Testing for Surface Mount Adhesion in Extreme Pressure Environments

Testing for Surface Mount Adhesion in Extreme Pressure Environments A Crucial Service for Businesses

In todays fast-paced and highly competitive manufacturing landscape, ensuring the reliability and performance of electronic components is more critical than ever. One of the most significant challenges faced by manufacturers is the potential failure of surface mount adhesives under extreme pressure conditions. This can lead to catastrophic consequences, including equipment damage, product recalls, and reputational damage.

Eurolab offers a specialized laboratory service that addresses this critical need Testing for Surface Mount Adhesion in Extreme Pressure Environments. Our state-of-the-art facilities and expert technicians provide unparalleled accuracy and precision in evaluating the adhesion properties of surface mount adhesives under extreme pressure conditions.

The Importance of Surface Mount Adhesion

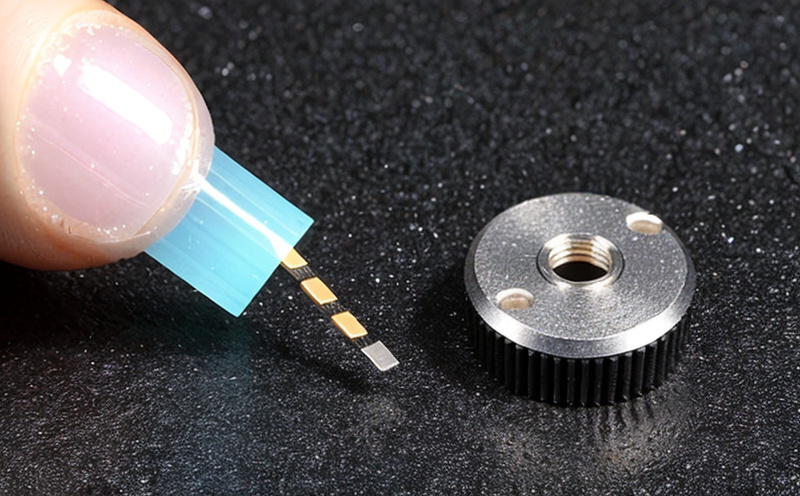

Surface mount adhesives play a vital role in ensuring the structural integrity and performance of electronic components, such as printed circuit boards (PCBs), microelectronic devices, and sensors. These materials bond the component to the substrate, providing mechanical stability and withstanding various environmental conditions, including temperature, humidity, and pressure.

However, extreme pressure environments can compromise the adhesion properties of these materials, leading to potential failures. This is particularly concerning in industries where equipment reliability and performance are paramount, such as

Aerospace and defense

Automotive

Medical devices

Industrial automation

Advantages of Using Eurolabs Testing for Surface Mount Adhesion

Our laboratory service offers a comprehensive range of benefits that can help businesses like yours ensure the reliability and performance of their electronic components. Here are some of the key advantages

Benefits

Prevent Equipment Failure Our testing services identify potential adhesion issues before they cause equipment failure, reducing downtime, and minimizing costs associated with repairs or replacement.

Ensure Regulatory Compliance By evaluating surface mount adhesives under extreme pressure conditions, we help businesses meet industry standards and regulations, avoiding costly fines and reputational damage.

Optimize Material Selection Our expert technicians provide detailed analysis and recommendations for selecting the most suitable surface mount adhesive materials for specific applications, ensuring optimal performance and reliability.

Reduce Product Returns By identifying adhesion issues early on, we help businesses reduce product returns, improve customer satisfaction, and maintain a competitive edge in the market.

How Eurolabs Testing for Surface Mount Adhesion Works

Our laboratory service is designed to simulate real-world extreme pressure conditions, providing a comprehensive evaluation of surface mount adhesive properties. Heres an overview of our testing process

Sample Preparation We receive samples of the surface mount adhesive materials from the client, which are then prepared and tested according to standard industry protocols.

Testing under Extreme Pressure Conditions Our state-of-the-art equipment simulates extreme pressure conditions, including high-temperature and humidity environments, to evaluate the adhesion properties of the surface mount adhesive.

Data Analysis and Reporting We provide detailed reports and analysis of the test results, including recommendations for optimizing material selection or adjusting manufacturing processes.

QA Section

We understand that our clients may have specific questions about our laboratory service. Here are some frequently asked questions (FAQs) to help address your concerns

Q What types of surface mount adhesives can be tested?

A We can test a wide range of surface mount adhesives, including epoxy-based, acrylic-based, and silicone-based materials.

Q How long does the testing process take?

A Our testing process typically takes 1-3 days to complete, depending on the complexity of the test and the availability of our equipment.

Q Can I request custom testing protocols or specific testing conditions?

A Yes! We can design customized testing protocols and conditions to meet your specific needs and requirements.

Q Do you provide recommendations for material selection and optimization?

A Absolutely! Our expert technicians will provide detailed analysis and recommendations for optimizing material selection, ensuring optimal performance and reliability.

Conclusion

In conclusion, Eurolabs Testing for Surface Mount Adhesion in Extreme Pressure Environments is a critical laboratory service that helps businesses ensure the reliability and performance of their electronic components. By providing unparalleled accuracy and precision, we help manufacturers prevent equipment failure, ensure regulatory compliance, optimize material selection, and reduce product returns.

Dont wait until its too late! Contact us today to learn more about our laboratory services and how they can benefit your business. Our expert technicians are ready to help you address the challenges of surface mount adhesion in extreme pressure environments.