Thermal Cycling and its Effect on Surface Mount Adhesion

The Crucial Role of Thermal Cycling in Ensuring Surface Mount Adhesion

In the fast-paced world of electronics manufacturing, ensuring the reliability and longevity of electronic components is paramount. One critical aspect of this process is thermal cycling, a laboratory service that evaluates the impact of repeated temperature fluctuations on surface mount adhesion. At Eurolab, our team of experts offers comprehensive thermal cycling testing to help businesses safeguard their products against thermal stress, thereby minimizing the risk of failure and ensuring compliance with industry standards.

What is Thermal Cycling?

Thermal cycling refers to the process of exposing electronic components to repeated temperature fluctuations between extreme highs and lows. This simulation mimics real-world conditions, where components are subjected to various temperatures due to environmental factors such as changing weather patterns or malfunctioning cooling systems. By subjecting components to thermal cycling, manufacturers can assess their performance under stress conditions and identify potential weaknesses.

The Importance of Thermal Cycling in Surface Mount Adhesion

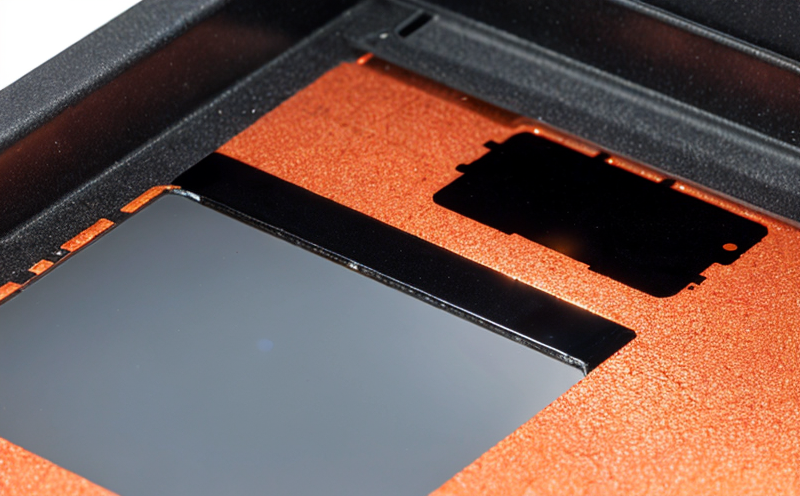

Surface mount adhesion is a critical factor in electronic component reliability. The bond between the component and its substrate must withstand various stresses, including temperature fluctuations, vibration, and humidity. However, even the smallest defects or imperfections can compromise this bond, leading to reduced product lifespan and performance.

Thermal cycling testing helps identify these potential issues by simulating extreme temperature conditions that would otherwise occur over a much longer period in real-world applications. By evaluating surface mount adhesion under thermal stress, manufacturers can

Minimize the risk of component failure Thermal cycling reveals weaknesses in the bond between components and substrates, enabling manufacturers to take corrective action before products are shipped.

Ensure compliance with industry standards Major industries such as automotive, aerospace, and consumer electronics require electronic components to withstand specific temperature ranges. Eurolabs thermal cycling testing ensures that your products meet or exceed these requirements.

Reduce warranty claims and product returns By identifying potential issues early on, manufacturers can avoid costly product recalls and minimize warranty claims.

Improve product reliability Thermal cycling helps identify areas for improvement in component design, material selection, and manufacturing processes, leading to more reliable products.

Benefits of Eurolabs Thermal Cycling Service

Our laboratory offers a comprehensive thermal cycling service that includes

Wide temperature range Our testing equipment can simulate temperatures ranging from -65C to 300C, covering a broad spectrum of potential operating conditions.

Highly accurate results Our team uses advanced instrumentation and software to ensure precise measurements and reliable data.

Expert analysis and reporting Our experienced engineers provide in-depth analysis and clear recommendations for improvement.

Flexible testing protocols We can customize thermal cycling tests to meet specific industry requirements or customer needs.

Common Applications of Thermal Cycling

Thermal cycling is used across various industries, including

Automotive electronics Electronic components must withstand extreme temperatures encountered during engine operation.

Aerospace electronics Components are exposed to harsh temperature fluctuations in aircraft and spacecraft environments.

Consumer electronics Devices such as smartphones, laptops, and gaming consoles require reliable surface mount adhesion under various operating conditions.

Frequently Asked Questions (FAQs)

Q What is the purpose of thermal cycling testing?

A Thermal cycling evaluates the impact of repeated temperature fluctuations on electronic component reliability, identifying potential weaknesses in surface mount adhesion.

Q How does Eurolabs thermal cycling service differ from others in the market?

A Our laboratory offers a comprehensive suite of services, including expert analysis and reporting, flexible testing protocols, and highly accurate results.

Q What types of temperature ranges can your equipment simulate?

A Our equipment can test components over temperatures ranging from -65C to 300C.

Q Can you customize thermal cycling tests for specific industry requirements or customer needs?

A Yes, we offer flexible testing protocols tailored to meet individual client needs.

Q How long does the thermal cycling process typically take?

A The duration of thermal cycling testing varies depending on the test conditions and equipment used. Our experienced team will work with you to determine the most efficient testing schedule for your project.

Conclusion

In todays competitive electronics manufacturing landscape, ensuring product reliability is crucial. Thermal cycling testing is a critical step in evaluating surface mount adhesion under extreme temperature conditions. By partnering with Eurolab, businesses can

Minimize component failure risk

Ensure compliance with industry standards

Reduce warranty claims and product returns

Improve product reliability

Dont compromise on the reliability of your products trust Eurolabs comprehensive thermal cycling service to safeguard their performance under various operating conditions. Contact us today to learn more about our laboratory services.