Surface Mount Adhesion Testing for High-Reliability Applications

Ensuring High-Reliability in Electronics The Critical Role of Surface Mount Adhesion Testing

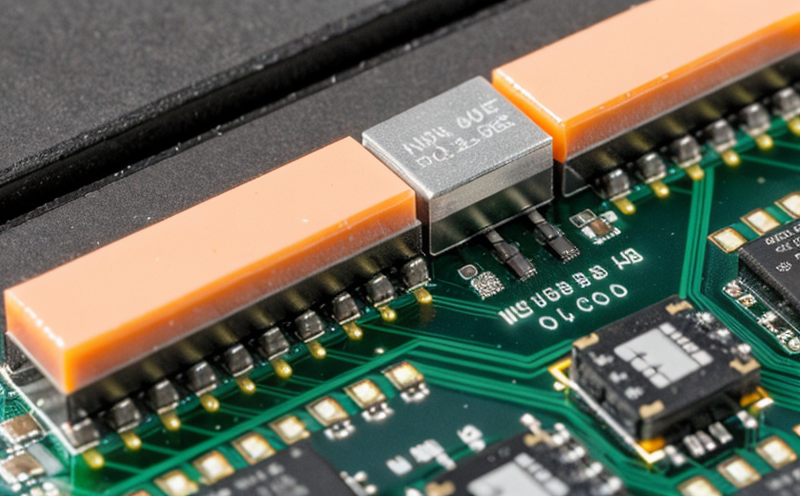

In todays fast-paced electronics industry, where reliability and efficiency are paramount, ensuring the integrity of components is crucial for businesses to remain competitive. One critical aspect often overlooked is the adhesion between surface mount devices (SMDs) and their respective substrates. Eurolabs Surface Mount Adhesion Testing for High-Reliability Applications provides a comprehensive solution to this problem.

The Significance of Surface Mount Adhesion Testing

Surface mount technology (SMT) has revolutionized electronics manufacturing by enabling faster production cycles, smaller device footprints, and increased efficiency. However, this process also introduces new challenges, particularly concerning the adhesion between SMDs and their substrates. Weak adhesion can lead to a range of issues, including

- Component Failure Loosened components may become dislodged during handling or thermal cycling, resulting in costly production line stoppages.

- Manufacturing Delays Troublesome rework processes caused by weak adhesions contribute significantly to overall manufacturing times.

- Reliability Risks Components with poor adhesion are more prone to electrical and mechanical failures, which can lead to significant downtime and repair costs.

The Advantages of Eurolabs Surface Mount Adhesion Testing

Eurolab offers a cutting-edge service that addresses these challenges head-on. By providing a detailed analysis of the adhesion between SMDs and their substrates, our team enables businesses to

- Prevent Component Failure Identify potential issues early in the production process, ensuring components meet high-reliability standards.

- Optimize Manufacturing Processes Implement corrective actions to improve component handling, storage, and assembly methods.

- Enhance Product Reliability Reduce the risk of premature failures by identifying and addressing adhesion-related weaknesses.

Key Benefits

- Improved Efficiency Streamline your manufacturing process with a deeper understanding of component-substrate interactions.

- Reduced Costs Avoid costly rework processes and production line stoppages associated with faulty components.

- Increased Competitiveness Demonstrate commitment to quality by adhering (no pun intended) to the highest standards in electronics reliability.

How Does Eurolabs Surface Mount Adhesion Testing Work?

Our team employs a combination of state-of-the-art equipment and proven methodologies to analyze the adhesion between SMDs and their substrates. This includes

- Shear Testing Measures the force required to dislodge components from their substrate, providing an objective assessment of adhesion strength.

- Peel Testing Evaluates the resistance of the adhesive bond to peeling forces, further understanding component-substrate interactions.

Addressing Your Questions About Surface Mount Adhesion Testing

Q What types of components can be tested?

A Our service is applicable to a wide range of SMDs, including but not limited to

- Resistor networks

- Capacitors

- Inductors

- Integrated circuits (ICs)

- MEMS devices

Q How does the testing process affect my production schedule?

A Minimal downtime is required for component collection and return. Our team works closely with your operations department to ensure seamless integration into existing workflows.

Q What kind of data can I expect from the test results?

A Detailed reports will be provided, including adhesion strength values and recommendations for process improvements based on our findings.

Why Choose Eurolabs Surface Mount Adhesion Testing Service?

By entrusting your surface mount adhesion testing needs to Eurolab, you gain access to

- Expertise Our team has extensive experience in analyzing component-substrate interactions.

- Cutting-Edge Equipment Stay ahead of the curve with the latest in testing technology.

- Customized Solutions We work closely with clients to tailor our services to meet specific needs and requirements.

Conclusion

Surface Mount Adhesion Testing for High-Reliability Applications is a critical service that ensures your electronics components meet the highest standards of reliability. By partnering with Eurolab, you can prevent costly production issues, optimize manufacturing processes, and enhance product reliability. Dont compromise on quality choose Eurolab for peace of mind in your electronics manufacturing operations.

Get Started Today

Take the first step towards higher efficiency, reduced costs, and increased competitiveness by contacting us to learn more about our Surface Mount Adhesion Testing service. Together, we can ensure that your products meet the highest standards of reliability, setting you apart from competitors and cementing your position as a leader in electronics manufacturing.