Testing for Surface Mount Component Delamination

Unlock the Secrets of Surface Mount Component Delamination Why Testing Matters for Your Business

In todays fast-paced electronics industry, ensuring the reliability and integrity of electronic components is crucial to maintaining a competitive edge. One critical aspect that often goes unnoticed is surface mount component delamination (SMCD). This phenomenon can lead to catastrophic failures, costly rework, and damage to your brand reputation.

Eurolabs laboratory service, Testing for Surface Mount Component Delamination, is designed to help you identify potential issues before they become major problems. By investing in this essential testing service, youll be able to

Enhance product reliability

Reduce warranty claims and returns

Improve manufacturing efficiency

Comply with industry standards

What is Surface Mount Component Delamination?

Surface mount component delamination occurs when the bonding between the component and the printed circuit board (PCB) fails, causing the component to separate from the PCB. This can be due to various factors, including

Poor soldering techniques

Inadequate cleaning of the PCB surface

Incorrect storage or handling procedures

Material defects

Advantages of Testing for Surface Mount Component Delamination

Our laboratory service is specifically designed to detect SMCD issues in your electronic components. Here are just a few advantages of choosing Eurolabs Testing for Surface Mount Component Delamination

Early detection and prevention Our testing service enables you to identify potential delamination issues before they lead to costly failures or damage to your reputation.

Improved product reliability By detecting SMCD, you can take corrective actions to ensure the integrity of your electronic components, resulting in reduced warranty claims and returns.

Increased manufacturing efficiency With Eurolabs Testing for Surface Mount Component Delamination, youll be able to optimize your production processes by identifying areas where improvements can be made.

Compliance with industry standards Our service ensures that your products meet or exceed regulatory requirements, safeguarding your business against potential liabilities.

Cost savings By detecting SMCD early on, you can avoid costly rework and replacement of defective components, reducing waste and minimizing losses.

Enhanced supply chain reliability Eurolabs Testing for Surface Mount Component Delamination helps you build trust with your suppliers by ensuring that their products meet the required standards.

How Does Eurolabs Laboratory Service Work?

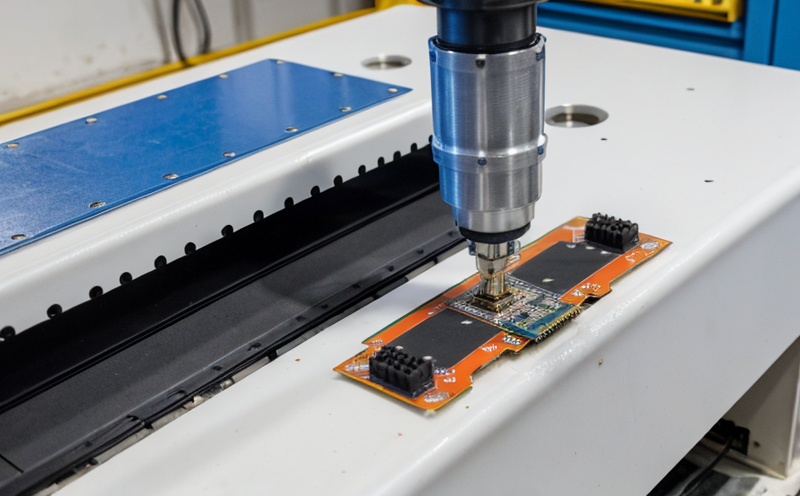

Our state-of-the-art laboratory employs cutting-edge technologies to detect surface mount component delamination. Heres a step-by-step overview of our testing process

Sample preparation We carefully collect and prepare your electronic components for analysis.

Visual inspection Our experienced technicians conduct a thorough visual examination of the components using high-resolution microscopes.

Advanced imaging techniques We utilize specialized imaging tools, such as scanning acoustic microscopy (SAM) or infrared (IR) spectroscopy, to detect potential delamination issues.

Data analysis and reporting Our team provides comprehensive reports outlining test results, identifying areas of concern, and offering recommendations for corrective action.

Frequently Asked Questions

We understand that you may have questions about Eurolabs Testing for Surface Mount Component Delamination service. Here are some answers to common queries

Q What types of electronic components can be tested?

A Our laboratory is equipped to test a wide range of surface mount components, including resistors, capacitors, inductors, and ICs.

Q How long does the testing process take?

A The duration of our testing service varies depending on the complexity of your samples. Typically, we can complete analysis within 24-48 hours.

Q What are the costs associated with Eurolabs laboratory service?

A Our pricing structure is based on the number and type of components tested, as well as any additional services required (e.g., sample preparation or data analysis).

Q Can I schedule a testing session at my facility?

A Yes, our team can arrange to perform testing at your premises if preferred.

Why Choose Eurolabs Testing for Surface Mount Component Delamination?

In todays competitive electronics industry, its essential to prioritize quality and reliability. By partnering with Eurolab, youll gain access to

State-of-the-art laboratory equipment

Expert technicians with extensive industry experience

Comprehensive reporting and data analysis

Cost-effective solutions tailored to your business needs

Dont let surface mount component delamination compromise the integrity of your electronic components. Choose Eurolabs Testing for Surface Mount Component Delamination and unlock the secrets to a more reliable, efficient, and profitable manufacturing process.

Get Started Today!

Take the first step towards ensuring the reliability and quality of your electronic components by contacting our team at Eurolab. Were committed to delivering exceptional laboratory services that meet or exceed your expectations.