Assessing the Bonding Integrity of SMT Pads

Assessing the Bonding Integrity of SMT Pads A Crucial Laboratory Service for Electronics Manufacturers

In todays fast-paced electronics industry, the demand for high-quality and reliable products is at an all-time high. To meet this demand, manufacturers must ensure that every component, including Surface Mount Technology (SMT) pads, meets stringent standards. However, with the increasing complexity of electronic devices, identifying potential issues in SMT pads can be a daunting task. This is where Assessing the Bonding Integrity of SMT Pads comes into play a critical laboratory service provided by Eurolab that helps electronics manufacturers ensure the reliability and performance of their products.

What is Assessing the Bonding Integrity of SMT Pads?

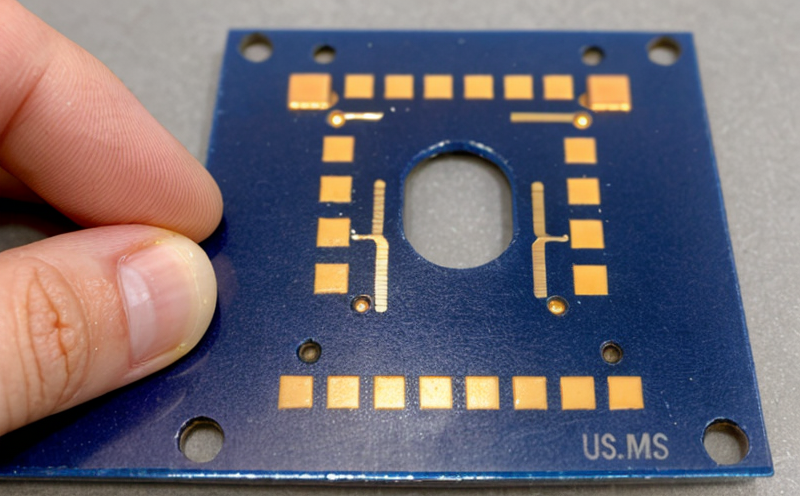

Assessing the Bonding Integrity of SMT pads involves evaluating the bonding quality between the pads surface and the attached component. This process is essential to determine if the bond is strong enough to withstand various environmental factors, such as temperature fluctuations, humidity, and mechanical stress. Eurolabs expert team uses advanced equipment and techniques to assess the bonding integrity of SMT pads, providing manufacturers with valuable insights into their products reliability.

Why is Assessing the Bonding Integrity of SMT Pads Essential for Businesses?

Incorporating Assessing the Bonding Integrity of SMT Pads into your quality control process offers numerous benefits. Here are some key advantages

Advantages of Using Assessing the Bonding Integrity of SMT Pads

Improved Product Reliability By identifying potential issues in SMT pads, manufacturers can ensure that their products meet the required standards for reliability and performance.

Reduced Warranty Claims Products with strong bonding integrity are less likely to experience failures, resulting in lower warranty claims and associated costs.

Increased Customer Satisfaction Manufacturers who offer high-quality products with reliable SMT pads can expect increased customer satisfaction and loyalty.

Enhanced Brand Reputation By prioritizing product quality and reliability, manufacturers can establish a strong brand reputation in the market.

Compliance with Industry Standards Assessing the Bonding Integrity of SMT Pads helps manufacturers meet industry standards for electronic components, ensuring compliance with regulations such as IPC (Institute for Printed Circuits) and IEC (International Electrotechnical Commission).

Additional Benefits

Cost Savings Identifying and addressing bonding integrity issues early on can save manufacturers significant costs associated with rework, replacement, or repair.

Increased Efficiency By streamlining the quality control process, manufacturers can reduce production time and increase overall efficiency.

Competitive Advantage Manufacturers who prioritize product quality and reliability can differentiate themselves from competitors and establish a competitive edge in the market.

How Eurolabs Assessing the Bonding Integrity of SMT Pads Service Works

Eurolabs team of experts uses advanced equipment, including microscopy and spectroscopy tools, to assess the bonding integrity of SMT pads. The process involves

Sample Preparation Eurolab receives SMT pads from manufacturers and prepares them for analysis.

Microscopic Examination The team examines the pad surface using high-resolution microscopes to identify any defects or irregularities.

Spectroscopy Analysis Advanced spectroscopy tools are used to analyze the chemical composition of the pad surface, identifying potential issues with bonding integrity.

Data Analysis and Reporting Eurolabs experts analyze the data collected during the analysis and provide comprehensive reports detailing the bonding integrity of each SMT pad.

Frequently Asked Questions (FAQs)

Q What types of SMT pads can be assessed?

A Eurolab can assess a wide range of SMT pads, including those made from various materials such as tin-lead, lead-free, and copper.

Q How long does the assessment process take?

A The duration of the assessment process varies depending on the complexity of the samples. Typically, results are available within 24 to 48 hours.

Q Can Eurolab provide certification for compliant SMT pads?

A Yes, Eurolab can provide certification and documentation for compliant SMT pads, which can be used for regulatory purposes.

Q What is the cost of the Assessing the Bonding Integrity of SMT Pads service?

A The cost of the service varies depending on the number of samples and complexity of the analysis. Please contact Eurolab for a customized quote.

In conclusion, Assessing the Bonding Integrity of SMT Pads is a critical laboratory service that helps electronics manufacturers ensure the reliability and performance of their products. By identifying potential issues with bonding integrity early on, manufacturers can reduce warranty claims, increase customer satisfaction, and establish a strong brand reputation in the market. Eurolabs expert team is dedicated to providing high-quality analysis and reporting services, helping businesses navigate the complex world of SMT pads. Dont wait contact Eurolab today to schedule your Assessing the Bonding Integrity of SMT Pads service and take the first step towards ensuring the reliability and performance of your products.