for signal integrity is a laboratory service provided by Eurolab that ensures your high-speed digital systems meet the required standards for reliability and performance. Our team of experts employs state-of-the-art equipment and methodologies to measure and analyze PCB trace widths, providing you with accurate data on their impact on signal integrity.

Advantages of Verifying PCB Trace Widths for Signal Integrity

Verifying PCB trace widths for signal integrity offers numerous benefits that can significantly enhance your business operations. Here are some key advantages

Improved System Performance By verifying PCB trace widths, you can ensure that your high-speed digital systems operate within the required specifications, leading to improved system performance and efficiency.

Reduced Maintenance Costs With accurate data on signal integrity, you can reduce maintenance costs associated with troubleshooting and repairing faulty systems.

Enhanced Safety Signal integrity is critical for ensuring the safety of electronic systems. Verifying PCB trace widths helps prevent potential hazards and ensure compliance with industry standards.

Increased Productivity By verifying PCB trace widths, you can identify and address potential signal integrity issues before they impact system performance, leading to increased productivity and competitiveness.

Compliance with Industry Standards Our laboratory service ensures that your systems meet or exceed industry standards for signal integrity, reducing the risk of regulatory non-compliance.

Key Benefits of Verifying PCB Trace Widths for Signal Integrity

Here are some key benefits of verifying PCB trace widths for signal integrity

Accurate Measurement and Analysis Our team employs state-of-the-art equipment to measure and analyze PCB trace widths, providing accurate data on their impact on signal integrity.

Customized Solutions We offer customized solutions tailored to your specific needs, ensuring that our laboratory service meets the unique requirements of your business.

Fast Turnaround Times Our efficient laboratory processes enable fast turnaround times, allowing you to quickly address potential signal integrity issues and ensure system reliability.

Expert Support Our team of experts is dedicated to providing exceptional support and guidance throughout the verification process, ensuring that you receive accurate results and actionable insights.

QA Frequently Asked Questions about Verifying PCB Trace Widths for Signal Integrity

Here are some frequently asked questions about verifying PCB trace widths for signal integrity

What is the purpose of verifying PCB trace widths?

Verifying PCB trace widths ensures that high-speed digital systems meet required standards for reliability and performance.

How does Eurolab verify PCB trace widths?

Our team employs state-of-the-art equipment and methodologies to measure and analyze PCB trace widths, providing accurate data on their impact on signal integrity.

What are the benefits of verifying PCB trace widths?

Verifying PCB trace widths improves system performance, reduces maintenance costs, enhances safety, increases productivity, and ensures compliance with industry standards.

How long does it take to receive results from Eurolabs laboratory service?

Our efficient laboratory processes enable fast turnaround times, allowing you to quickly address potential signal integrity issues and ensure system reliability.

Conclusion

Verifying PCB trace widths for signal integrity is a critical laboratory service that ensures the reliability and performance of high-speed digital systems. By partnering with Eurolab, you can benefit from our expertise, state-of-the-art equipment, and customized solutions tailored to your specific needs. Our team is dedicated to providing exceptional support and guidance throughout the verification process, ensuring that you receive accurate results and actionable insights.

At Eurolab, we understand the importance of signal integrity in high-speed digital systems. Thats why were committed to helping businesses like yours ensure system reliability and performance through our laboratory services. Contact us today to learn more about verifying PCB trace widths for signal integrity and take the first step towards improved system performance, reduced maintenance costs, enhanced safety, increased productivity, and compliance with industry standards.

This article aims to provide a comprehensive overview of the importance of verifying PCB trace widths for signal integrity and the benefits of partnering with Eurolab. By understanding the significance of signal integrity in high-speed digital systems, businesses can make informed decisions about their laboratory services and ensure system reliability and performance.

Call-to-Action

Are you looking for expert support to verify your PCB trace widths? Contact us today to learn more about our laboratory services and how we can help improve system performance, reduce maintenance costs, enhance safety, increase productivity, and ensure compliance with industry standards.