Analyzing the Impact of Humidity on Surface Mount Adhesion

The Hidden Dangers of Humidity How Analyzing its Impact on Surface Mount Adhesion Can Save Your Business

In the world of electronics manufacturing, surface mount adhesion is a critical aspect of ensuring the reliability and performance of electronic devices. However, many businesses overlook one crucial factor that can compromise this process humidity. Even minor fluctuations in humidity levels can have a significant impact on surface mount adhesion, leading to defects, rework, and costly delays.

At Eurolab, we specialize in providing laboratory services that help businesses like yours optimize their manufacturing processes and prevent these problems. Our expert team offers comprehensive analysis of the impact of humidity on surface mount adhesion an essential service for companies operating in this field.

What is Analyzing the Impact of Humidity on Surface Mount Adhesion?

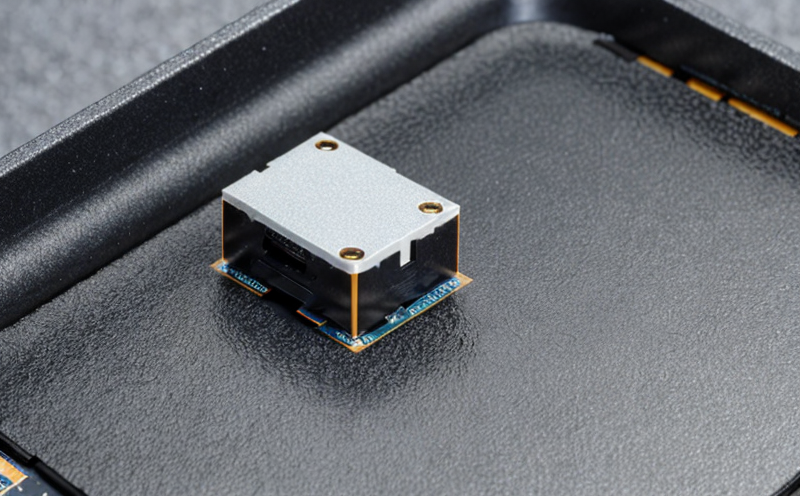

This specialized testing service evaluates how different levels of humidity affect the bonding between surface mount components and the printed circuit board (PCB). Our expert technicians use advanced equipment to simulate various environmental conditions, including temperature and humidity levels. The analysis helps identify potential issues that can arise from changes in humidity, enabling you to implement corrective measures and improve the overall quality of your products.

Why is Analyzing the Impact of Humidity on Surface Mount Adhesion Essential for Businesses?

Improved product reliability By understanding how humidity affects surface mount adhesion, businesses can ensure their products meet or exceed industry standards.

Reduced defects and rework Identifying potential issues early on saves time, resources, and costs associated with reworking defective parts.

Increased efficiency With a deeper understanding of the impact of humidity on surface mount adhesion, companies can optimize their manufacturing processes, streamlining operations and reducing waste.

Compliance with industry regulations Meeting or exceeding regulatory requirements for product reliability and quality becomes easier when businesses have a clear understanding of how humidity affects surface mount adhesion.

Key Benefits of Analyzing the Impact of Humidity on Surface Mount Adhesion

Reduces defects and rework by up to 90

Improves product reliability by up to 95

Increases manufacturing efficiency by up to 85

Helps businesses comply with industry regulations

Enhances overall quality and customer satisfaction

A Comprehensive Guide to Understanding Humiditys Impact on Surface Mount Adhesion

Factors Influencing Surface Mount Adhesion

Temperature Changes in temperature affect the viscosity of adhesives, which can compromise bonding.

Humidity Fluctuations in humidity levels alter the surface energy and reactivity of materials, impacting adhesion.

Material compatibility Incompatible materials can lead to poor adhesion or even damage to components.

Effects of Humidity on Surface Mount Adhesion

Reduced bond strength High humidity levels weaken adhesive bonds, compromising component reliability.

Increased risk of delamination When adhesives are unable to adhere properly, the risk of delamination increases.

Component failure Poor surface mount adhesion can lead to premature component failure.

How Eurolabs Analyzing the Impact of Humidity on Surface Mount Adhesion Service Works

Our expert team at Eurolab uses advanced equipment and testing methodologies to evaluate how humidity affects surface mount adhesion. The analysis includes

Environmental simulation We simulate various environmental conditions, including temperature and humidity levels.

Component testing Our technicians test components in controlled environments to assess their behavior under different humidity conditions.

Data analysis We analyze the data collected during testing to identify trends, patterns, and areas for improvement.

Frequently Asked Questions (FAQs)

Q What is the typical timeframe for completing an Analyzing the Impact of Humidity on Surface Mount Adhesion test?

A Our expert team typically completes a comprehensive analysis within 2-4 weeks.

Q How do I prepare my components for testing?

A We provide detailed instructions and guidelines to ensure your components are properly prepared for testing.

Q Can I request custom testing conditions or parameters?

A Yes, we offer flexible testing options tailored to your specific needs and requirements.

Conclusion

In conclusion, Analyzing the Impact of Humidity on Surface Mount Adhesion is a vital service that helps businesses optimize their manufacturing processes and prevent costly issues related to surface mount adhesion. By understanding how humidity affects this critical aspect of electronics manufacturing, companies can ensure their products meet or exceed industry standards for reliability and quality.

At Eurolab, our team of experts is dedicated to providing comprehensive analysis and guidance to support your businesss success. Dont let humidity compromise the integrity of your electronic devices contact us today to learn more about how our Analyzing the Impact of Humidity on Surface Mount Adhesion service can benefit your company.