Simulating Surface Mount Adhesion in Thermal Shock Conditions

Simulating Surface Mount Adhesion in Thermal Shock Conditions A Crucial Laboratory Service for Businesses

In todays fast-paced and competitive electronics industry, manufacturers face numerous challenges when it comes to ensuring the reliability and performance of their products. One critical aspect that often gets overlooked is the surface mount adhesion of components under thermal shock conditions. This phenomenon can have devastating consequences on a products lifespan and functionality, resulting in costly recalls, production delays, and damage to a companys reputation.

Thats where Eurolab comes in a leading laboratory services provider offering an essential solution Simulating Surface Mount Adhesion in Thermal Shock Conditions. By utilizing our state-of-the-art facilities and expert technicians, businesses can gain valuable insights into the thermal performance of their products, ensuring they meet the highest standards of quality and reliability.

Why is Simulating Surface Mount Adhesion in Thermal Shock Conditions Essential?

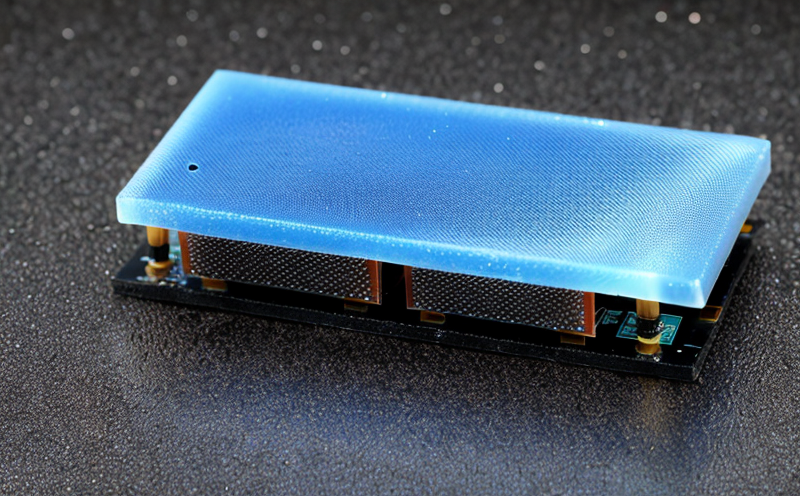

Thermal shock conditions occur when a component or product is exposed to sudden and extreme temperature changes. This can cause stress on the surface mount adhesion, leading to potential failures such as

Delamination The separation of components from the substrate

Cracking The formation of cracks within the material

Warping The deformation of the component or substrate

These issues can result in product malfunctions, reduced lifespan, and increased maintenance costs. By simulating surface mount adhesion under thermal shock conditions, manufacturers can

Advantages of Using Simulating Surface Mount Adhesion in Thermal Shock Conditions

Improved Product Reliability Identify potential weaknesses and areas for improvement before mass production

Increased Efficiency Reduce the risk of costly recalls and production delays by identifying issues early on

Enhanced Quality Control Ensure compliance with industry standards and regulations, such as IPC (Institute for Printed Circuits) and MIL-STD (MILITARY STANDARD)

Reduced Maintenance Costs Minimize repair and replacement costs by identifying potential failures before they occur

Compliance with Industry Regulations Meet the requirements of major manufacturers and regulatory bodies

Key Benefits

Predictive Analysis Identify potential failure modes and areas for improvement

Thermal Performance Optimization Enhance product performance under various temperature conditions

Component Validation Verify component reliability in real-world scenarios

Material Selection Choose materials with optimal thermal properties to ensure reliable performance

Failure Mode and Effects Analysis (FMEA) Identify potential failure modes and their effects on the products overall performance

How Does Simulating Surface Mount Adhesion in Thermal Shock Conditions Work?

At Eurolab, our team of experts uses advanced equipment and techniques to simulate surface mount adhesion under thermal shock conditions. The process involves

Sample Preparation Our technicians prepare your samples according to your specifications.

Testing We conduct testing using specialized equipment, such as the ESSAC (Environmental Stress Screening Accelerated Aging Chamber).

Data Analysis Our team analyzes the results and provides you with a comprehensive report outlining potential weaknesses and areas for improvement.

QA

Q What is the purpose of Simulating Surface Mount Adhesion in Thermal Shock Conditions?

A The primary goal is to evaluate the reliability and performance of products under extreme temperature conditions, ensuring compliance with industry standards and regulations.

Q How does Eurolab ensure the accuracy and reliability of the results?

A Our team uses advanced equipment and techniques, combined with rigorous quality control measures, to guarantee accurate and reliable results.

Q Can I customize the testing protocol to meet my specific needs?

A Yes, our experts will work closely with you to develop a customized testing plan tailored to your products unique requirements.

Q What kind of samples can be tested using this service?

A We can test various types of components and materials, including electronic devices, mechanical parts, and more.

Conclusion

In todays competitive business landscape, manufacturers must prioritize quality, reliability, and performance. By leveraging Eurolabs Simulating Surface Mount Adhesion in Thermal Shock Conditions laboratory service, businesses can

Enhance product reliability

Improve efficiency

Comply with industry regulations

Reduce maintenance costs

Dont let thermal shock conditions compromise your products integrity. Trust Eurolab to provide you with the expert knowledge and advanced facilities necessary to ensure your products meet the highest standards of quality and performance.

Insert Call-to-Action

Experience the benefits of Simulating Surface Mount Adhesion in Thermal Shock Conditions today. Contact us to learn more about our laboratory services and how we can support your business needs.