Evaluating Adhesive Material Choices for Surface Mounting

Evaluating Adhesive Material Choices for Surface Mounting A Crucial Service for Businesses

In the fast-paced world of manufacturing and product development, one crucial aspect that often gets overlooked is the adhesive material used in surface mounting processes. Adhesives play a vital role in ensuring the structural integrity and reliability of products, but choosing the right adhesive can be a daunting task. This is where Evaluating Adhesive Material Choices for Surface Mounting comes into play a specialized laboratory service provided by Eurolab that helps businesses make informed decisions about their adhesive material selection.

In this article, well delve into the importance of evaluating adhesive material choices, explore the benefits of using surface mounting adhesives, and discuss how Eurolabs laboratory services can help your business achieve success. Whether youre a seasoned manufacturer or a startup looking to enter the market, understanding the significance of adhesive material evaluation is crucial for ensuring product quality, reducing costs, and staying competitive.

The Importance of Adhesive Material Evaluation

Adhesive materials are used in various industries, including automotive, aerospace, electronics, and construction, among others. The right adhesive can provide a strong bond between surfaces, ensuring stability and durability, while the wrong one can lead to failures, recalls, and even product liability issues. With so many types of adhesives available, its challenging for businesses to select the most suitable material without proper testing and evaluation.

Here are some reasons why evaluating adhesive material choices is essential

Product Reliability Adhesive failure can lead to product malfunctions, recalls, and damage to your brand reputation.

Cost Savings Choosing the right adhesive can help reduce production costs, as it eliminates the need for rework or replacement of faulty products.

Compliance with Regulations Adhesives must meet specific regulatory requirements in various industries. Evaluating adhesive material choices ensures compliance with relevant standards and regulations.

Increased Efficiency By selecting the most suitable adhesive, you can streamline your manufacturing process, reduce downtime, and improve productivity.

Benefits of Using Surface Mounting Adhesives

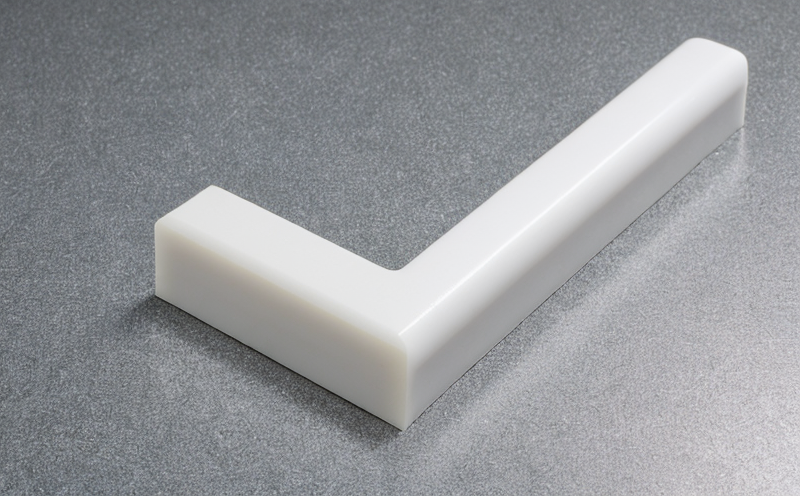

Surface mounting adhesives are designed for bonding components to surfaces, often in electronic devices or other precision applications. These adhesives offer numerous benefits, including

High Bond Strength Surface mounting adhesives provide strong bonds between surfaces, ensuring reliable connections and minimizing the risk of adhesive failure.

Low Viscosity These adhesives have low viscosity, making them easy to apply and flow into tight spaces.

Thermal Resistance Surface mounting adhesives can withstand high temperatures, reducing the risk of thermal degradation or delamination.

Resistance to Chemicals Many surface mounting adhesives offer resistance to chemicals, such as solvents, fuels, and cleaners.

Eurolabs Laboratory Services A Solution for Adhesive Material Evaluation

Eurolab offers a comprehensive laboratory service that evaluates adhesive material choices for surface mounting processes. Our team of experts uses state-of-the-art equipment and techniques to assess the performance of various adhesives under controlled conditions. We provide

Adhesive Selection Our experts help you select the most suitable adhesive for your specific application, taking into account factors such as temperature, humidity, and chemical exposure.

Performance Testing We conduct rigorous testing to evaluate the mechanical, thermal, and chemical properties of various adhesives.

Failure Analysis If adhesive failure occurs, our team investigates the root cause and provides recommendations for improvement.

QA Frequently Asked Questions about Evaluating Adhesive Material Choices

Q1 Why is evaluating adhesive material choices so crucial for businesses?

A1 Evaluating adhesive material choices ensures product reliability, reduces costs, and helps businesses comply with regulations.

Q2 What types of industries benefit from surface mounting adhesives?

A2 Surface mounting adhesives are commonly used in the automotive, aerospace, electronics, and construction industries, among others.

Q3 How does Eurolabs laboratory service help businesses select the right adhesive material?

A3 Our team of experts provides guidance on adhesive selection, conducts performance testing, and analyzes failure data to ensure the most suitable adhesive is chosen for each application.

Q4 Can Eurolabs laboratory services be customized to meet specific business needs?

A4 Yes, our services can be tailored to meet your unique requirements, ensuring that we address your specific challenges and provide actionable recommendations.

Conclusion

Evaluating adhesive material choices for surface mounting processes is a critical aspect of product development and manufacturing. By choosing the right adhesive, businesses can ensure product reliability, reduce costs, and comply with regulations. Eurolabs laboratory service provides a comprehensive solution for evaluating adhesive material choices, helping businesses make informed decisions about their adhesive selection.

Whether youre looking to improve your current adhesive materials or seeking guidance on selecting new ones, our team is here to help. Contact us today to learn more about how Eurolabs laboratory services can support your business needs and ensure the success of your products.

Final Thoughts

In a world where product quality and reliability are paramount, evaluating adhesive material choices is no longer a luxury but a necessity for businesses. By working with Eurolab, you can rest assured that your adhesive materials meet the highest standards, ensuring the long-term success of your products and business reputation.