Testing for Solder Mask Interaction with Surface Mount Components

Testing for Solder Mask Interaction with Surface Mount Components A Crucial Service for Electronics Manufacturers

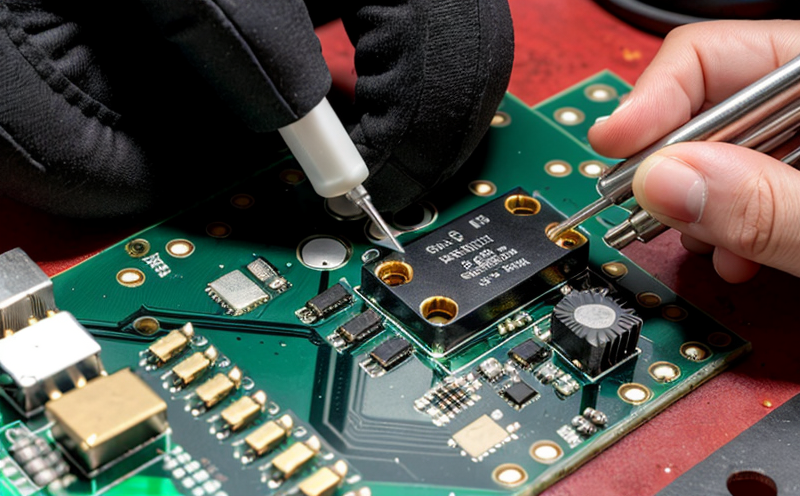

In todays fast-paced electronics industry, the reliability and performance of printed circuit boards (PCBs) are crucial to a companys success. One often-overlooked yet critical factor in PCB design is the interaction between solder mask and surface mount components. Solder mask, also known as conformal coating or solder resist, protects the PCB from moisture, corrosion, and electrical stress while ensuring reliable connections between components.

However, when not designed or manufactured correctly, the solder mask can interact with surface mount components (SMCs) in ways that compromise their performance, reliability, and lifespan. This phenomenon, known as Solder Mask Interaction (SMI), can lead to manufacturing defects, product failures, and costly rework or recalls.

Eurolabs comprehensive laboratory service, Testing for Solder Mask Interaction with Surface Mount Components, is designed to help electronics manufacturers identify potential SMI issues before they become major problems. This essential testing service ensures the reliability and quality of PCBs, enabling companies to meet stringent industry standards, improve product yields, and reduce warranty claims.

The Benefits of Eurolabs Testing for Solder Mask Interaction with Surface Mount Components

Our laboratory service offers numerous benefits that can significantly impact your business

Improved Product Reliability By identifying potential SMI issues early on, you can take corrective actions to prevent manufacturing defects, product failures, and costly rework or recalls.

Enhanced Quality Assurance Our testing services ensure compliance with industry standards, such as IPC-7251, which helps maintain your companys reputation for quality and reliability.

Increased Productivity By reducing the number of defective products and minimizing rework or recall efforts, you can focus on producing high-quality PCBs more efficiently.

Reduced Warranty Claims Our testing services help minimize the risk of warranty claims, which not only saves costs but also protects your companys reputation.

Key Benefits of Eurolabs Testing for Solder Mask Interaction with Surface Mount Components

Here are some key benefits that set us apart

Comprehensive Testing We provide a thorough analysis of your PCBs to identify potential SMI issues, including visual inspections, electrical testing, and chemical analysis.

Expert Analysis Our experienced technicians and engineers analyze test data to provide actionable recommendations for improving PCB design, manufacturing processes, or both.

Rapid Turnaround Times We understand the importance of timely results. Our laboratory is equipped with state-of-the-art equipment, enabling us to deliver fast turnaround times without compromising on accuracy or quality.

Customized Solutions We offer flexible testing packages and tailored services to meet your specific needs, from routine inspections to advanced research and development projects.

Frequently Asked Questions

Here are some answers to common questions about Eurolabs Testing for Solder Mask Interaction with Surface Mount Components

What is the purpose of testing for solder mask interaction?

The primary goal of our laboratory service is to identify potential issues between solder mask and surface mount components, ensuring the reliability and quality of your PCBs.

How do I know if my company needs this testing service?

If youre concerned about product failures, manufacturing defects, or costly rework or recalls related to SMI issues, our testing services can help alleviate these concerns.

What types of components are affected by solder mask interaction?

Surface mount components (SMCs) are most susceptible to solder mask interaction, including ICs, resistors, capacitors, and inductors.

Conclusion

In conclusion, Eurolabs Testing for Solder Mask Interaction with Surface Mount Components is a vital laboratory service that helps electronics manufacturers identify potential issues between solder mask and surface mount components. By using our comprehensive testing services, you can improve product reliability, enhance quality assurance, increase productivity, reduce warranty claims, and protect your companys reputation.

Dont wait until its too late contact Eurolab today to learn more about how we can help you ensure the quality and reliability of your PCBs.