Adhesion Testing for Surface Mount Components in Harsh Conditions

Unlocking Reliable Performance in Harsh Environments Adhesion Testing for Surface Mount Components with Eurolab

In todays fast-paced and ever-evolving electronics industry, the demand for high-performance surface mount components is at an all-time high. These tiny yet mighty components are crucial to the efficient operation of modern electronic devices, from smartphones to industrial control systems. However, their performance can be severely compromised when exposed to harsh environmental conditions such as extreme temperatures, humidity, and vibrations.

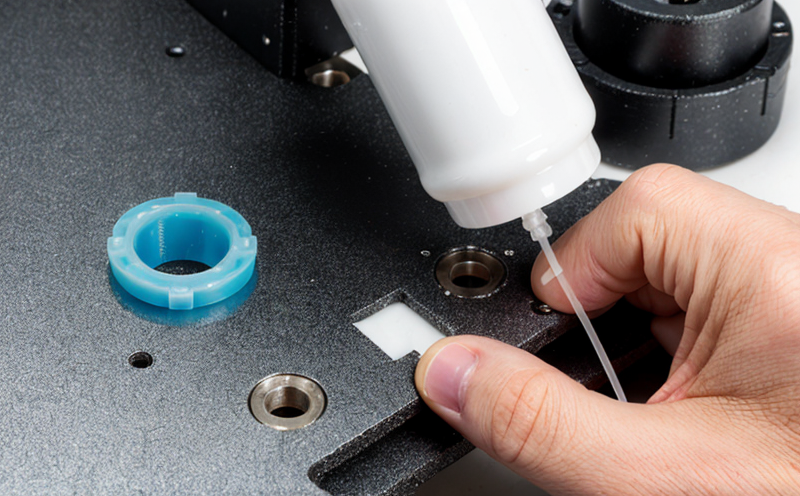

Adhesion testing for surface mount components in harsh conditions is a critical laboratory service that ensures these components meet the rigorous standards required for reliable performance in challenging environments. Eurolab offers this specialized service, providing businesses with peace of mind and enhanced product reliability.

The Importance of Adhesion Testing for Surface Mount Components

Surface mount components are notoriously prone to adhesion-related issues when subjected to harsh conditions. Delamination, cracking, and other forms of adhesion failure can lead to catastrophic consequences, including device malfunction, reduced lifespan, or even complete system failure.

Adhesion testing helps identify potential issues early on, allowing manufacturers to take corrective action before products hit the market. This proactive approach not only saves businesses time and money but also ensures consumer safety and satisfaction.

Benefits of Adhesion Testing for Surface Mount Components in Harsh Conditions

Eurolabs Adhesion Testing service offers numerous benefits that can transform your business

Enhanced Product Reliability By identifying potential adhesion-related issues, you can ensure your products meet the highest standards of reliability, even in harsh environments.

Reduced Warranty Claims and Liability With Eurolabs testing services, you can minimize warranty claims and associated liabilities, protecting your brand reputation and bottom line.

Improved Customer Satisfaction By guaranteeing reliable performance, you can increase customer satisfaction and loyalty, driving repeat business and positive word-of-mouth.

Cost Savings Early identification of potential issues saves time and money by preventing costly redesigns or rework.

Compliance with Industry Regulations Eurolabs testing services ensure your products comply with relevant industry standards and regulations, reducing the risk of costly recalls or fines.

Competitive Advantage By incorporating Adhesion Testing into your quality control process, you can differentiate your brand from competitors and establish a reputation for excellence.

Key Benefits of Working with Eurolab

Eurolabs team of expert technicians is dedicated to providing world-class testing services that meet the unique needs of your business. With our expertise and cutting-edge equipment, we offer

Customized Testing Solutions Our experienced team will work with you to develop a tailored testing plan that addresses specific adhesion-related concerns.

State-of-the-Art Equipment Eurolabs advanced testing facilities ensure accurate and reliable results, giving you confidence in the performance of your products.

Rapid Turnaround Times We understand the importance of timely results. Our team works efficiently to deliver reports and recommendations within tight deadlines.

Expert Analysis and Recommendations Our technicians provide clear explanations of test results, along with actionable recommendations for improving product reliability.

QA Adhesion Testing for Surface Mount Components in Harsh Conditions

Q What is Adhesion Testing?

A Adhesion testing measures the bond strength between a surface mount component and its substrate or adjacent components. This ensures that adhesives or solder joints remain intact even under harsh conditions.

Q Why is Adhesion Testing essential for my business?

A Adhesion-related issues can lead to costly product recalls, warranty claims, and damage to your brand reputation. By incorporating Adhesion Testing into your quality control process, you can minimize these risks and ensure reliable performance in challenging environments.

Q How does Eurolabs testing service differ from others?

A Our team of expert technicians and state-of-the-art equipment ensure accurate and reliable results. We also offer customized testing solutions tailored to your specific needs.

Q Can I test my own products using Adhesion Testing?

A While in-house testing can be beneficial, it may not provide the same level of accuracy or reliability as Eurolabs testing services. Our team has extensive experience and access to specialized equipment, ensuring you receive comprehensive and actionable results.

Conclusion

Adhesion testing for surface mount components in harsh conditions is no longer a nicety its a necessity. By working with Eurolab, businesses can ensure their products meet the highest standards of reliability, even when faced with challenging environmental conditions. Our expert team and state-of-the-art facilities provide world-class testing services that drive product innovation and protect your bottom line.

Dont let adhesion-related issues compromise your businesss success. Contact Eurolab today to learn more about our Adhesion Testing service and discover how we can help you unlock reliable performance in harsh environments.