Testing for PCB Electromagnetic Interference (EMI)

Unlocking Peace of Mind Understanding the Importance of Testing for PCB Electromagnetic Interference (EMI)

In todays fast-paced and increasingly complex technological landscape, businesses are under pressure to develop innovative products that meet the ever-changing demands of the market. However, this pursuit of innovation can often lead to unforeseen challenges, particularly when it comes to ensuring the reliability and performance of electronic components. One such critical issue is Electromagnetic Interference (EMI), which poses a significant threat to the functionality and safety of Printed Circuit Boards (PCBs). In this article, we will delve into the world of EMI testing for PCBs and highlight why its essential for businesses to prioritize this laboratory service.

What is Testing for PCB Electromagnetic Interference (EMI)?

Electromagnetic Interference (EMI) occurs when an electronic device emits electromagnetic energy that interferes with other devices or systems. This can lead to malfunctions, data loss, and even physical harm. As a result, regulatory bodies such as the Federal Communications Commission (FCC) in the United States have established strict guidelines for EMI testing and compliance.

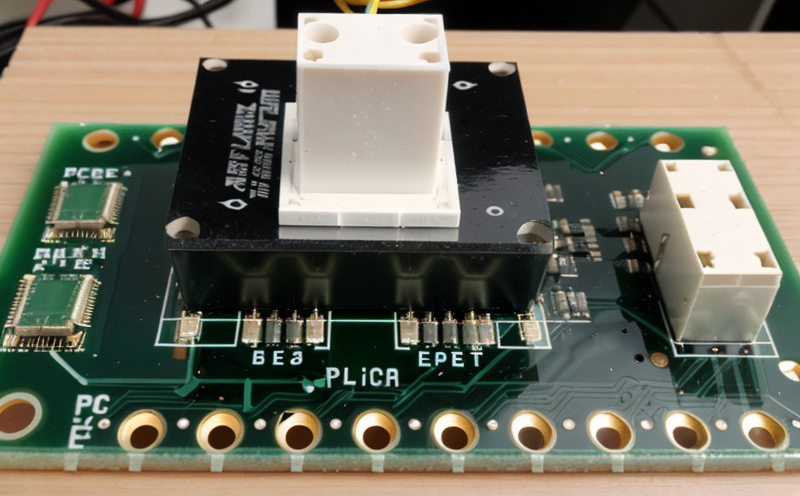

Testing for PCB Electromagnetic Interference (EMI) involves using specialized equipment and techniques to assess the level of electromagnetic radiation emitted by a PCB under various operating conditions. This laboratory service is designed to help businesses ensure that their products meet regulatory requirements, while also identifying potential issues before they reach the market.

The Advantages of Testing for PCB Electromagnetic Interference (EMI)

Incorporating EMI testing into your product development process offers numerous benefits, including

Compliance with Regulatory Requirements By conducting EMI testing, businesses can ensure that their products meet or exceed regulatory requirements, reducing the risk of fines and reputational damage.

Improved Product Reliability Identifying potential EMI issues early on enables companies to make necessary design modifications, resulting in more reliable and efficient products.

Reduced Costs Conducting EMI testing upfront can save businesses significant costs associated with redesigns, rework, or even recalls.

Enhanced Safety By minimizing electromagnetic radiation emitted by PCBs, businesses can ensure the safety of their customers and employees.

Key Benefits

Prevent Product Failure Identify potential EMI issues before they reach the market, reducing product failures and returns.

Improve Design Efficiency Streamline your design process with our expert analysis and recommendations.

Minimize Regulatory Risks Ensure compliance with regulatory requirements, avoiding costly fines and reputational damage.

How Does EMI Testing for PCBs Work?

Our laboratory team employs a range of techniques to assess the electromagnetic radiation emitted by a PCB under various operating conditions. These may include

Conducted Emissions (CE) testing Measures the level of electromagnetic energy radiated by the PCBs power cables.

Radiated Emissions (RE) testing Evaluates the level of electromagnetic energy radiated by the PCB itself.

Immunity testing Assesses a PCBs susceptibility to electromagnetic interference from external sources.

Our expert technicians use state-of-the-art equipment, including spectrum analyzers and antennas specifically designed for EMI testing. We work closely with our clients to ensure that their products meet or exceed regulatory requirements, providing detailed reports and recommendations for improvement.

QA Your Questions Answered

We understand that you may have questions about Testing for PCB Electromagnetic Interference (EMI). Here are some of the most frequently asked queries

What is the purpose of EMI testing?

EMI testing ensures that a PCB meets regulatory requirements, while also identifying potential issues before they reach the market.

How do I know if my product needs EMI testing?

If your product contains electronic components or operates at high frequencies, it may be subject to EMI regulations. Consult with our experts to determine if EMI testing is necessary for your product.

What are the typical costs associated with EMI testing?

The cost of EMI testing varies depending on the scope and complexity of the project. Our team will work closely with you to provide a customized quote tailored to your needs.

Conclusion

In conclusion, Testing for PCB Electromagnetic Interference (EMI) is an essential laboratory service that can help businesses ensure compliance with regulatory requirements, improve product reliability, reduce costs, and enhance safety. By partnering with Eurolab, you can unlock peace of mind knowing that your products meet the highest standards of electromagnetic compatibility.

Dont let EMI issues compromise your products performance or reputation. Contact us today to learn more about our Testing for PCB Electromagnetic Interference (EMI) services and how we can help you navigate the complex world of electromagnetic regulations.

Why Choose Eurolab?

At Eurolab, we pride ourselves on providing expert laboratory services that meet the unique needs of each client. With a team of experienced technicians and state-of-the-art equipment, we offer

Customized solutions Our experts work closely with you to tailor our EMI testing services to your specific product requirements.

Comprehensive reporting Detailed reports provide clear recommendations for improvement, ensuring that your products meet regulatory requirements.

Timely results We understand the importance of expedited results. Our team works efficiently to deliver timely and accurate test data.

Trust Eurolab with your Testing for PCB Electromagnetic Interference (EMI) needs. Contact us today to take the first step towards ensuring the reliability, performance, and safety of your products.